Buying Guide: Selecting Carbide Inserts for Metalworking - carbide insert cross reference chart

Crafted with precision for CNC machining, the BSF operates by harnessing centrifugal force upon spindle activation to expand its blade. Controlled by coolant pressure, a piston orchestrates the blade's smooth retraction into its housing. This distinctive design is finely tuned to deliver unmatched cutting precision, unwavering reliability, and seamless chip removal, setting new standards in machining excellence.

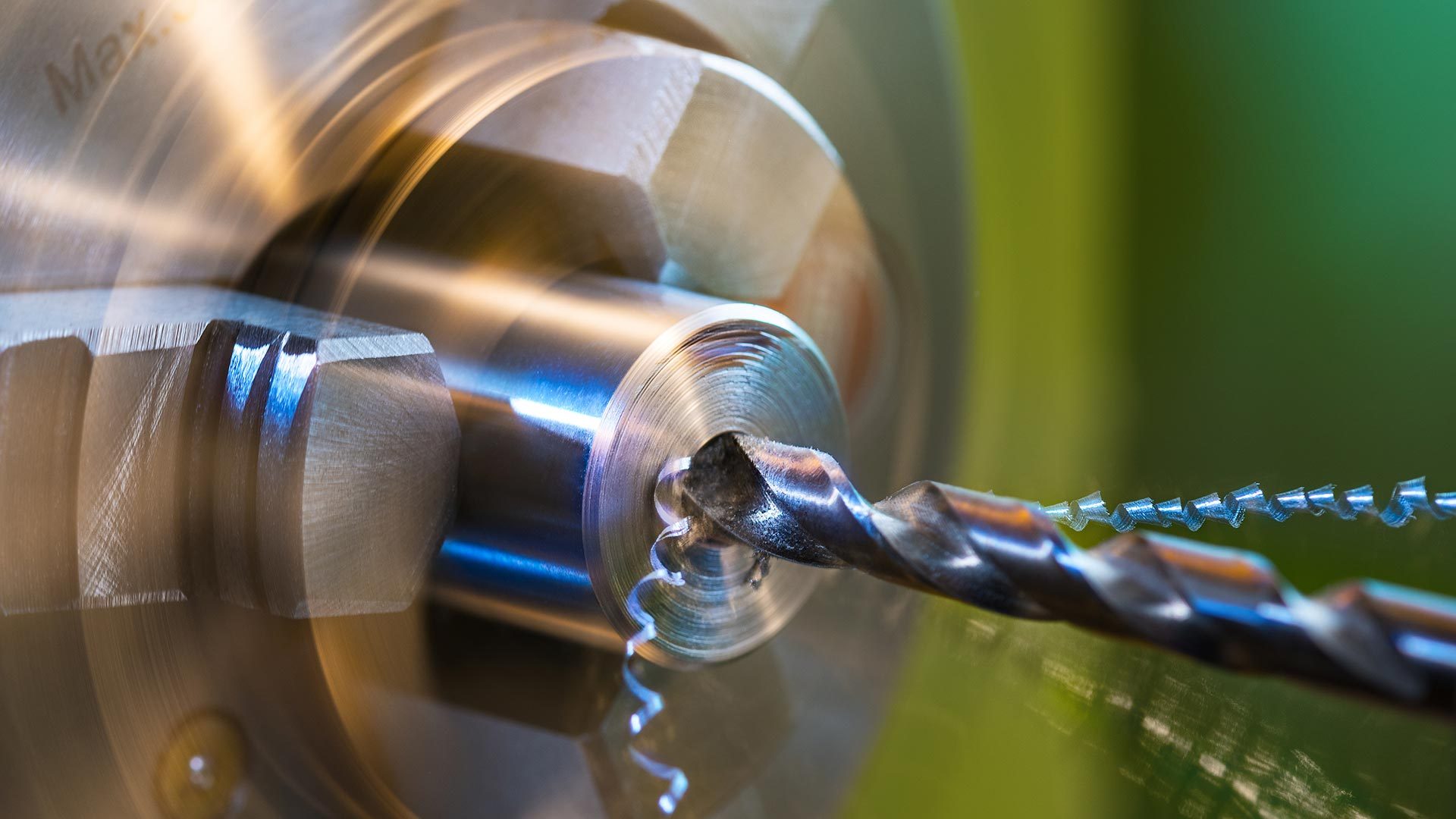

It’s crucial for the safety of your tools and yourself that you use the right bit for the job. You will find cobalt drill bits stocked alongside other popular choices, including titanium coated, titanium nitride and tungsten carbide bits. Each of these has its strengths and weaknesses which you should be aware of before buying.

Cobalt vs carbide drill bits vstungstencarbide

The tools and blades are sold separately and they each have an OFFSET dimension. When combined they equal the effective counterbore diameter. For assistance, use our online Tool Selector.

Carbide DrillSet

Cobalt drill bits are incredibly strong. They can be operated at much higher speeds than a standard HSS drill bit. The ability to withstand heat means that cobalt bits perform for long periods without cooling or the need for cutting fluid.

"By using the BSF tool we've gone from using 5 blades per part to only 1 blade. Our cycle time went from 62 minutes to 7 minutes and 45 seconds. And we're also estimating over $130,000 in savings."

Cobalt Drill bits

They are most often used to cut through hardened and abrasive materials. Cobalt bits are able to cut through the most hardened metals, including bronze, cast iron, stainless steel and titanium. They are also able to cut through weld seams.

HSS bits are hardwearing and heat resistant. The large concentrations of chrome and nickel in stainless steel ensure that HSS bits are super strong and durable. HSS drill bits are capable of safely drilling through hardwood, some metals and plastic. They’re safe to operate at high speeds (RPM) and provide long-lasting performance – as long as they are maintained.

Cobalt vs carbide drill bitsreddit

HSS and cobalt drills need to be cared for and maintained to ensure they deliver consistent performance. Even the hardest wearing materials can become blunted or dulled after a period of hard work. Using the correct drilling technique improves the lifespan of any drill bit.

Carbide drill bitsfor hardened steel

If you’re unsure of the equipment you need, then speak to us. At R.D. Barrett we’ve been supplying the public and the trade with high-quality tools since 1975. We’re always happy to answer any questions you might have, and give you the benefit of our experience to ensure you have the right tools to do the best job.

Need help selecting a tool? Visit our online Tool Selector and go to the Locate Agent page on our website to find your local technical sales representative. For more assistance, contact us at info@heuletool.com or 513-860-9900 and we'll be happy to point you in the right direction.

Sturdy, hardwearing and robust, modern metal drill bits can cut through the toughest materials with no trouble. When it comes to drilling, selecting the right tool for the job is crucial. In this article we describe the difference between High-Speed Steel (HSS) and cobalt drill bits, their strengths and weaknesses, and when you should use them.

Efficient Operation: Operates without the need to rotate the workpiece, utilizing a smoothly swinging blade that activates by spindle rotation and retracts through internal coolant or air pressure.

Over time, HSS drill bits can become blunt and need to be sharpened, which demands specialist tools that aren’t always available. If you’re using HSS drill bits for long periods or at high RPMs, you may need to use cutting fluid to keep the bit cool.

The strength of cobalt means that drill bits are better suited to the tough challenge of cutting through steel. Cobalt bits aren’t suitable for general applications. For less intensive operations, like drilling through wood, plastic or light metals, an HSS drill bit is perfect.

Titaniumvs carbide drill bits

Designed for CNC Machines: Compatible with CNC machines that support through-spindle coolant, requiring a minimum of 300 psi for optimal performance.

The BSF tool is a standout in precision engineering, particularly revered in the aerospace and automotive sectors for its single-operation back spotfacing and counterboring capabilities. This tool is engineered to eliminate the need to rotate the workpiece, streamlining production and enhancing efficiency.

Optimal Cutting and Chip Removal: Special coolant pipes and chip-guiding geometries ensure continuous flushing of the blade window and the blade, promoting superior chip removal and consistent cutting performance.

TungstenCarbide Drill Bits

Cobalt vs carbide drill bitsfor steel

R.D. Barrett was established in 1975 by Ron Derek Barrett, an ex employee of both DS & G Lathes and Ford Motor Company. We hold one of the UK largest stock of engineering tooling.

Cobalt bits are a combination of steel (or another alloy) mixed with a small percentage of cobalt, typically between 5 – 7%. Cobalt has a melting point of 1495°C and a boiling point of 2927°C, which makes it perfect for use at high temperatures. By combining a small amount of cobalt with another alloy, the results are incredible.

High Performance: Counterbores up to 2.3 times the diameter of the drill bit, featuring replaceable carbide-coated blades that extend tool life.

Advanced Mechanics: Functions without an anti-rotation device, spindle direction change, or machine modifications, thanks to a simple swing mechanism enhanced by internal coolant pressure.

The cutting edge on a good quality cobalt bit should last for longer than a standard HSS bit. Like other HSS bits, they are corrosion-resistant, which means they should retain their condition in all storage and usage conditions they’re likely to experience. However, cobalt can be brittle. If your cobalt drill bits aren’t cared for properly or are dropped, they can break – which can prove costly.

0086-813-8127573

0086-813-8127573