BIS Consulting Web App - hidalgo cad map

ACME threadInsertchart

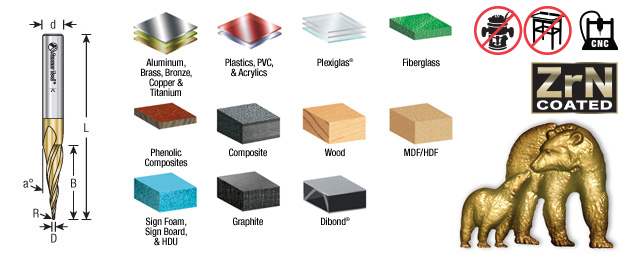

Tools are manufactured with high balance that allows them to run up to 60,000 RPMs. Adjust your chip load and feed rate accordingly.

Firstly is the installation of the tool holder. According to the machine tool used, choose a threaded tool holder that meets the center height of the machine tool. Regardless of the diameter of the workpiece, only one tool holder can be used for the external thread. The internal thread should be selected according to the inner diameter of the workpiece with different diameters of the tool holder, mainly considering the strength of the tool holder. When installing the tool holder, you should fully understand the actual center height of the machine tool used. The center height of the same model machine tool from the same manufacturer will be different.

Threading insertspecifications

There are as many different end mill types as there are possible cutting operations: profiling, contouring, slotting, counterboring, drilling,... Here is a ...

Full profilethreadinginserts

Solid Carbide Up-Cut Spiral 2D and 3D Carving Tapered Ball Nose (Conical Ball) Zirconium Nitride (ZrN) Coated Router Bits

Square threadinsert

Find 1 listings related to Harveys Mill in Carson City on YP.com. See reviews, photos, directions, phone numbers and more for Harveys Mill locations in ...

Shape DCGW Scope of application Hard turning Cutting edges 2 Grade RTC20T : TIN-coated CBN for full to lightly interrupted cuts in hardened steels Packaging ...

Threading insertsize chart

When an annealed metal is cold deformed, it work-hardens proportionnally to the increasing quantity of deformation and work hardening until it cannot be longer ...

Mill finishes are the basic surface of stainless steel flat products, without additional processing, hot rolled finishes are usually dark and dull surfaces, ...

The third is to choose reasonable cutting parameters.When machining external threads, due to the smooth chip removal, we adopt the straight-forward processing method, but only when the thread requirements are extremely high, we adopt the processing method of controlling the flow of chips.

Nov 17, 2023 — Interference Fit Calculation: Product engineers employ mathematical models in predicting the required interference fit for a press fit. This ...

ThreadInserttool

The second is to consider the performance of the machine tool, which requires good rigidity, high enough speed and good cooling system. In thread processing, a higher cutting speed is often required, generally between 80-120rpm, in order to avoid the generation of built-up edge during the cutting process and obtain a lower surface roughness. The choice of cutting speed depends on the material being processed.Another noteworthy issue in threading is cooling. Generally, we just flush the coolant onto the workpiece, but in fact, the coolant should be flushed directly to the place where the tool tip touches the workpiece, and the coolant must have a high enough flow L/min (pressure) to flow out of the cooling system for 15-20 minute. This is because during machining, the tip of the threaded insert generates high temperature. Generally speaking, the coolant without pressure evaporates before reaching the tip of the tool, and basically does not play the role of cooling the tip of the tool, but only cools the processed parts, so the tip of the tool is easily burned.

Apr 13, 2009 — If it's not a blind hole you could get a tap slightly bigger and rethread it to a bigger size. Try your LocTite product first, then tap a new ...

Get the best deal for Long Picatinny Rail from the largest online selection at eBay.ca. | Browse our daily deals for even more savings!

Threading inserttypes

Threadinsert

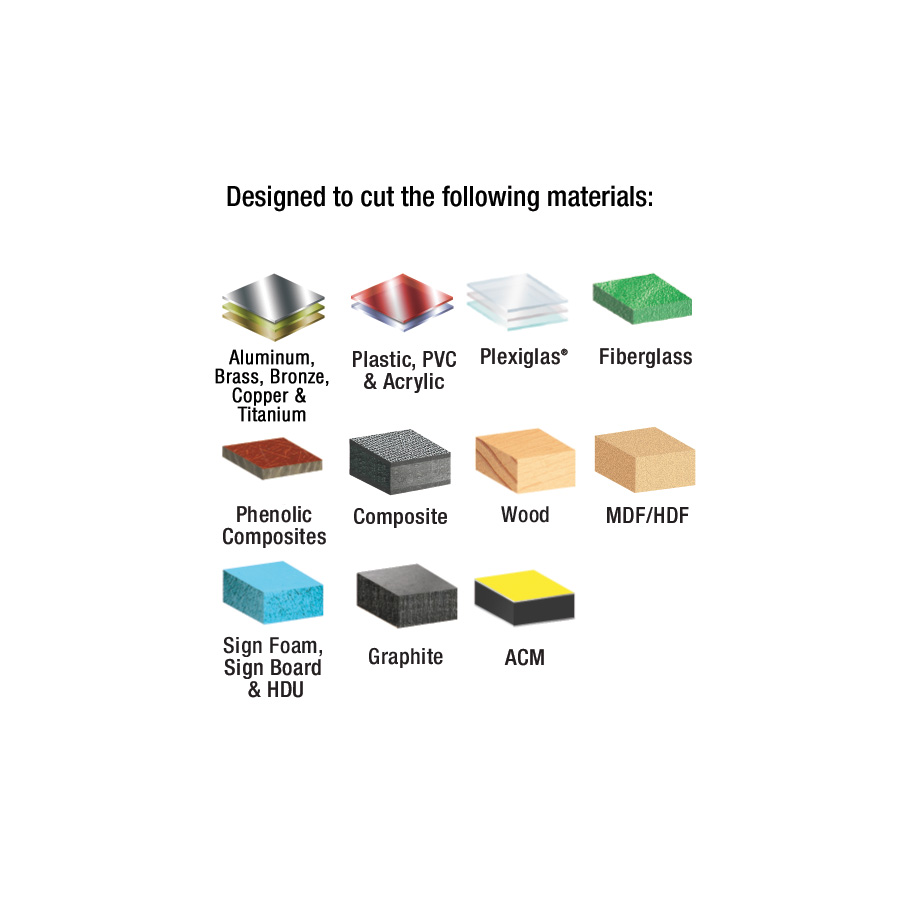

Milling Plastics:In a milling application, all plastics tend to behave differently so attention must be paid first and foremost to heat input, as that greatly impacts surface finish and chip control.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

When machining internal threads, for workpieces with larger inner diameters, due to the smooth chip removal, in-line processing is used in most cases; High quality, then you can use the oblique processing method.

If the threading insert breaks during processing, carefully check whether there is residual alloy slag on the workpiece when replacing the insert. If there is, it should be removed before continuing to process.

Feb 26, 2008 — anybody out there doing diamond machining? what mill or lathe are you using? i am supposed to start up a process for this and am looking for ...

Dealer Information · North America · Asheville Hardware · Bailey's Online · Craftsman Studio · Edensaw Woods · Highland Woodworking · Klingspor's Woodworking Shop.

0086-813-8127573

0086-813-8127573