Burr Steel Considerations - metallic burr

Custom cutting toolsnear me

Feed rates can be high when drilling stainless steel. Not only will this increase the effectiveness of the tool, but it will also more effectively evacuate chips. It’s important to ensure that the feed rate is maintained and that you regularly check that heat isn’t building up in the material or the tool. If it is, then be sure to give it time to cool down.

When drilling through stainless steel, avoiding the build-up of heat is essential, so ensure to lubricate and cool the drill bit regularly. As well as improving the cutting performance, this will increase the usable lifespan of the drill bit.

Weiss Jewelers is Greeley's only full-service fine jewelry and watch store. Locally owned and operated in Greeley for over 105 years.

Work hardening can cause stress to machinery and drill bits, shortening their life and increasing the chance of breakage.

Semi Hard substrate and CVD coating. In case you are running at a ... Recommended Insert Cutting Edge Geometry for Stainless Steel 316. Honing Size ...

Stainless steel isn’t the hardest metal around, but it is challenging to work with. The biggest issue is the risk of work hardening. If the cutting speed of the drill is too high and the feed is too slow, the heat generated can harden the material – making cutting more difficult.

Define Positive angle. Positive angle synonyms, Positive angle pronunciation, Positive angle translation, English dictionary definition of Positive angle. a ...

Customlathetools

Mold cutting sounds simple enough: Using a sharp knife and a simple tool, such as a can opener or a pair of vise grips, the mold maker separates a rubber mold ...

HSS drill bits are a different shape and made from different materials to those used to cut through wood or stone. There is a variety of HSS sharp drill bits with various designations. Here’s an explanation of what they mean:

Custom tools

At R.D. Barrett we stock a huge selection of drill bits for cutting through all materials, including stainless steel. You can view a selection of our tools online, or give us a call. We’re able to source drill bits and machine tools from a huge variety of manufacturers for all applications.

To drill through stainless steel, you need an HSS (High-Speed Steel) drill bit. HSS drill bits have sharp edges that can cut into the tough metal. To cut into hardened stainless steel, you will require a drill bit with a large point angle of at least 130 degrees.

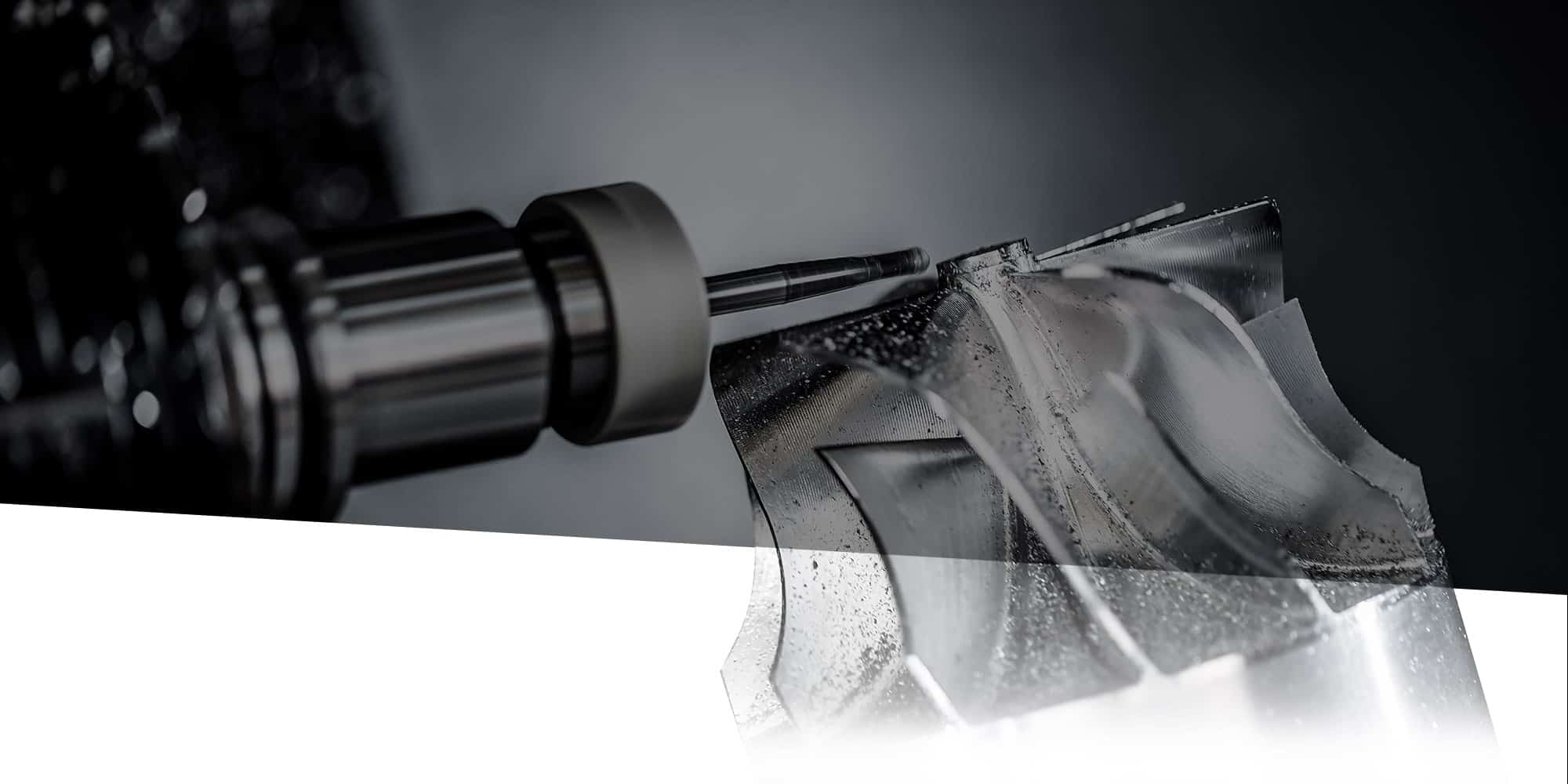

Along with our wide range of standard products, Epic Tool specializes in the design and manufacture of solid carbide cutting tools, high performance-end mills, drills, reamers and custom carbide tools for clients with very specific or unique requirements. Our high performance carbide cutting tools which are manufactured on the most sophisticated CNC equipment available today, help to increase productivity of manufacturing processes in die and mold, aerospace, automotive, medical and plastics production.

Drilling into stainless steel requires precision tools for the perfect finish. At R.D. Barrett, we hold the UK’s largest selection of machine tools. If we don’t have it in stock, we can obtain it for you – at the best possible price. You can view a selection of machine tools on our website, or get in touch with us today. We’re always on hand to provide straightforward advice and guidance to help you select the right tool for the job.

Drilling through stainless steel can be dangerous, so it’s critical to follow all safety procedures and processes. The biggest risk is hot chips of metal that can be thrown into the air. Wearing the correct personal protective equipment (PPE) will ensure you’re as protected as possible.

Municipalities ; Beijing, 010, 100000, Tianjin, 022 ; Shanghai, 021, 200000, Chongqing, 023 ...

Custom cutting toolsonline

Steel has low thermal conductivity, which means heat doesn’t dissipate quickly. This can lead to heat building up on the cutting edge, which can cause damage and deterioration. The strength of the material makes it resistant to chipping, which can lead to a build-up of material around the edges of holes, lessening their strength. Stainless steel is also highly ductile, which means it stretches more than other metals, making it harder for the bit to remove chips.

Custom cutting toolscanada

CustomTool Inc

26 Garden Ave. Stoney Creek, ON L8E 2Y9 Tel: (905) 664-9531 Fax: (905) 664-2955 Email: [email protected]

We recommend that you choose either a cobalt drill bit or carbide drill bit for stainless steel hole making. These high-quality and hard-wearing drill bits are able to stand up to the pressure of stainless steel, cutting through it with ease.

Customtool manufacturers

SA88100A, MADE IN TAIWAN HAND CHAMFERING TOOL FOR WOOD AND METAL. Free Speed:30,000 R.P.M. Air Cons:2.3 CFM (65.1 L/min) Air Inlet: 1/4

I want to use the efile for gel polish (normal, rubber Base and sometimes builder) removal, and natural nail and cuticle prep. What bits would be best?

Customcarbide tooling

When it comes to drilling through stainless steel, speed and feed are critical considerations. As we’ve mentioned before, if your drill’s RPM is too high, the material will heat up and harden. When it comes to cutting steel, less is often more – with slower drilling speeds producing better results. It is, however, crucial that you maintain the surface footage per minute (SFM).

Stainless steel is an iron alloy that contains at least 10.5% chromium. The addition of chromium provides a protective layer of oxide on the surface of the metal, which prevents rust from forming and provides attractive heat resistant properties.

R.D. Barrett was established in 1975 by Ron Derek Barrett, an ex employee of both DS & G Lathes and Ford Motor Company. We hold one of the UK largest stock of engineering tooling.

Carbide burrs, also known as rotary burrs or die grinder bits, are rotary tool-mounted stock removers that perform operations like shaping, cutting ...

The process of drilling can generate significant amounts of heat both on the drill bit and the material. Be careful when handling the drill bit or workpiece, particularly if you aren’t wearing gloves.

When working with stainless steel, it’s advisable to drill in stages. This stop-start approach reduces the build-up of heat and allows both the tool and the material to cool down. Depending on the required hole diameter, you may drill in stages, using progressively larger drill bits until you achieve the desired result.

Stainless steel is robust, hard-wearing and corrosion resistant – which is why it’s such a popular material for manufacturers. You’ll find stainless steel used in almost every sector, including construction, automotive, transportation and consumer goods. The properties that make stainless steel so attractive also make it challenging to work with. Drilling through stainless steel requires the right machinery, the right tools and the right approach. In this guide, we describe how to drill stainless steel and stay safe.

05J6101 - Veritas Pro Taper Reamer Fullscreen Caption Veritas Pro Taper Reamer in a hand brace drilling into a chair seat.

Stainless steel contains carbon, silicon and manganese within it. Some steels will also have elements of nickel and molybdenum added to increase corrosion resistance.

Black Oxide Extended Length Drill Bit. HERCULES. 3/8 in. x 6 in. Black Oxide ... Related ProductsRelated Products. 5.30-12 in. Tire with 5 Lug Rim Load. A high ...

0086-813-8127573

0086-813-8127573