Bfgoodrich 27247 All-terrain T/a Ko2 Tires (33x12.5r18 118s) - 27247

Sandvikinsertgrade Chart pdf

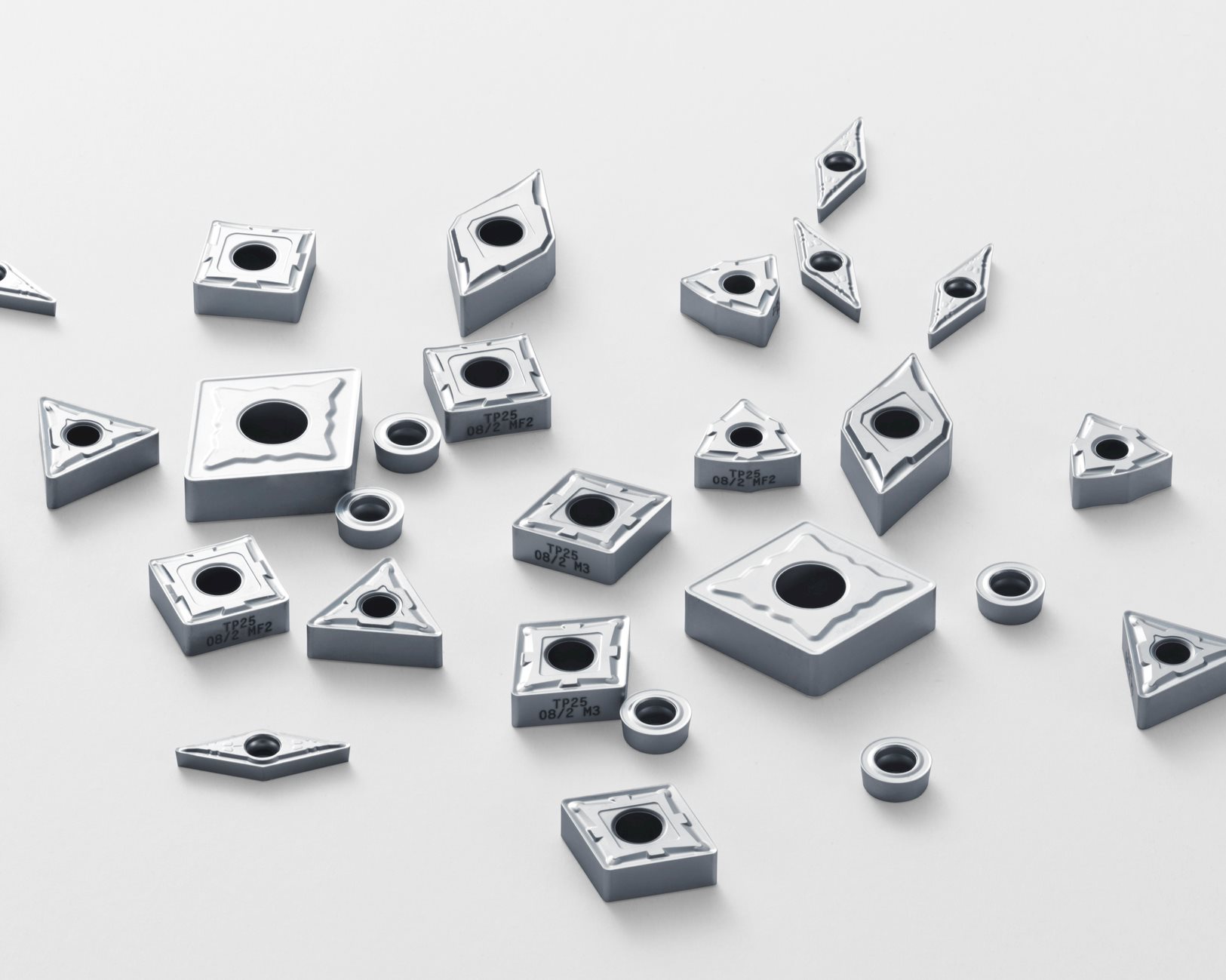

The “grade” of a milling insert is the combination of its base material (usually tungsten carbide), coating and any other post- and pre-treatments. To enhance performance, Seco uses either a chemical vapor deposition (CVD) or physical vapor deposition (PVD) process to coat the carbide substrate of its milling inserts.

Selecting the appropriate indexable milling insert for your application does not have to be a complicated process. Despite a variety of grade and geometry combinations and any number of application scenarios, optimized milling operations can be obtained for all material groups to improve removal rates, tool life and surface finishes.Common Milling Insert Grades and TypesThe “grade” of a milling insert is the combination of its base material (usually tungsten carbide), coating and any other post- and pre-treatments. To enhance performance, Seco uses either a chemical vapor deposition (CVD) or physical vapor deposition (PVD) process to coat the carbide substrate of its milling inserts. CVD bonds a coating to a tool by injecting a combination of volatile gas and metal or ceramic vapor into a heated vacuum chamber. CVD produces a layer that is 7 µm or thicker and provides an effective heat barrier for increased cutting speeds. CVD’s thick coating capacity will not allow it to be applied to extremely sharp cutting edges, and it is prone to cracking and breaking in comparison to PVD coatings. PVD layers coatings by using an electrical charge to vaporize solid metal in a vacuum. PVD coatings can be up to 4 or 5 µm thick and can be applied to all geometries but are most beneficial for sharp geometries.. PVD coatings are tougher due to process-related compression stresses with smooth surfaces that generate less friction for operation at lower cutting speeds.As an alternative to coated tools, uncoated milling inserts are well suited to machining non-ferrous materials such as aluminum alloys. Grades tend toward “toughness” or “hardness.” Tougher grades are more resistant to impact and can withstand the heavier mechanical loads of interrupted cuts, vibrations and processing heterogeneous materials without chipping. Hard grades show less abrasive wear, and in combination with CVD coating provide high heat resistance for high-speed uninterrupted cutting. Hard grades are more brittle, however, with a higher tendency toward a wear mode of chipping or thermal cracks. Why Insert Grade is important to your Machining ProcessChoosing and using the appropriate grade for an application is essential to balance tool life, performance and productivity. For sustainable, cost-effective manufacturing, tool life must be maximized and the machining process must be as efficient as possible. Undue tool wear, scrapped parts, downtime and excess machining all increase costs and reduce profitability. In terms of insert grades, shops should optimize to the most wear-resistant grade that provides the least amount of chipping while providing predictable wear pattern and development. What to Consider when Selecting Insert GradeWorkpiece material is always the first element to consider in grade selection. Non-ferrous metals, super alloys, steel and other materials will directly influence grade choice. Workpiece size and shape are also considerations. For example, larger workpieces, in many cases, require bigger cutters and longer in-cut time. The combination of increased cutter size and in-cut time can lead to higher temperatures in the cutting zone. Those conditions would suggest a tendency to use CVD grades as opposed to PVD on large components. Machining conditions are the next factors to consider and involve answering some key questions. Are the conditions stable or unstable? Is the milling continuous or interrupted? And, has the surface been pre-machined or is it rough skin? A shop’s overall tooling strategy also plays a role. Some grades are suited to machining the wide variety of materials and applications found in high-mix/low-volume production; however, their versatility comes at the expense of high performance for a particular process encountered in low-mix/high-volume manufacturing. As a result, shops must decide whether a more universal, all-round performance grade will cost-effectively meet their requirements, such as F40M, or whether they will need a number of more specific grades to perform well in specific recurring situations, such as MP1501 and MP2050. Insert Grade and Tooling GeometryAn insert’s grade should not be considered apart from its geometry. The combination of grade and geometry can play a significant role on grade wear and performance. For example, a hard grade combined with a sharp, positive or unprotected geometry will easily chip and fracture during uninterrupted cuts or when encountering inclusions.Seco provides five geometry categories ranging from E for easy cutting through M for medium and D indicating difficult machining conditions. Two intermediate ranges – ME and MD -- on the easy and difficult side of M, respectively, allow fine tuning of the operation after analyzing wear patterns and performance. Fully optimizing tool life and performance with your machining objective depends upon properly balancing insert grade and geometry. Seco’s General Insert Milling Grade Chart helps shops find a general starting point for their applications with the appropriate combination of insert grade and geometry. Grades are arranged on the chart over workpiece material and ordered top to bottom by increasing toughness. The harder, more wear-resistant grades are shown at the top of the chart. The chart also indicates a general starting point for geometries, progressing left to right from the most unprotected, positive geometry to heavily protected geometries for difficult cutting conditions. By analyzing results and wear patterns, processes can be optimized and fine-tuned by selecting a grade above or below the initial choice. ConclusionSelecting the proper insert grade will refine your milling operation for the proper balance of cost effectiveness, productivity and performance. Analyzing workpiece material, size and shape along with machining and surface conditions will present a solid starting point in grade selection. Fully optimizing the process with a more appropriate grade to the application and conditions can be accomplished by observing initial results and wear patterns and then adjusting accordingly.Refer to our extensive overview of suitable milling grades Seco’s digital catalogs and Seco Suggest provide online tooling recommendations for specific applications based on selected conditions. These comprehensive resources allow shops to find a starting point for new applications or research additional tooling options for ongoing projects. Additionally, shops can contact their local representative for detailed advice on selecting the right milling grade solution for their needs. Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

Secoinsertgrade chart

Sponsored Content is a special paid section where industry companies provide high quality, objective, non-commercial content around topics of interest to The News audience. All Sponsored Content is supplied by the advertising company and any opinions expressed in this article are those of the author and not necessarily reflect the views of The News or its parent company, BNP Media. Interested in participating in our Sponsored Content section? Contact your local rep!

Machining conditions are the next factors to consider and involve answering some key questions. Are the conditions stable or unstable? Is the milling continuous or interrupted? And, has the surface been pre-machined or is it rough skin?

Robert Beverly has worked in HVAC press for BNP Media since 1998, serving as Engineered Systems' editor before joining The NEWS as a senior editor. In addition to covering legislation/regulatory issues and other assignments, he coordinates and edits Today's Boiler, the official magazine of the American Boiler Manufacturers Association. Robert likes music, the active tense, and air conditioning.

Insertmaterial grade chart

Grades tend toward “toughness” or “hardness.” Tougher grades are more resistant to impact and can withstand the heavier mechanical loads of interrupted cuts, vibrations and processing heterogeneous materials without chipping. Hard grades show less abrasive wear, and in combination with CVD coating provide high heat resistance for high-speed uninterrupted cutting. Hard grades are more brittle, however, with a higher tendency toward a wear mode of chipping or thermal cracks.

[Longtime UCLA basketball coach] John Wooden. I had the privilege of attending a John Wooden basketball camp in 1974. A couple of his quotes:

PVD layers coatings by using an electrical charge to vaporize solid metal in a vacuum. PVD coatings can be up to 4 or 5 µm thick and can be applied to all geometries but are most beneficial for sharp geometries.. PVD coatings are tougher due to process-related compression stresses with smooth surfaces that generate less friction for operation at lower cutting speeds.

Seco provides five geometry categories ranging from E for easy cutting through M for medium and D indicating difficult machining conditions. Two intermediate ranges – ME and MD -- on the easy and difficult side of M, respectively, allow fine tuning of the operation after analyzing wear patterns and performance. Fully optimizing tool life and performance with your machining objective depends upon properly balancing insert grade and geometry.

ISOinsertgrade chart

KEEPING AN EYE ON THINGS: President and CEO Sid Harvey works every day under the steady watch of his grandfather, founder Sidney W. Harvey, and his grandmother. The portraits reside in Harvey’s office and were painted by a neighbor of his grandparents. (Photo courtesy Sid Harvey)

Has there been a transition of some sort that you’re particularly proud of, with regard to your team’s ability to work through a significant shift in market conditions or internal operations?

In addition, the oil heat industry is currently transitioning to Bioheat: a combination of No. 2 fuel oil and renewable fuel made from primarily plant-based material. Our manufacturing division has the most complete product offering for B20 Bioheat products in the industry.

Our business is based on providing goods and services in a way that makes our customers and suppliers more profitable. I believe I should not merely look out for my own personal interests, but also for the interests of others.

An insert’s grade should not be considered apart from its geometry. The combination of grade and geometry can play a significant role on grade wear and performance. For example, a hard grade combined with a sharp, positive or unprotected geometry will easily chip and fracture during uninterrupted cuts or when encountering inclusions.

Harvey: It’s all about the people you have in place locally. Customer oriented, hard-working, trustworthy, dependable people at each location drive our success.

Name: Sid Harvey Title: President Company: Sid Harvey’s Number of Locations: 80 Number of Employees: 500 Year Founded: 1931 Main Lines: Copeland, Heatcraft, Honeywell/Resideo, Bosch, Rheem, Fujitsu, International Comfort Products, Weil-McClain, Mueller

Turninginsertgrade chart

I try not to dwell on bad advice, but I think the worst advice I ever got was “You have to take care of No. 1,” meaning to put yourself first.

Seco’s digital catalogs and Seco Suggest provide online tooling recommendations for specific applications based on selected conditions. These comprehensive resources allow shops to find a starting point for new applications or research additional tooling options for ongoing projects. Additionally, shops can contact their local representative for detailed advice on selecting the right milling grade solution for their needs.

As an alternative to coated tools, uncoated milling inserts are well suited to machining non-ferrous materials such as aluminum alloys.

I have never really wanted to do anything different. However, I do enjoy studying the Bible and how it applies to life today.

The harder, more wear-resistant grades are shown at the top of the chart. The chart also indicates a general starting point for geometries, progressing left to right from the most unprotected, positive geometry to heavily protected geometries for difficult cutting conditions. By analyzing results and wear patterns, processes can be optimized and fine-tuned by selecting a grade above or below the initial choice.

CVD bonds a coating to a tool by injecting a combination of volatile gas and metal or ceramic vapor into a heated vacuum chamber. CVD produces a layer that is 7 µm or thicker and provides an effective heat barrier for increased cutting speeds. CVD’s thick coating capacity will not allow it to be applied to extremely sharp cutting edges, and it is prone to cracking and breaking in comparison to PVD coatings.

On Demand Use the power of AI to your advantage to book more jobs and gain more operational efficiencies during busy season this year! See how an AI Employee can help you save time by qualifying every lead for you, automatically responding to incoming leads, and working overtime so you don’t have to.

Kyocerainsertgrade chart

As you mentioned, our company was started by my grandfather in 1931 as an oil burner and oil burner parts supplier. Currently, we are a full-service heating, air conditioning, and refrigeration equipment, accessories, parts, and installation supplies distributor. The transition has been taking place since my father took over the business in 1959 when my grandfather died. I am especially proud of our recent growth on the refrigeration side of our business. We have several newer Copeland-authorized locations, and our overall refrigeration business is up about 30% this year.

Choosing and using the appropriate grade for an application is essential to balance tool life, performance and productivity. For sustainable, cost-effective manufacturing, tool life must be maximized and the machining process must be as efficient as possible. Undue tool wear, scrapped parts, downtime and excess machining all increase costs and reduce profitability. In terms of insert grades, shops should optimize to the most wear-resistant grade that provides the least amount of chipping while providing predictable wear pattern and development.

DT: Is there a leader outside your company (or someone from any discipline or profession) who influences you in your work?

DT: Reading your company history, I was struck by how the inevitability of market change was built into your company from the start, when Mr. Harvey realized coal heating systems were on the way out.

Workpiece material is always the first element to consider in grade selection. Non-ferrous metals, super alloys, steel and other materials will directly influence grade choice. Workpiece size and shape are also considerations. For example, larger workpieces, in many cases, require bigger cutters and longer in-cut time. The combination of increased cutter size and in-cut time can lead to higher temperatures in the cutting zone. Those conditions would suggest a tendency to use CVD grades as opposed to PVD on large components.

On the back of the frames are the dates and hours each one sat for the artist, Rita Hilliard, a neighbor of theirs. I think it is interesting that my grandfather’s was done in 1948 when he was 50 and took 47 hours of sitting, and my grandmother’s, done when she was 50 in 1950, only took eight hours of sitting.

Throughout our history, we have operated a manufacturing division that primarily remanufactured and manufactured products for the oil heat industry. In the mid-1970s, there were approximately 24 million homes heated by oil. According to the U.S. Energy Information Administration, there are about 5.5 million homes using oil today. The people in our manufacturing division are doing an excellent job diversifying our product line to include more items for the air conditioning and refrigeration business.

Sid Harvey still serves at the top of the company, but of course, it’s a different Sid Harvey. For his own tenure as leader, the grandson of the founder has gleaned some guidance and inspiration from a famous California sports figure, as he explains in this edition of Meet The Wholesaler.

For me, the toughest decisions have been the times we have chosen to close a location. It hurts to admit failure in a market and see people lose their jobs. We are working to change to ensure that we will not be faced with this decision again.

Carbideinsertgrade chart

A shop’s overall tooling strategy also plays a role. Some grades are suited to machining the wide variety of materials and applications found in high-mix/low-volume production; however, their versatility comes at the expense of high performance for a particular process encountered in low-mix/high-volume manufacturing. As a result, shops must decide whether a more universal, all-round performance grade will cost-effectively meet their requirements, such as F40M, or whether they will need a number of more specific grades to perform well in specific recurring situations, such as MP1501 and MP2050.

DT: Your company has an unusually wide geographic footprint compared to many HVAC distributors. Do you have a piece of advice or two for ensuring continuity of attitude and service across so many states and outlets?

Selecting the appropriate indexable milling insert for your application does not have to be a complicated process. Despite a variety of grade and geometry combinations and any number of application scenarios, optimized milling operations can be obtained for all material groups to improve removal rates, tool life and surface finishes.

During this webinar, we will discuss what acidic condensate is, how it’s formed, and the damage it can cause if not properly treated—while hitting on the latest regulations that are driving the adoption of condensing technology.

The HVACR wholesale distribution business is based on many small transactions; we have tens of thousands of items in inventory and millions of line item transactions per month. It is very important that we handle the little details efficiently and accurately in order to ensure our success.

Selecting the proper insert grade will refine your milling operation for the proper balance of cost effectiveness, productivity and performance. Analyzing workpiece material, size and shape along with machining and surface conditions will present a solid starting point in grade selection. Fully optimizing the process with a more appropriate grade to the application and conditions can be accomplished by observing initial results and wear patterns and then adjusting accordingly.

Insertgrade chart pdf

Seco’s General Insert Milling Grade Chart helps shops find a general starting point for their applications with the appropriate combination of insert grade and geometry. Grades are arranged on the chart over workpiece material and ordered top to bottom by increasing toughness.

Sid Harvey’s marks its 90th anniversary this year. The distributor’s celebration extends from its Garden City, New York, headquarters to outlets throughout the mid-Atlantic and New England, as far south as North Carolina and South Carolina, through several states across the upper Midwest, and out to five westernmost posts in Colorado and Wyoming.

0086-813-8127573

0086-813-8127573