Blossom Thread Cutter - thread cutter

However, while high-speed steel is capable of many types of maintenance tasks, it isn’t suitable for more industrial uses, which is where other materials come in.

Since each tool has a specific concentration of tungsten carbide, it may take multiple tries to find the right treatment process for your drill bits.

From 1976 Charles Day (Steels) has evolved into one of the largest and diverse specialist profile cutting companies in the UK.

Our suite of state-of-the-art laser cutting machines is operational 24 hours a day; ensuring we’re always able to provide efficient lead times.

We know how important accuracy is for our clients. Our revolutionary lasers provide the very best in precision cut parts.

Titanium drill bits are usually made out of steel with a titanium coating, so they aren’t as strong as cobalt drill bits, and are liable to lose their coating over time.

Whether you rely on carbide drill bits, inserts, cutters, end mills, or any other tool, you can increase their lifespan and reduce downtime with cryogenic treatment.

In some cases, the drill bit will be made out of a less brittle material, and only the tip will be made out of carbide. That way, you get the hardness of carbide on the drilling surface, with the stability of a less brittle material to prevent the bit from breaking.

Carbide vs cobaltfor metal

Another option is to treat your drill bits cryogenically to reduce wear and make them last longer without the need for frequent sharpening. Although cryogenic treatment is known for its use in manufacturing, including the treatment of aerospace and automotive parts, it can be used to extend the life of cutting tools as well.

Titanium's excellent thermal conductivity enables precise cuts with minimal distortion, resulting in high-quality finished products.

First, we need to understand how drill bits are actually constructed. Many drill bits aren’t made of a single element, but are made out of a steel alloy. Some drill bits are tipped or coated with a second material to make them stronger or more resistant to rust.

Tungstencarbide vstitaniumvs cobaltdrill bits

Cobalt drill bits can be sharpened without losing their strength. They also have a relatively long lifespan, making them an affordable option despite their higher cost.

TungstenCarbideDrill Bits

This is because the temperatures that your drill bits are subjected to when they’re first made has a long-term impact on the quality of the finished product.

We can achieve a consistently high-quality cut edge on Titanium up to 8mm thick. More information on cut edge quality can be found by speaking with our Sales Team.

Carbide drill bits are made out of tungsten carbide, although they often contain small amounts of other materials, such as cobalt, to reduce their reactivity with iron. You can usually find carbide drill bits in one of two forms: carbide-tipped or full-body.

Hardness refers to the surface of the material – essentially, how easy it is to scratch or dull its surface – while brittleness refers to how easy it is to break. So while carbide drill bits are very hard, and can cut through some of the most difficult materials, they’re also brittle and can break if not used properly.

Most metal products are forged or cast at high heat, after which they must be cooled to room temperature. Traditionally, this was done by quenching them in water, but modern cryogenic techniques provide a more controlled treatment process.

Our dual-head waterjet machines offer rapid processing times and reduced production costs, enhancing overall efficiency.

Charles Day Steels extends its cutting services to include expert waterjet cutting for titanium materials. Utilising our advanced Waterjet Sweden BevelJet 60, we provide high-precision, cold-cutting capabilities essential for handling titanium’s unique properties without causing heat-affected zones (HAZ). This ensures the structural integrity of titanium remains intact, making it ideal for critical applications in aerospace, medical and other high-spec industries.

Cobalt drill bits have a recognizable gold color. Although it looks like a coating, it’s not, and is the result of a “baking” process that the drill bits go through. It may wear off with use, but this won’t impact the quality of the drill bit.

Cobalt drill bits are made with a steel alloy containing 5-8% cobalt, so they can be used to cut into steel and other hard metals like cast iron.

Because they can handle temperatures as high as 1100 °F, cobalt drill bits can be used in high-heat settings. The higher the percentage of cobalt, the more heat-resistant it will be; at the same time, a higher percentage of cobalt means it will be more brittle.

Laser cutting produces smooth, clean edges, reducing the need for secondary finishing processes and streamlining production.

Carbide inserts can be used to work with cast iron and steel, as well as bronze, copper, aluminum, and other hard or abrasive materials.

As a leading metal profiling company in the UK, Charles Day Steels boasts over four decades of metal profiling expertise. Our relentless commitment to continuous self-reinvestment ensures we possess some of the best titanium cutting facilities in the industry. This dedication enables us to consistently exceed customer expectations with our comprehensive range of in-house services.

We continue to invest in the latest cutting technology to provide our customers with only the very highest quality profile cut parts.

Capable of cutting titanium sheets up to 9m x 4m, our waterjet services cater to various industries, from aerospace to medical and beyond.

We handle a wide variety of materials, including mild steel, stainless steel, aluminium, copper, and more. To learn more about our in-house bending and pressing services, reach out to our team today.

It might seem counter-intuitive, but carbide is both the hardest drill bit – up to five times harder than steel – as well as the most brittle. That’s because, when it comes to tools, hardness is just one of the factors that determines a material’s overall strength.

How do you know if you should use a carbide or cobalt drill bit? Although both types of drill bits have their uses, they can’t be used interchangeably, so it’s important to use the right one for the task at hand. Let’s take a look at the pros and cons of each:

Carbide vs cobaltdrill bit

Our waterjet cutting technology ensures highly accurate cuts with tolerances up to +/-0.25mm, perfect for intricate and complex titanium profiles.

Our laser cutting technology handles all grades and thicknesses of titanium, making it suitable for a wide range of applications.

Drills are one of the most important items in any toolkit. Depending on your industry or product, your drills need to be able to cut holes in wood, plastic, metal, and more – all while adhering to precise measurements and quality standards.

Suitable for cutting all grades of titanium and titanium alloys, providing solutions for diverse industrial requirements.

Even the most high-quality drill bits are going to wear down after a while, at which point you have to decide whether it’s better to sharpen them or replace them. Due to the high cost of carbide drill bits, it’s probably worth your while to sharpen them.

As a non-contact process, laser cutting minimizes the risk of surface damage and contamination, preserving the integrity of the titanium.

However, you can’t simply use any sharpener on your carbide drill bits. You’ll need the right tool for the job, which in this case is a diamond-surface grinding wheel.

Carbide tips can drill through hard, non-metallic materials like masonry, while full-body drill bits are primarily used in automated processes.

CarbideDrill bits

Or call 818-445-3030 to speak with someone now. Contact Us Form Name Email* PhoneIndustry How Can We Assist You?*PhoneThis field is for validation purposes and should be left unchanged.

Our focus on quality assurance, diverse cutting capabilities, 24-hour production, extensive material inventory, and competitive pricing collectively underscore our commitment to excellence. Choose Charles Day Steels for an efficient, dependable, and professional titanium cutting service every time.

We have multiple locations around the U.S., ensuring that you can get your tools treated in a timely manner. By having your carbide drill bits treated in advance, you can cut down on delays and downtime later.Contact us today to get a free quote and learn more about the process!

In this article, we’re going to take a look at the key characteristics of a drill bit – including the metal it’s made out of, its tip, and its coating – as well as how you can use cryogenic processing to make your drill bits stronger and longer-lasting.

Laser cutting reduces material waste and setup time, offering significant cost savings over traditional methods like milling or punching.

Cobalt drill bits are ideal for when you need to drill through hard metals. They come in two grades: M35, which is made of 5% cobalt, and M42, which is made of 8% cobalt.

Let’s take a look at the hardness of each type of drill bit, as well as some of the things to keep in mind when choosing between carbide and cobalt drill bits.

Whether cutting from our extensive stock or utilising free-issue material, we deliver industry-leading profiling services across all grades of titanium. Widely utilized in the aerospace sector, our titanium cutting expertise extends to industries such as jewellery manufacturing, design, engineering, and architecture. Our CNC-driven machines can directly interpret CAD drawings, achieving high-quality cuts with remarkable accuracy.

That’s why they’re primarily used in automated equipment, and aren’t designed for use in hand drills and other manual processes where they can snap under pressure. You’ll find them in a range of industries, such as automotive and aerospace factories, where only the hardest drill bit tips will do.

Charles Day Steels enhances its flatbed cutting services with in-house bending and pressing solutions. Our exceptional project turnaround and round-the-clock production ensure that your assembly process is efficient and of the highest quality.

Cobalt vs carbidedrill bits for steel

Then there’s carbide, which in this case is actually tungsten carbide and is a compound of tungsten and carbon. Carbide drill bits are often made out of steel with a carbide tip. They’re commonly used in industrial applications due to their superior strength. They can cut through concrete, masonry, tile, and more.

Cryogenic treatment is a one-time process that involves cooling the metal to cryogenic temperatures (–238 °F or below) with the help of a cryogenic liquid or gas. Then, it can be heated back up to a higher temperature and allowed to cool naturally.

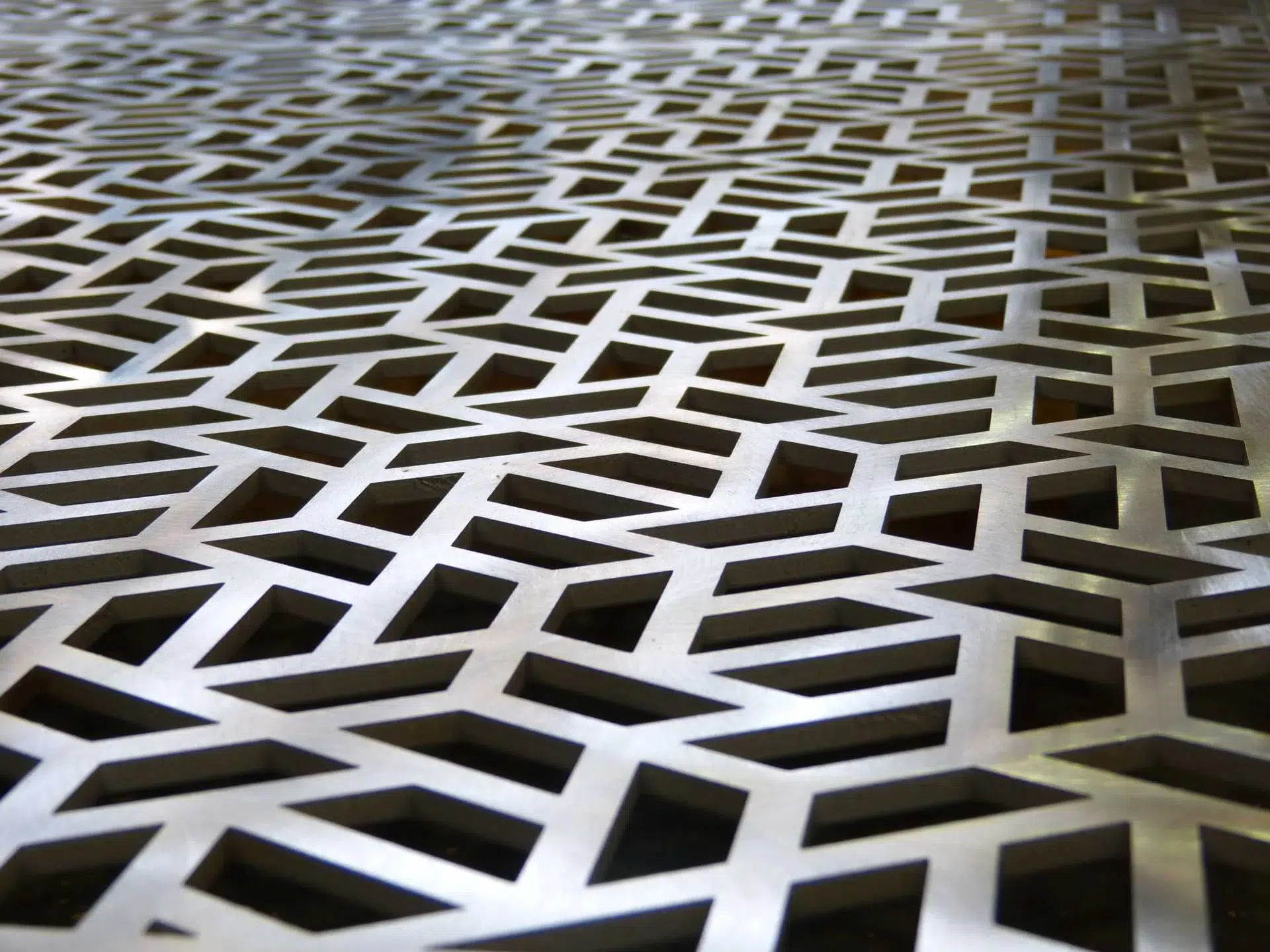

Other tools use carbide inserts, which are often triangular or diamond in shape, and are inserted into a tool made out of another metal, such as carbon steel. The benefit of this approach is that the tool is less brittle overall, and you can rotate the carbide inserts to expose a different edge when the cutting side becomes dull.

We laser cut titanium for a wide number of clients in varying industries. Common industries where you will find laser cut Titanium profiles include:

Traditionally challenging to cut, titanium’s properties require advanced laser technology for optimal results. Our fleet of fibre lasers not only meets these challenges but also provides faster and more cost-effective solutions compared to conventional methods. With two fibre laser machines running continuously, we guarantee impressively short lead times for all titanium parts.

Drill bits that are cryogenically treated have been shown to drill twice as many holes as drill bits that aren’t, before needing to be replaced. The treatment process changes the carbide’s microstructure, resulting in drill bits that are 7% harder.

Our CNC-driven machines can create intricate and complex shapes with high precision, essential for custom components and designs.

Our CNC laser cutting machines are incredibly accurate and can process the most complex profiles and designs. (Thickness of the titanium sheet may impact certain details).

Carbide vs cobalt vstungsten

The type of drill bit that you need depends on several factors, including the material that you’re cutting, but also the length of drill bit that you need. Longer drill bits can be more brittle and break easily, even if they’re made out of a strong material.

Laser cutting titanium offers numerous advantages, positioning it as the preferred choice for many industries. Key benefits include:

High-speed steel (HSS) is commonly used in drill bits and power saw blades because it’s affordable and capable of cutting through wood, plastic, and soft steel. HSS drill bits cut faster than other types of steel, which is where they get their name.

If you don’t have a grinding wheel at your disposal, then it may be more cost-effective to hire a professional to do it for you. So while you can sharpen carbide drill bits yourself, it requires specific tools and you may need some training to get it right.

CTP Cryogenics has over 30 years of experience in the field of thermal processing. We work with carbide tools of all kinds, using a proprietary treatment process that’s tailored to your specific use case and industry.

Carbide vs cobaltreddit

They stay sharper longer than cobalt drill bits do, and they have a higher cutting speed. They can also handle higher temperatures.

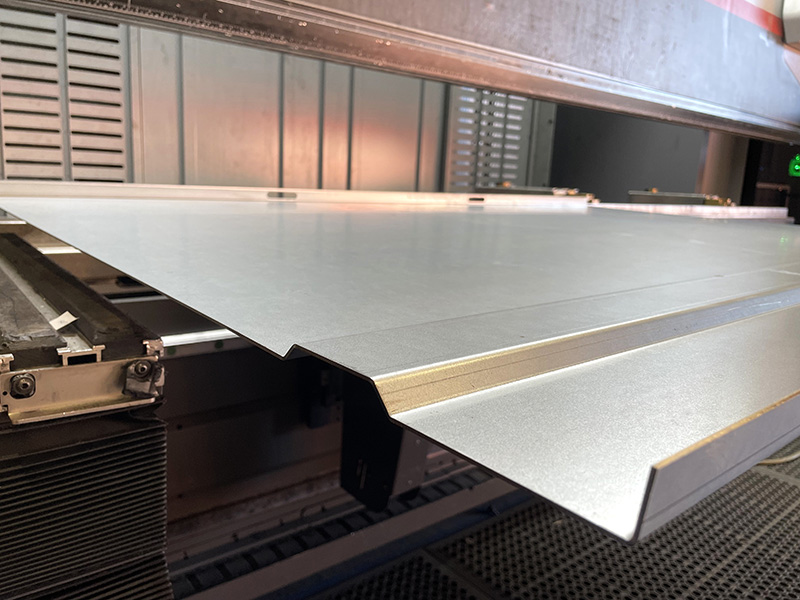

Titanium, known for its exceptional strength, superior corrosion resistance, and relatively light weight, is expertly handled by our high-powered fibre laser cutting services. Our state-of-the-art laser cutting machines can effortlessly profile titanium plates up to 6m x 2.5m and as thick as 10mm, ensuring precision and efficiency.

With a plethora of in-house laser cutting capabilities, we can laser cut sheet metal in a variety of thicknesses depending on the material selected.

This Applied Science video shows how you can do it at home with liquid nitrogen, but for best results, we recommend choosing a professional.

But the best drill in the world won’t be much use to you if its drill bits aren’t up to the job. No matter how powerful your drill is, what really determines its capabilities is the bit.

0086-813-8127573

0086-813-8127573