Boring Bars - bore bar

In conclusion, choosing the right grooving inserts for your cutting needs requires careful consideration of material compatibility, cutting conditions, chip control, tool holder compatibility, and budget constraints. By taking these factors into account, you can select a grooving insert that will optimize your cutting operations and improve efficiency and quality. Consult with a cutting tool expert or manufacturer for guidance on selecting the best grooving insert for your specific application.

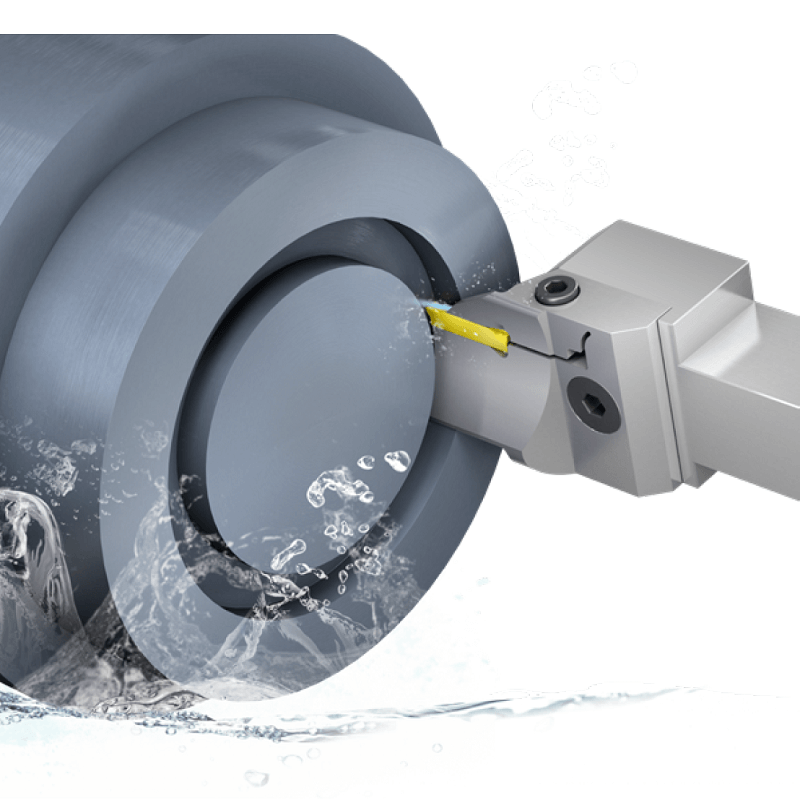

When it comes to grooving inserts for cutting tools, choosing the right one can make a significant difference in the efficiency and quality of your machining operations. Grooving inserts are used in a variety of applications, from turning and boring to threading and parting off. With so many options available on the market, it can be overwhelming to determine which grooving insert is best suited for your specific cutting needs. Here are some factors to consider when selecting the right grooving inserts for your cutting operations.

I’ve considered super glue hopefully wicking between the wood and insert. If it works it’ll make the threaded insert repair more difficult.

Also considering attempting to epoxy something to the insert, but there’s not much meat exposed, and I’ll probably end up epoxying the screw to the insert.

Since hex head is really hard to distinguish metric vs imperial, I forced myself to use only metric for hex/allen. I don’t want to carry both metric and imperial hex in my little skate tool bag. Madness…

It got ugly. The inserts I used previously had a small lip, so used a dremel to cut small groves in the lip and then hammered finishing nails into the groves to lock the insert in place and unscrewed the screw. Then I filled nail holes in with jb weld hoping it would hold the insert in place, which it did. Been using jb weld on all my inserts ever since.

Material compatibility: One of the most important factors to consider when choosing grooving inserts is the material you will be cutting. Different materials have different properties, such as hardness, toughness, and abrasiveness, which can affect the performance of the insert. For example, if you are cutting a hard material like stainless steel, you will need a grooving insert with a high wear resistance and toughness to withstand the cutting forces. On the other hand, if you are cutting a softer material like aluminum, you may need a grooving insert with a sharper cutting edge for better chip control.

Now these 8-32 screws enter my life lol. I bought 8-32 torx head screws, and was intending to add epoxy to the loose inserts. But now one of these inserts is damaged, and with all the trouble already, I’m tempted to move up to M4 or 10-32.

The threaded insert is spinning in the wood. Either it’s not threaded on the outside, or the wood’s all toast and it’s spinning. Pushing on it from the top while unscrewing isn’t doing the trick. At least not with hand pressure. Might try with a clamp if I can find something hollow. Or maybe not even hollow…

This is actually quite a puzzle for me. We’re cursed with both metric and imperial, cursing the rest of the planet too, with #10-32 skateboard hardware.

slam it with a hammer till it comes out then just fill the hole with some wood resin mix or something or loose your nerves trying to get it out

Something is messed up, If you drill in to the bottom of the screw (center) with a regular drill bit in forwards, won’t that be like using a screw extractor except you will also be pushing the screw and thread out? Either one or both parts will come out then you can epoxy in a replacement…

Had this happen to me before, sucks. Now I use these inserts and dab some jb weld on the inserts before I screw them in…no issues at all.

On the top side, the insert is below the surface and the screw sticks out past the insert, so I can’t do any tricks with a screw on the top side.

I’ve got a threaded insert that’s spinning in the wood, can’t get the screw out. I think the insert might not be threaded on the outside, because it doesn’t back out when it spins. I didn’t install it, so I don’t know exactly what’s going on.

Chip control: Effective chip control is essential for achieving a smooth surface finish and preventing chip jamming during cutting operations. Grooving inserts with the right chip breaker design can help improve chip control and reduce the risk of tool breakage. Consider the type of chip control you need for your specific application, whether it is continuous chips, segmented chips, or curled chips, and choose an insert with the appropriate chip breaker geometry.

Holy cow thanks guys. I got it. I found a t-nut that kind of fit on top of it, and used a c-clamp. It wouldn’t hold because the angles are all wrong, but added just enough pressure to back the screw out.

Tool holder compatibility: Before selecting a grooving insert, make sure it is compatible with your tool holder. Different tool holders have different clamping mechanisms and insert geometries, so it is important to choose an insert that fits securely in your tool holder to prevent vibration and tool runout. Check the manufacturer's specifications to ensure compatibility between the insert and tool holder.

https://www.amazon.com/uxcell-M5x10mm-Socket-Thread-Insert/dp/B01AXY9AQW/ref=pd_day0_hl_60_5?_encoding=UTF8&pd_rd_i=B01AXY9AQW&pd_rd_r=c3a2d809-99cb-11e8-8719-f5a2c5be41ea&pd_rd_w=FZ7hW&pd_rd_wg=Kfd6B&pf_rd_i=desktop-dp-sims&pf_rd_m=ATVPDKIKX0DER&pf_rd_p=1675207170591242776&pf_rd_r=P3Z8DEB6XY1YE162Y43N&pf_rd_s=desktop-dp-sims&pf_rd_t=40701&psc=1&refRID=P3Z8DEB6XY1YE162Y43N

Cutting conditions: The cutting conditions, such as cutting speed, feed rate, and depth of cut, also play a crucial role in selecting the right grooving insert. Different inserts are designed to perform optimally under specific cutting conditions. For example, if you are cutting at high speeds, you will need a grooving insert with a high heat resistance to prevent thermal cracking. Similarly, if you are using a high feed rate, you will need an insert with a strong cutting edge to withstand the increased cutting forces.

Budget considerations: While it is important to choose a high-quality grooving insert that meets your cutting requirements, it is also essential to consider your budget constraints. There are various options available at different price points, so it is important to strike a balance between cost and performance. Consider the overall cost of the insert, including the initial purchase price and the cost per cutting edge, to determine the best value for your cutting needs.

0086-813-8127573

0086-813-8127573