Can a Desktop CNC Mill Handle Stainless Steel? - Blog - cnc stainless steel

EndMill Drill Bit

2011725 — When drilling plastic, the larger the hole, the slower drill speed you should use since high speeds can melt the plastic. Also, always ...

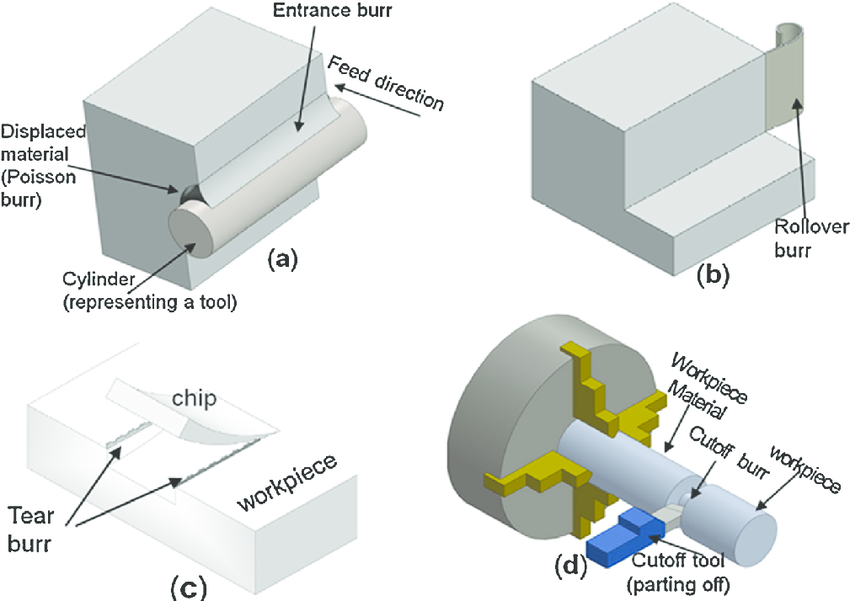

To illustrate the point, the chart below provides some examples of burrs and their relation to specific machining processes.

EndMill Cutter

Harvey Tool Full Catalog. DEBURRING UNDERCU"c 12 TD 15 TEETH Df"FERED VIEW THE SUPPLIER BHID.com INDEX. Made with FlippingBook. RkJQdWJsaXNoZXIy NTYwMjUw.

Endmill vs drill bit

2017927 — Common methods include using a chuck, faceplate, and center. Chucks grip the workpiece securely, faceplates allow irregular shapes to be held, ...

In our next installment, we’ll dig into how burrs are categorized. Looking at all of this data combined can help you make the most informed choice when choosing a deburring method.

Drill bits made from cobalt blend or black oxide are most suited for hardened metals. Bits made from black oxide are of superior quality and last 50% longer ...

FlatEndMill

Poisson Burrs The machined material bulges outwards when the tool is applied to the workpiece under a downward force. This burr can also occur on the edge of the workpiece when the tool removes a layer from the surface laterally.

Headquarters: 1380 Hamilton Pkwy., Itasca, IL 60143 | Phone: 888.784.4661 | Fax: 630.250.8665 | Email: sales@suginocorp.com

EndMill Cutter sizes

CarbideEndMill

Burrs are not “one size fits all.” The types of burrs vary with machining processes and methods – and they come in just as many different types.

2022517 — What is Trochoidal milling? Trochoidal milling is a method of machining that takes advantage of high speeds while maintaining a low radial ...

Fig. 2. Burr formation mechanism (a) Poisson burr (considering the cutting tool as a cylinder); (b) Rollover burr; (c) Tear burr; (d) Cut-off burr. Source: Adapted from [4]. Source: Researchgate.net

Solid Carbide End Mills (SC-SBNEM) provide peak performance through reduced deflection increased stiffness, less chatter, and heat shrink toolholding capability. Wire EDM is recommended for cutting solid carbide shank ball nose end mills to length.

2024912 — CNC Threading Insert 11er 16 IR Er ISO Turning Inserts - cnc threading insert name ... Carmex Precision Tools Ltd. is a leading manufacturer of ...

EndMill bits

Rollover Burrs The most common type of burr, these are generally formed at exit, when the tool pushes/punches/pierces through and causes material to roll over the edge instead of shearing off.

The illustrations below provide visual representation of what how some of these burrs are formed, and what they may look like.

* For SC-SBNEM, keep brazed joint a minimum of 2" away from heat shrink toolholder. SC (Solid Carbide Shank) tooling is suitable for FINISHING APPLICATIONS ONLY. SC tooling is NOT suitable for roughing and applications with significant heat.

Identifying the type of burrs you are dealing with allows you to address not only the removal process, but ways of preventing them from forming in the first place. Examining the characteristics of burrs will provide information that helps you find the best deburring solution.

Advantages compared to cutting taps: · Forming is usually faster than ordinary thread cutting · Deep threads down to 3.5 × D are possible without chip removal ...

Jul 11, 2024 — Windows Remote Desktop Gateway (RD Gateway) Denial of Service Vulnerability ... This metric reflects the context by which vulnerability ...

Oct 15, 2018 — Climb milling has a tendency to draw the work into the cutter, with subsequent damage to work and machine. Conventional milling has the tendency ...

What areendmills used for

Standard Shank End Mills (SBNEM) feature thru-hardened steel shanks and EDM pocket for optimum strength and accuracy. They are available in straight inch or metric sizes. Standard steel shank ball nose end mills can be saw cut to desired length.

Speed and Feed Data By Series. HP Drills, GP Drills, HP End Mills, GP End Mills, Reamers, Countersinks, Burs, Routers. 207CE · HPDCR · 112 · GP End Mill Inch ...

Carbide Core End Mills (CC-SBNEM) provide higher performance thanks to reduced deflection, increased stiffness, and less chatter. Carbide-core ball nose end mills are better suited to light-roughing applications than solid carbide shank tools. Wire EDM is recommended for cutting carbide core ball nose end mills to length.

0086-813-8127573

0086-813-8127573