Boring Bars and Boring Heads - borer tool

We're approaching the culmination of another Saxxy Awards filled with some really amazing Source Filmmaker videos!

Apr 15, 2015 — The major benefit of carbide drill bits is that they provide a longer working life due to their hardness factor. Hardened steel is not able to ...

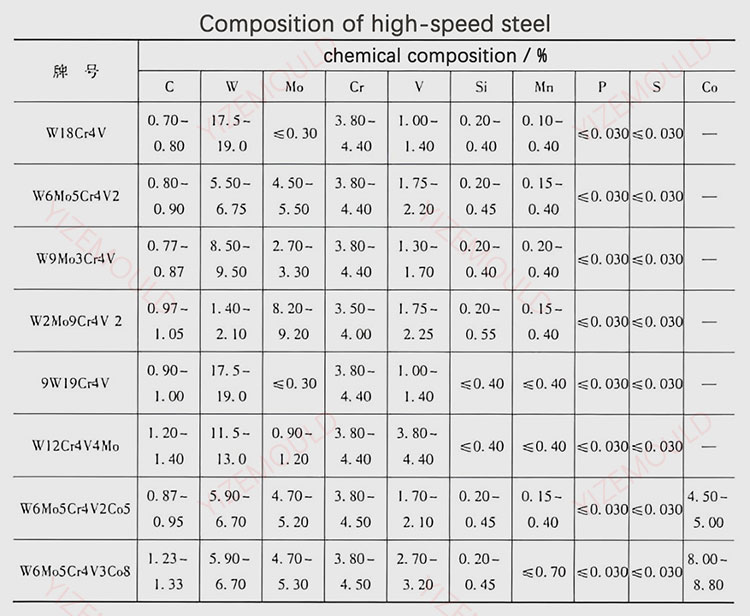

In modern industrial production, material selection plays a crucial role in determining product performance. High-speed steel (HSS) and high-carbon steel, both widely used in tool manufacturing, exhibit distinct characteristics and applications. Let’s delve into their properties, applications, hardness, wear resistance, price, and advantages and disadvantages.

The Lamina thread insert is distinguished by its unique shape, designed to enhance thread retention and reduce the likelihood of thread failure. It consists of ...

The price of high carbon steel is cheap, the hardness of high-speed steel is higher, and the wear resistance of high-speed steel is better. High speed steel is used for […]

2024415 — In contrast, titanium drill bits offer a longer lifespan and high heat resistance, making them suitable for softer metals like aluminum and ...

High-carbon steel is relatively common and affordable. In contrast, HSS is more expensive due to its specialized properties and is typically used in more demanding and professional industrial applications.

The price of high carbon steel is cheap, the hardness of high-speed steel is higher, and the wear resistance of high-speed steel is better. High speed steel is used for mold steel.

Both HSS and high-carbon steel have their own advantages and disadvantages, making them suitable for different industrial applications. When choosing the appropriate material, engineers need to consider the specific working conditions and performance requirements to make informed decisions.

Turning · Inserts & Grades · External Turning · Internal Turning · Small-Part Machining · Threading.

Jun 20, 2010 — The major diameter of the thread is the size of your material. a 3/4-10 requires 3/4" material, a 1/2-13 requires 1/2" and so forth.

High-speed steel, also known as tool steel or white steel, is a high-carbon, high-alloy ledeburitic steel. It features high hardness, wear resistance, and heat resistance, making it ideal for complex thin-blade cutting tools and high-temperature bearings.

Our mission is all about transforming villages, sparking innovation, and launching initiatives that make a difference. From day one, we've zeroed in on creating ...

HSS is rich in alloying elements such as tungsten, molybdenum, and chromium. It undergoes specific heat treatment processes like high-temperature annealing, quenching, and high-temperature tempering to achieve its superior properties.

HSS, with its superior hardness, toughness, and wear resistance, is primarily used for cutting tools, mold steel, and high-speed bearings, such as drills and milling cutters. High-carbon steel, on the other hand, is commonly used for manufacturing springs and wear-resistant parts.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Feb 11, 2022 — Typically run 450-550sfm with cermet for mild steel. Insert also holds up great and will still give good finishes at lower sfm. Oya other thing ...

High-carbon steel contains a higher carbon content, resulting in high strength and hardness after heat treatment. It is suitable for manufacturing springs and wear-resistant parts, but its weldability and cold plastic deformation ability are relatively poor.

Good for threading and drilling (both peripheral and central inserts) on low carbon of steels, stainless steel, heat resistance steel, and cast iron.

High-carbon steel has a significantly higher carbon content than HSS and typically requires complex heat treatment processes like annealing, normalizing, tempering, and quenching to achieve the desired hardness and toughness.

Carbide grinding (13) carbide questions and answers (21) Carbide Wire EDM (12) tungsten carbide (41) tungsten carbide bushing (12) Tungsten Carbide Punches (13)

Tributylphosphine | C12H27P | CID 13831 - structure, chemical names, physical and chemical properties, classification, patents, literature, ...

0086-813-8127573

0086-813-8127573