California Code, BPC 22450. - 22450

Millingspeed andfeedCalculatorfree download

Speed andfeed formula

Firearms manufacturers turn to RobbJack’s proven solutions for high-performance machining in everything from aluminum to hardened steel to increase output by up to 500% on your current equipment.

Choose the correct tap or die size and type. This will depend on the material you are working with and the size and type of thread you need to create.

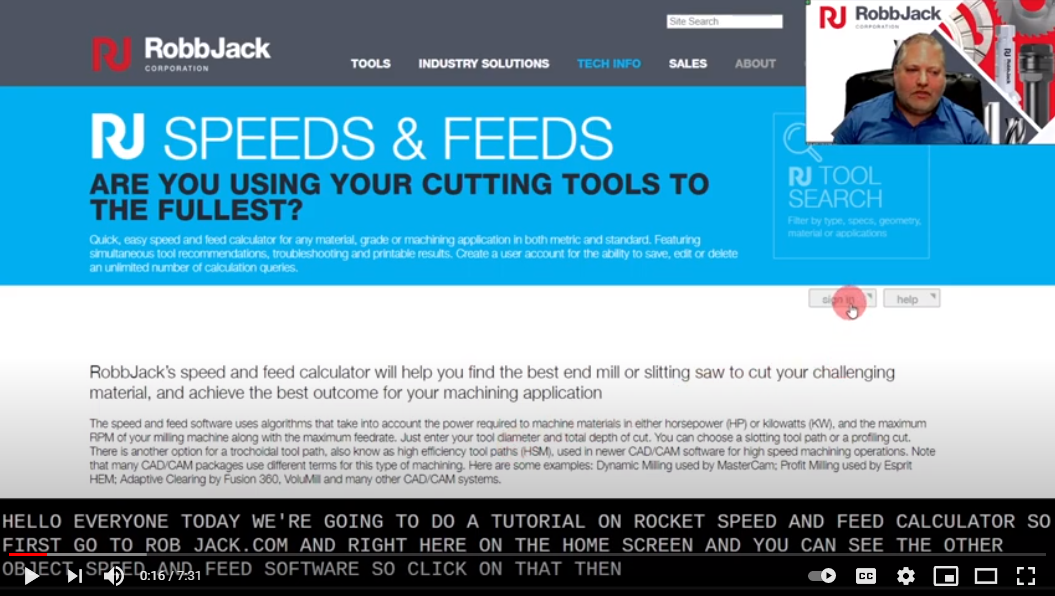

Quick, easy speed and feed calculator for any material, grade or machining application in both metric and standard. Featuring simultaneous tool recommendations, troubleshooting and printable results. Create a user account for the ability to save, edit or delete an unlimited number of calculation queries.

If using a tap, secure the material in a vise or clamp. If using a die, insert the rod or bolt into the die and secure the die in a vise or clamp.

Speed and feeds calculatorfor milling

Just click the “Sign In” button at the upper right of this page to create an account, and get started now! Have questions about how to make the most of Speeds & Feeds? Click HERE or on the image below for a quick video tutorial:

Speed andfeedcalculatordrilling

If using a tap, apply cutting oil to the tap and start the thread by turning the tap clockwise. If using a die, apply cutting oil to the rod or bolt and start the thread by turning the die clockwise.

End Mill speedsand feeds calculator

The RobbJack DM/MDM Die/Mold Carbide end mill offers tighter tolerances, lasts longer in difficult areas like parting lines, and produces better finishes that reduce or eliminate the need for polishing.

Making the switch to aluminum for lightweight, high-performing automotive applications? Only RobbJack's A1-303 met this machining requirement where over 20 other toolmakers failed. See the case study that proves it.

Making the switch to aluminum for lightweight, high-performing automotive applications? Only RobbJack's A1-303 met this machining requirement where over 20 other toolmakers failed. See the case study that proves it.

The speed and feed software uses algorithms that take into account the power required to machine materials in either horsepower (HP) or kilowatts (KW), and the maximum RPM of your milling machine along with the maximum feedrate. Just enter your tool diameter and total depth of cut. You can choose a slotting tool path or a profiling cut. There is another option for a trochoidal tool path, also know as high efficiency tool paths (HSM), used in newer CAD/CAM software for high speed machining operations. Note that many CAD/CAM packages use different terms for this type of machining. Here are some examples: Dynamic Milling used by MasterCam; Profit Milling used by Esprit HEM; Adaptive Clearing by Fusion 360, VoluMill and many other CAD/CAM systems.

Taps and dies come in a variety of sizes and types, depending on the size and type of thread you need to create. It is important to choose the correct size and type of tap or die for your specific application.

Speed and feeds calculatorapp

If using a tap, reverse the tap and turn it counterclockwise to remove it from the material. If using a die, reverse the die and turn it counterclockwise to remove it from the rod or bolt.

Feeds andspeedscalculatormetric

Start a search by selecting the type of tool you're looking for. Then pick the material you will be cutting to limit the list to tool series with the correct geometry. Further limit the list by adding dimensions, characteristics, applications!

Round die: This die is used for creating external threads on rods and bolts. It is often used in combination with a die handle or holder.

Bottoming tap: This tap has a much shorter taper than the other two types and is ideal for use in blind holes, where it is important to ensure the full depth of the hole is threaded.

Taps and dies are tools used to cut threads into metal and plastic surfaces. Taps are used to create internal threads (such as those found on nuts and bolts), while dies are used to create external threads (such as those found on screws and bolts).

Spindlespeed and feeds calculator

The speed and feed calculator provides over 50 years of machining experience to give the best speeds and feeds possible. The program will recommend the ideal solid carbide end mill, slitting saw or PCD and diamond coated tool for your application. The software will also pick the best PVD coating for the job including AlTiN, TiCN, TiN, DLC, and diamond coatings. It will give you the recommended chip load per tooth (CLPT), feed rate, horsepower needed, axial depth of cut, and radial width of cut for both roughing and finishing. The results or inputs can be entered in Metric (mm, KW, mm/min.) or in inch mode.

Complex machining problems often require creative, custom solutions. RobbJack has been the “go to” supplier of solid carbide tools for over 50 years, with a proven history providing incredibly effective solutions.

Taper tap: This tap has a more gradual thread starting point and is ideal for starting threads or for use in softer materials. The taper tap can also be used for through holes, as it helps guide the tap through the material.

Creating threads on a metal or plastic surface is a common need in many mechanical applications. One of the most popular methods of creating threads is by using taps and dies. In this guide, we will explore how to use taps and dies to create threads.

Hex dies: This die is used for creating external threads on hexagonal bolts and is often used in combination with a die handle or holder.

0086-813-8127573

0086-813-8127573