C40 BLADE DEBURRING TOOL ID: FN50C40 - deburring blade

After selecting a tool that does not interfere with the part during the initial plunge, you may then widen the groove inward towards the center or outward from the initial groove. It is normally recommended to start at your outside targeted groove diameter and make your way inward for better chip control.

Hardness is the measure of the resistance of the material to deformation or indentation. The testing falls under non-destructive testing method. It is usually determined by the brinell and rockwell testing methods. It is measured in BHN, HRB and HRC.

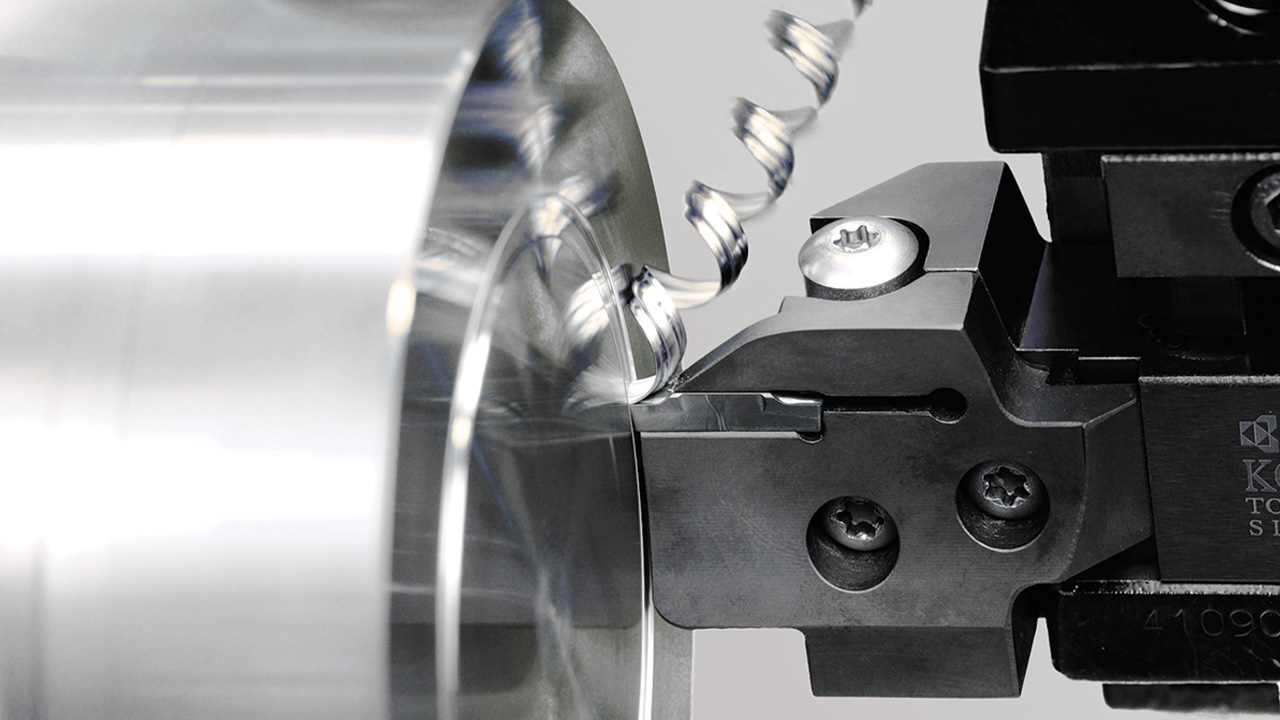

Face groovingtool holder

Explore our SGS branded high-performance and versatile solid round tooling options. Our quality tooling not only ensures precision but also minimizes downtime, allowing for increased material removal per hour. Explore a range of options including end mills, drills, routers, countersinks, and more to find the perfect tools for your specific needs.

Precipitation Stainless steel has 15-17% Cr content and 3-5% Ni content. They have offered the combination of properties like excellent corrosion resistance, strength and hardness. Various heat treatment processes are used to optimize the mechanical properties of the material. They have great oxidation resistance and good machinability. They have high tensile strength, toughness and hardness up to 41HRC.

Yield Strength is the maximum value of stress that can be applied on the specimen before it begins to start plastic deformation. In engineering terms, it is usually the value of stress at 0.2% permanent strain. The ultimate tensile testing machine is used for determining the yield strength. It is usually measured in N/mm^2. This testing falls under the destructive testing method.

Face groovingtool range

Martensitic stainless steels have almost same level of chromium content like ferritic. However, they have relatively high carbon content i.e. 0.1-1%. They are also magnetic and heat treatable. In the annealing condition, they have almost same mechanical properties as the ferritic stainless steel. For enhancing the properties, they have to go through the QT process (quenching and tempering). With QT process, properties like toughness and elongation of the material improves along with almost same level of strength and hardness.

Tungaloyface groovingtools

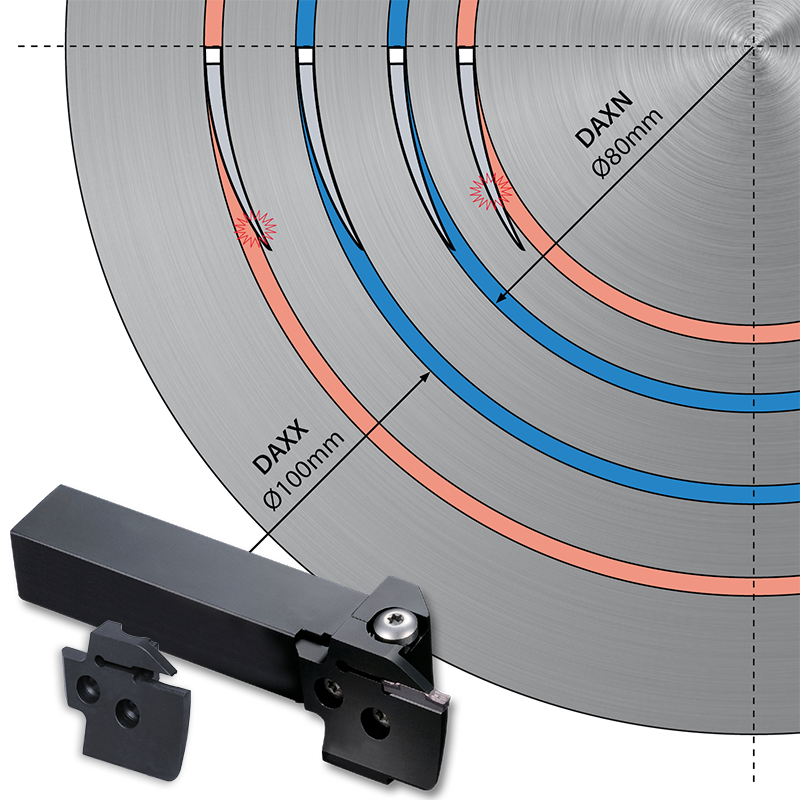

Indexable face groove holders are listed with a minimum face groove diameter (DAXN) and a maximum face groove diameter (DAXX). These two measurements indicate the diameter range for the initial plunge to keep the curved blade of the cutter from interfering with the edges of the groove when entering the workpiece. The blades of these face groove tools provide added support under the insert to give the holder the rigidity needed to eliminate chattering and vibrations from occurring. These blades are designed with a curved side to follow the initial groove into the workpiece without contacting the edges of the groove.

With replaceable head face grooving systems, the blades are interchangeable with the holder allowing the operator to easily replace a damaged blade or switch out sizes without removing the holder from the machine. With these systems, the blade is what will determine the groove width, maximum depth, and diameter ranges that can be achieved.

DovetailFace Groovinginserts

The author is a Sales Engineer with Ambica Steels Limited. He is also fond of writing on Technology and Steel Industries.

Machinists require reliable solutions to tackle intricate tasks efficiently. Indexable tooling provides exceptional flexibility, quality, durability, and delivers high-performance results. Customize your tooling for specific tasks by choosing the ideal combination of inserts and holders to optimize performance.

Face grooving is not always a straightforward process. Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. However, you also need to account for the tool and workpiece clearances on the initial plunge to avoid costly damage to the workpiece and toolholder.

Duplex Stainless Steels are the only family of steel that contain both austenitic and ferritic microstructure. They contain 18-28% chromium content, 4.5-8% nickel content and 2.5-4% molybdenum contents. They have high resistance to corrosion and halide attack. That’s why they have used in the heat exchangers, chemical tanks and refineries. They have higher values of yield and tensile strength than austenitic and ferritic grades. It is very difficult to perform cold working on the duplex steels.

All in all, mechanical properties play a crucial role in the selection of material. They will give a great choice to the manufacturers to select the best material as per their application.

ISCARface grooving

Deepface groovingtools

Toughness is the capacity of the specimen to absorb energy before failure. It is determined by two methods i.e. Charpy and Izod. The most common method used in the industry is Charpy V notch test. It is measured in terms of joules. The absorption rate of energy is high for tough material and very less for brittle materials.

Elongation and reduction of area are the properties which also plays a major role in the selection of material. They are also evaluated with the tensile and yield strength testing. Both factors are defined in percentage forms. Elongation is the ratio of the final length by the original length of the specimen. Final length is the difference between the length obtained after fracture and original length of the specimen. Reduction of area is the ratio of the final cross sectional area and the original cross sectional area of the specimen. Final cross-sectional area is the difference between the original cross sectional area and the smallest cross sectional area of the specimen after a fracture.

Now a day, steel industry has a major influence on the commercial market. Deviation in the industry has a huge impact on various segments in the market. All categories of steel have distinct characteristics in terms of different chemical and mechanical properties. Out of several categories, stainless steel is one of the premium family which has the fastest-growing rate in the market so far. The major reason behind the increased utilization of stainless steel is their corrosion resistant nature, durability and recyclability. It is extremely versatile in nature because of its exceptional mechanical properties such as high formability, structural strength and impact resistance. It has a minimum 10.5% chromium content. This family has several sub categories i.e. Austenitic, Ferritic, Martensitic, Duplex, and precipitation hardening. These sub-categories have different chemical and mechanical properties that give the best option to the manufacturers for choosing the particular material as per their application requirement. Mechanical properties are a measure of the material’s response to an internal and external applied force and play a huge role in the selection of the material. The important properties that need to be considered while choosing the material are yield strength, tensile strength, elongation, reduction of area, hardness and toughness.

Ferritic stainless steels have commonly 10.5 to 18% chromium content. It has very less carbon contents. These grades are magnetic in nature and have poor weldability. They have moderate corrosion resistance and are not susceptible to stress corrosion. As compared to austenitic family, cold working has very less impact on them. Tensile and yield values increases up to a lesser extent after cold working. The standard ferritic grades are tough at room temperature however the toughness reduces with decrease in temperature.

When performing face grooves around a boss on the workpiece, you need to choose a toolholder that will give you the needed reach, groove depth, and face groove range to clear any protrusions.

Tensile Strength is the resistance of steel to failure under external tensile forces. It is measured by the maximum stress that the specimen can withstand while being pulled out by tensile forces before failure. It is determined by the ultimate tensile testing machine. It is usually measured in N/mm^2.

Austenitic stainless steel family has the highest application in the commercial market. In general, at least 16% chromium contents are present in it. It also contains high nickel content which enhances various properties such as fabrication & corrosion resistance. They are non-magnetic in nature. They have far superior properties like yield strength and tensile strength than carbon steel. The yield strength of austenitic stainless steel is 35-50% of the tensile strength but in mild steel, yield strength has higher proportion of the tensile strength i.e. 65-70%. Tensile and yield strength can also increase up to a greater extent by performing cold working operations. These materials have the ability to be work hardened to very high strength levels as compared with conventional materials. They have elongation values on the higher side so it signifies that they have excellent formability. They have extremely good toughness and impact strength at room temperatures but decreases at sub-zero temperatures. Also, the impact strength value of the material will decrease by performing cold working.

To view an example of this, the diagram on the right features a KGDFR-80-2A-C blade with a 2mm groove width (CW). This holder has a minimum listed face groove diameter (DAXN) of 80mm and a maximum face groove diameter (DAXX) of 100mm. A starting groove diameter larger than 100mm or smaller than 80mm will cause interference with the curvature of the blade inside the cut during the initial plunge. This interference can be catastrophic to the blade, insert, and workpiece.

0086-813-8127573

0086-813-8127573