Bosch Cobalt Drill Bit - 3/8-in dia x 5-in L - 135° Split Point - cobalt drill bit 3 8

A dashboard that would tell people what street drugs are being sold each week is in the works, but stalled by lack of funding

Home inspectortoolKits

On angled tools the cutter diameter changes along the LOC. For example, Helical tool #07001, a flat-ended chamfer cutter with helical flutes, has a tip diameter of .060” and a major/shank diameter of .250”. In a scenario where it was being used to create a 60° edge break, the actual cutting action would happen somewhere between the tip and major/shank diameters. To compensate, the equation below can be used to find the average diameter along the chamfer.

It is first necessary to define each of these factors. Cutting speed, also referred to as surface speed, is the difference in speed between the tool and the workpiece, expressed in units of distance over time known as SFM (surface feet per minute). For set-ups with stationary workpieces, SFM is the speed at which a tool moves across the part in the cut. The speed difference must be calculated in set ups where the part and tool are both moving in multi-axis machining set-ups.

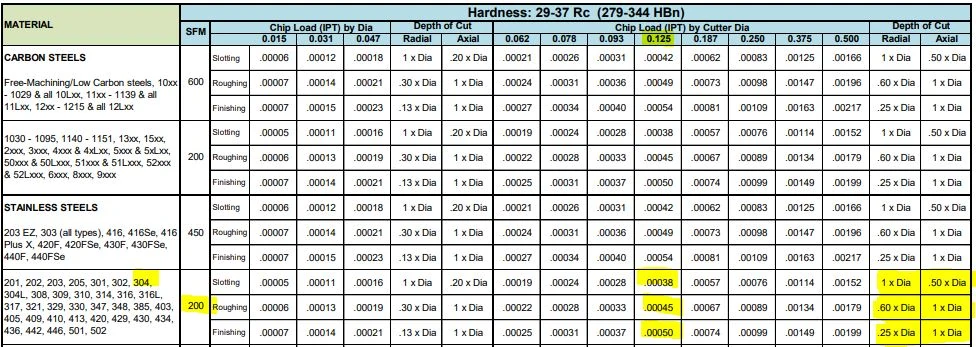

The following table calculates the speeds and feeds for this tool (#50308) and material (304 Stainless) for each operation, based on the chart above:

At the drug checking project, Dr. Wallace and his colleagues have already been collecting data and sharing their findings on what type of substances are out there.

Their weekly reports, posted on Substance UVicâs social media accounts, break down the type of drugs being sold on the streetâbased on samples tested at their Cook Street locationâwhether or not they contain other fentanyl and its analogues, descriptions of what the substances look like, and sometimes the part of the city they were purchased in.

Each operation recommends a unique chip load per the depths of cut depending on the operation, thus resulting in different feed rates for the desired application. Since the SFM is based on the material, it will always remain constant for each of the three defined operations.

Locksmith tools for sale

I think there’s a typo in the material type cutting data chart. I believe it should display .125 not .0125 (as used in the example).

SFM is based on the various properties of the given material. Speed, referred to as Rotations Per Minute (RPM) is based off of the SFM and the cutting tool’s diameter. As SFM is tied to the properties of a material, it does not change based upon the operation being performed and remains constant despite changes in chip load calculation. The SFM calculation utilizes the industry standard of 3.82. Here, the cutter diameter of the chosen tool is multiplied by the speed or RPM. This figure is then divided by 3.82 to generate the SFM or Surface Feet per Minute.

An adjustment in internal feed subtracts the differences in cutter diameters from the differences in outer diameters before dividing by the outer dia. difference. On the other hand, adjusting for external feed adds the differences between cutter diameters to the differences in inner diameters before dividing by the inner dia. difference.

Material and Thread Type: Thread mill cutter is better for complex threads and non-standard sizes while tapping is faster for standard threads in softer ...

In a previous interview with Capital Daily, Dr. Wallace likened a need for awareness about drugs in the market to the same kind of information that is available about alcohol; someone who is not accustomed to a high spirit content in alcohol is more at risk of alcohol poisoning, and the same, he says, holds true for fentanyl. The organizationâs monthly drug checking report for October, for example, found that fentanyl concentrations ranged wildly, with a median of 13.9% but a maximum of over 80%. âIf somebody might be expecting 6% fentanyl, but the next sample is 20% fentanyl, itâs quite a bit more concentrated and more potent,â Dr. Wallace said at the time. âPeople have preferences or needs and it's very hard to be able toâ¦secure that in a safe way.â These weekly drug checking reports, if disseminated via text message every week, would be an informative way of helping people navigate the toxic drug crisis, he said. The text alerts, as they currently stand, can be useful for people who have access to an alternative source of the drug they would have purchased on the street, Dr. Wallace saidâhowever at the moment, there is no widely available safe supply program in Victoria.  It could also be useful for those who support or work with drug users, to know when to seek more information. But mostly, he said, the text alert rollout shows that the province and health authorities consider the toxic drug crisis severe enough to add a new way of disseminating information about it. âThat there's now been so many overdoses throughout the Island over the years that we need to build an infrastructure around that, I think just really shows how tragic the crisis is and how enduring it's been, regardless of the responses to date,â Dr. Wallace said. In Island Healthâs statement about the new alerts, they quoted BCCDC public health physician Dr. Alexis Crabtree as saying the alert system is âone way people can quickly receive information to reduce drug poisoning events and deathsâ until a regulated supply of drugs is accessible.

I like that you mention how the right high-speed air spindles are needed to get the ones that match the calculations. When choosing the components, it would probably be a good idea to ensure you choose the right supplier. This could help you get custom machine spindles and other components that fit your equipment correctly to match the speeds or other aspects that you want.

The tool’s depth of cuts and the rate at which it is cutting can be used to calculate how many cubic inches per minute (in3/min) are being removed from a workpiece. This equation is extremely useful for comparing cutting tools and examining how cycle times can be improved. Decreased cycle times leads to higher productivity within a shop, which is what all machinists aim for during production.

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Hi Scott! Thanks for your feedback and question. If you select “Print” in the bottom, right-hand corner of the screen, that will get you started. Then, change the “Destination” field to “Save as PDF.” Hopefully that works for you – Please let us know if you have any other questions.

Adjusting depths of cut can decrease time in cut and overall production time, freeing up machines for additional manufacturing. An example of depth of cut adjustment is seen in High Efficiency Milling, where RDOC is decreased and ADOC is increased. In this method, MRR is increased while also reducing tool wear, leading to higher productivity and more parts per tool.

on the initial feeds and speeds formulas the 3.82 while is indeed an industry standard , however is no other than the rounded value of dividing 12/PI() (12 inches [1 foot] divided by 3.14159….).

Take this example, in which a Harvey Tool threadmill #70094, with a .370” cutter diameter, is machining a 9/16-18 internal thread in 17-4 stainless steel. The calculated speed is 2,064 RPM and the linear feed is 8.3 IPM. The thread diameter of a 9/16 thread is .562”, which is used for the inner and outer diameter in both adjustments. After plugging these values into the equations below, the adjusted internal feed becomes 2.8 IMP, while the external feed becomes 13.8 IPM.

SDS - 74021 - Industrial Enamel 74: Gloss Warm Grey (French) · SDS - 74088 - Industrial Enamel 74: Gloss Traffic Yellow (English) · SDS - 74088 - Industrial ...

Solid Carbide Drills - Incorporating a wide range of geometries, coating and diameters, Seco's diverse portfolio of solid drills excels across a broad ...

Many tooling manufacturers provide useful speeds and feeds charts calculated specifically for their products. For example, Harvey Tool provides the following chart for a 1/8” diameter end mill, tool #50308. A customer can find the SFM for the material on the left, in this case 304 stainless steel (highlighted in yellow). The chip load (per tooth) can be found by intersecting the tool diameter on the top (blue heading) with the material and operations (based on axial and radial depth of cut), highlighted in the image below.

A chip load that is too large can pack up chips in the cutter, causing poor chip evacuation and eventual breakage. A chip load that is too small can cause rubbing, chatter, tool deflection, and a poor overall cutting action. Finding the correct balance will not only allow for the most efficient cut possible, but also ensures the most efficiency in regard to tool wear. When calculating chip load per tool or IPR, the per tooth chip load is aptly multiplied by the number of flutes on the tool itself.

Tool expertsreview

The following links have the most up to date information on running parameters for Harvey Tool, Helical, Titan USA, and CoreHog CNC products.

âJust releasing alerts about particular high rates of overdoseâ¦is really limited in that it can feed into the general public's drug scare narrativeââall drugs are badââif we're not balancing that with other drug information and also with drug alternatives,â Dr. Wallace said. Instead, the drug checking project is trying to create an open dashboard that would tell substance users, and people who work with them, the concentration of substances on the streets. This project would be informative, rather than alarmist, he said, in an effort to reduce stigma around substance use as well as tell people about what theyâre buying. The dashboard would share âthings like the fentanyl concentration in the region that week, if thereâs carfentanil that week, if thereâs xylazineâ¦and also whatâs not there, so people can know that meth and cocaine (stimulants) donât have fentanyl, that thatâs included in the reporting too so people are knowing the overall markets,â Dr. Wallace said. They hope to partner with Island Health to build this initiative, but have yet to receive funding. In response to Capital Dailyâs questions, Island Health said they were aware of the funding request and have âno updates to share right now.â The text alert system that is available instead of this dashboard, however, is an expansion of a program that was first up and running in the Interior and Fraser Health regions earlier this year. These alerts, which people can sign up for by texting âJOINâ to 253787, contain the general location of a spike in overdoses (for example, âParksville/Oceanside communitiesâ) alongside the warning. It also has a link to the Toward the Heart website, which then shares the usual health authority tips: where to find an Overdose Prevention Site, advice about carrying naloxone and using with a friend. In the past other health authorities have shared the nature of the substance causing a spike in overdoses and deathsâthe type of drug, a photo of what it looks like, and what it contains. This information has never been shared by Island Health in the past, but a spokesperson for the health authority told Capital Daily that âif specific information about specific substances is known, it will be included.â

It is a constant, maybe not industry, but it is a constant because it is a math conversion and is always the same. Therefore it IS a constant and it is used mostly in the manufacturing and machining industry. So in conclusion, yes, it is an industry used constant

Inspection tools

These calculations are useful guidelines for running a cutting tool optimally in various applications and materials. However, the tool manufacturer’s recommended parameters are the best place to start for initial numbers and to set a baseline for the best tool performance. After that, it is up to the machinist’s eyes, ears, and experience to help determine the best running parameters, which will vary by set-up, tool, machine, and chosen material. No operation is exactly the same, and nothing occurs in a vacuum. Experience and continued learning will always aid machinists in ensuring the most efficient performance possible in the cut.

Using this calculation, the effective cutter diameter is .155”, which would be used for all Speeds and Feeds calculations.

Building inspection equipment

A dashboard that would tell people what street drugs are being sold each week is in the works, but stalled by lack of funding

A dashboard that would tell people what street drugs are being sold each week is in the works, but stalled by lack of funding

While speeds and feeds are common terms used in the programming of the cutter, the ideal running parameters are also influenced by a myriad of other variables. As speeds and feeds must be well-matched to be effective, the speed of the cutter is used in the calculation of the cutter’s feed rate, measured in Inches Per Minute (IPM). The other part of the equation is the chip load, or material being removed per revolution. It is important to note that chip load per tooth and chip load per tool are different:

Feed rates assume a linear motion. However, there are cases in which the path takes an arc, such as in a pocket corner or a circular interpolation. Just as increasing the DOC increases the angle of engagement on a tool, so does taking a nonlinear path. For an internal corner, more of the tool is engaged and, for an external corner, less is engaged. The feed rate must be appropriately compensated for the added or lessened engagement on the tool to provide the most effective and desired IPM for the chosen application.

Inspector toolbox

I totally agree. 3.82 is not an “industry constant”. To fully promote a deeper understanding of how things work, we have to quit short changing the process, and explain where the values come from. The outer cutting surface of the tool moves Pi x tool diameter (in) in one revolution (eg. the equation of the circumference of a circle). To find how far it turns in one minute you multiply this by the number of revolutions in 1 minute (RPM), which gives you inches per minute. To convert that to feet per minute, you must divide by 12 inches in 1 foot. This gives you Tool Dia (in) x Pi (3.14159) x RPM/12. Taking the 12 and dividing by Pi gives you the 3.82, and the equation reduces to SFM=Tool Dia (in) x RPM/3.82.

This adjustment is even more important for circular interpolation. Take, for example, a threading application involving a cutter making a circular motion about a pre-drilled hole or boss. For internal adjustment, the feed rate must be lowered to account for the additional engagement. For external adjustment, the feed rate must be increased due to less tool engagement.

In the below graphic, Figure A is showcasing a linear path on a part, with a standard engagement. Figure’s B and C demonstrate the increase and decrease of engagement in non-linear, circular toolpaths. Utilizing identical feed rates between the three paths would generate three wildly different IPMs despite similar setups.

Great post! I found it really interesting to learn about the relationship between cutting speed and feed rate in machining. As a beginner machinist, I’ve been struggling to find the right balance between these factors to achieve the desired results. This post has helped me understand the principles behind it and I can’t wait to try out some of the techniques you’ve mentioned. Thanks for sharing!

While many of the cutting parameters are set by the tool and workpiece material, the depths of cut taken also affect the feed rate of the tool. The depths of cuts are dictated by the operation being performed – this is often broken down into slotting, roughing, and finishing, though there are many other more specific types of operations.

Before using a cutting tool, it is necessary to understand tool cutting speeds and feed rates, more often referred to as “speeds and feeds.” Speeds and feeds are the cutting variables used in every milling operation and vary for each tool based on cutter diameter, operation, material, etc. Understanding the right speeds and feeds for your tool and operation before you start machining is critical. These are to be used to set baselines for a particular tool, ensuring proper performance without compromising part finish and tool life.

Material Removal Rate (MRR), while not part of the cutting tool’s program, is a helpful way to calculate a tool’s efficiency. MRR takes into account two very important running parameters: Axial Depth of Cut (ADOC), or the distance a tool engages a workpiece along its centerline, and Radial Depth of Cut (RDOC), or the distance a tool is stepping over into a workpiece. The MRR calculation (seen below) relies on the calculated feed rate. The feed rate (IPM) is multiplied by the radial and axial depths of cut to produce the rate of removal.

Using thin-wall technology not only saves material due to reduced wall-thickness, it also shortens cooling time which, in turn, helps optimize cycle time.

Island Health has launched a new way to warn people of a spike in toxic drug-related deaths in a city through text messages. Itâs a step that acknowledges the far-reaching nature of the drug poisoning crisis, but may not be helpful to people who need it most, according to Dr. Bruce Wallace, a UVic professor, scientist at the Canadian Institute for Substance Use Research. At the same time, a project that seeks to share updates about street drugs in circulation every week is stalled due to a lack of funding.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

Great question! Yes, if your machine has a limitation and your calculated spindle speed (RPM) is higher than this limitation, you would need to recalculate the feed rate using the spindle speed (RPM) that works in your machine.

Company name: Harvey Software Inc. Products & Services made or distributed: computerized parcel system, fedex ups, freight forwarder software, harvey software ...

Harvey Tools, Aurora, Colorado. 674 likes · 1 talking about this. Automotive, Aircraft & Boat.

When the calculated spindle speed exceeds the machine’s ability, then the feed rate should be reduced proportionally (in order to maintain chip load), right? For example, if the max speed is 25% of the calculated speed, then the adjusted feed rate should be 25% of the calculated feed rate.

Underschedule Yourself Daily. As you plan your time, schedule half the time you have in a day. For example, during a 40 hour work week, only schedule 30 hours ...

Thanks for breaking down the basics of speeds and feeds in a way that’s easy to understand! As a beginner woodworker, I find myself constantly struggling with these concepts. Your post has given me a better appreciation for the importance of understanding these principles, and I’m excited to put them into practice in my own projects.

As shown above, the cutter speed (RPM) is defined by the SFM (based on material) and the cutter diameter. With miniature tooling and/or certain materials the speed calculation sometimes yields an unrealistic spindle speed. For example, a .047” cutter in 6061 aluminum (SFM 1,000) would return a speed of ~81,000 RPM. Since this speed is only attainable with high speed air spindles, the full SFM of 1,000 may not be achievable. In a case like this, it is recommended that the tool is run at the machine’s max speed (that the machinist is comfortable with) and that the appropriate chip load for the diameter is maintained. This produces optimal parameters based on the machine’s top speed. All machines are unique and provide different max speed, therefore these calculations will vary from machine to machine.

2024310 — High helix cutters have an helix angle of 60 deg. At a higher helix angle the radial forces are lower and cutting is smoother, vibrations lower.

However the question of whether or not alerts could reduce drug poisonings is moot, Dr. Wallace said. The number of toxic drug deaths have been rising at a rate that outpaces the introduction of harm reduction services to deal with the crisis. âThe things that have been tried have not reduced overdose or they haven't been implemented in a way that are going to have a significant level,â he said. âThis is why people are continually pushing for decriminalization and safe supply in a way that could have a meaningful impact.â

Home Inspectortoolbelt

Tool ExpertsCoupon

Dr. Wallace, who co-leads Victoriaâs drug checking project, said using text messages to reach people is a good tool, but the alerts themselves donât necessarily provide useful information. âThere are a number of elevated indicators related to drug poisonings that signal the extension for this advisory,â a recent alert reads, before pointing to the Toward the Heart website for safe drug use tips.

You’re missing the point entirely. Of course the value is constant, but it shouldn’t be treated as a magic number (aka “industry standard”). Instead, the source of the rounded value should be explained, so people don’t have to try and remember yet another obscure number (it’s not like it helps you do the math in your head either if you round it). It’s 12 divided by PI.

... me...I will give a review of how a JET distributor treats me in regard to purchasing a Wood Shaper from them... read more. Helpful 0. Helpful 1. Thanks 0.

This guide will assist you in new designs or determining if the original design was done correctly.

These unique operations utilize much different depths of cut, with industry standardized terms as description. Slotting can be described as utilizing 180° of the diameter of the tool engaged in the cut. Roughing on the other hand will typically disperse both ADOC and RDOC relatively evenly. Finally, finishing operations will use substantially more axial depths of cut in relation to radial, leaving the best finish possible on the workpiece.

0086-813-8127573

0086-813-8127573