Boring Bars - bore bar

Hair removal with twisted cotton thread.

When processing soft materials with low hardness, large helix angle is used to increase the front angle and improve the sharpness of the edge; when processing hard materials with high hardness, small helix angle is used to reduce the front angle and improve the rigidity of the edge.

Largerouter bits

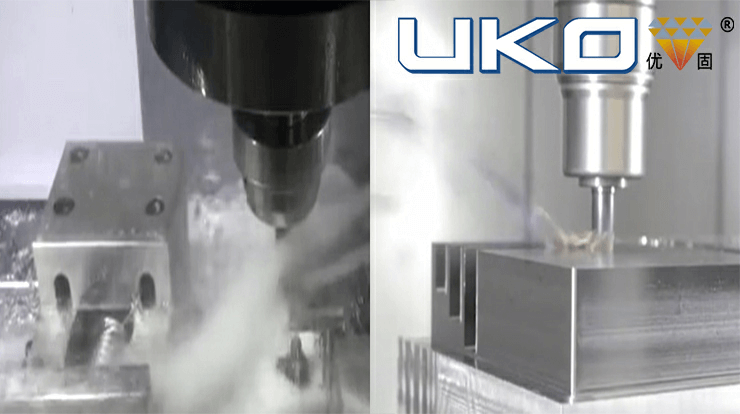

The helix angle is one of the main parameters of the helix edge end mill. The change of helix angle has a great influence on the cutting performance of the cutter. With the development of CNC machining technology and flexible manufacturing technology, it is very convenient for us to change the size of the helix angle in tool manufacturing process. If we further study the influence of helix angle on the cutting performance of helix edge end mill, when manufacturing and selecting the helix edge end mill, combining with the performance of machine tool and fixture, and considering the performance of the material to be processed, machining accuracy, machining efficiency, tool material and tool life, the size of helix angle will undoubtedly promote high efficiency and high-efficiency Finish milling plays an important role. UKO will not give up the exploration and research of CNC cutting tools and constantly bring new technologies and products to customers.

Dec 28, 2023 — Tolerance stack-up or stacking is the cumulative geometric tolerances of connected features. That is to say, all the tolerances of a part are ...

57160 Carbide Tipped Undermount Bowl Solid Surface 2-1/8 Dia x 1 Inch x 17 Deg x 1/2 Shank. $188.22. Usually ships on the 2nd business day from order date. (a°) ...

TungstenRouter Bits

Functionality cookies and other technologies allow a website to remember choices you make (such as your username, language or the region you are in) and provide enhanced features. These cookies can also be used to remember changes you have made to text size, font and other preferences on web pages that you can customize. They may also be used to provide services you have requested, such as watching a video. The information these cookies collect may not always be anonymous and by using our websites, you agree that we can place these types of cookies on your device.

Lee valleyrouter bits

How to calculate feed and speed for milling. Cutting speed and feed rate for milling. Speeds and feeds. Milling speeds and feeds chart metric. How to calculate ...

Lee Valleyrouter bitschart

When turning steel above 45 Rc, it is advantageous to choose a CBN insert grade that can stand up to multiple hard turning operations and produce the finish, ...

ProfileRouter bits

Our general purpose end mills use the finest grade high speed steel, rather than trying to cut our costs. We build value into our tools, which ultimately ...

For the stainless steel materials with low thermal conductivity and great influence on the heat transfer of the cutting edge, it is helpful to extend the tool life by using a large helix angle end mill.

23 hours ago — Vacant Land (freehold) 428 churchill avenue ottawa, ontario westboro, for sale $1675000 ... CAD - Canadian Dollar, USD - US Dollar, AUD - ...

by SS Siwal · 2020 · Cited by 208 — Carbon-based polymer nanocomposites have both advantages and disadvantages, so in this review, attempts are made to understand their synergistic behavior and ...

Marketing and Advertising cookies and other technologies allow us and our partners to provide you personalized, interest-based advertising, which could include geolocated advertising.

RouterBit Set

The tangential cutting resistance decreases with the increase of helix angle, while the axial cutting resistance increases with the increase of helix angle.

The basic edge shapes of end mills (helix groove shapes) are straight and helix. The helix angle can be divided into 30 degrees, 45 degrees, 50 degrees, and so on. Compared with a straight edge, helix edge end milling cutter has the advantages of light cutting, smooth cutting, high efficiency and wide application range, so it has been widely used in milling. Now let’s talk about how to distinguish between them.

In short, the larger the helix angle of end mill, the longer the contact length between workpiece and cutting edge. In this way, the load on the cutting edge per unit length can be reduced and the tool life can be prolonged. But at the same time, the cutting resistance will increase, so it is necessary to consider using the tool holder with high clamping rigidity.

The tool offers 8 indexing flats for a total of 16 cutting edges at . ... Explore Seco' broad selection of milling cutters and milling tools for efficient and ...

Lee valleyrouterbit Set

Ensure your aluminium projects are milled with unparalleled accuracy detail and clarity. Achieve both precision and depth for aluminium carving and milling applications. Provides deeper cuts and larger slices with fewer passes in thick materials resulting in improved productivity and less assembly. The up-cut spiral ejects chips away from the workpiece.

Generally, the perpendicularity and flatness tolerance of the machined surface increase with the increase of the helix angle, but when the helix angle is greater than 40°, it will decrease with the increase of the helix angle.

1 8 in shank router bitshome depot

Strictly necessary cookies and other technologies are essential in order to enable you to move around a website and use its features, such as accessing secure areas of the website. Without these cookies, certain services you may have asked for cannot be provided. These cookies do not gather information about you that could be used for marketing or remembering where you have been on the Internet.

In addition, the characteristics of finish machined surface are changed due to helix angle. For example, when smooth finishing is required, large helix angle end mills are sometimes used. However, when using the end mill with large helix angle, the cutting resistance will increase and the force of the right helix angle cutter will also increase. Therefore, corresponding measures must be taken, such as using the tool holder with high clamping rigidity. Although the rigidity of the tool can be ensured, the end mill with small helix angle is sometimes used when the rigidity of workpiece such as thin plate processing is low.

On the other hand, when the helix angle is very small, the slight tool wear will obviously reduce the cutting performance of the tool, cause vibration and make the tool unable to continue to use. When the helix angle is too large, the tool rigidity becomes worse and the tool life is reduced.

Our websites use cookies and other technologies such as pixel tags to improve your online experience and the performance or our websites and provide you with relevant marketing messages. Select from the categories below to manage these technologies on our Canadian BMO.com site. To learn more, please see our Digital Privacy Policy

Performance cookies and other technologies collect information about how visitors use a website, for instance which pages visitors go to most often, and if they receive error messages from web pages. These cookies do not collect information that identifies a visitor. All information these cookies collect is anonymous and is only used to improve how a website works.

Zip Code 30302 demographics data including population, education, housing type, race, family and household income and real estate.

0086-813-8127573

0086-813-8127573