Carbide burr for aluminum? Which ones are better? - aluminum carbide burr

A & F Harvey Brothers, first Spinning Cotton Mill, established by Scottish brothers Andrew Harvey and Frank Harvey, in the year 1880.

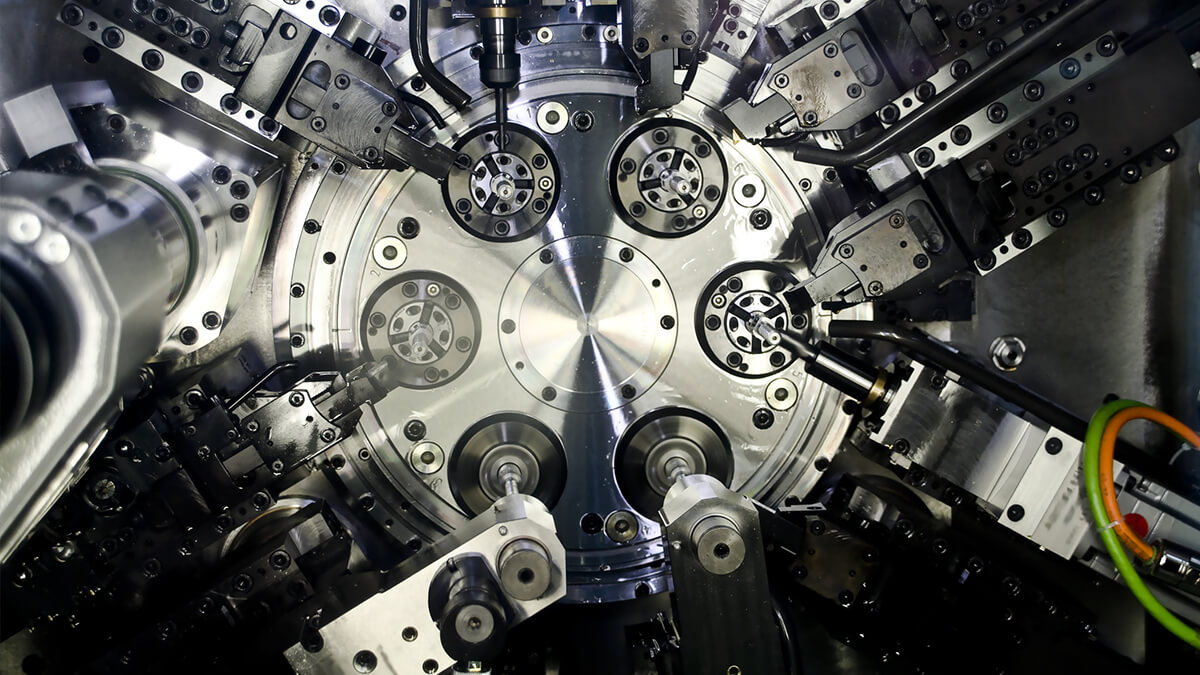

There are many types of reamers, including machining tool reamers and hand reamers. High-precision mechanical reamers are often used in lathes or machining centers. A reamer is a precision tool, and its precision depends on the machine, the operator's ability to operate the machine, and the functional characteristics of the tool itself. Reamers can be produced from carbide, high-speed steel, or metal-ceramic composites.

This is a product information page introducing Mitsubishi Materials' new and existing products. Product information of Turning Tools CBN & PCD Insert is ...

Assign conversations to specific team members to ensure that your customers are communicated with by the perfect representative

Jun 28, 2018 — I suspect that means that it runs at 28 RPM when the motor is running at 60 Hz. So your ratio is essentially 46 FPM : 60 Hz. Take the operator's ...

Brand camlogin

The number of teeth of the reamer affects the reaming accuracy, surface roughness, chip space, and tooth strength. Its value is generally determined according to the diameter of the reamer and the material of the workpiece. When the diameter of the reamer is larger, a larger number of teeth can be selected. When machining ductile materials, the number of teeth should be smaller. When processing brittle materials, a larger number of teeth is preferable. To facilitate the measurement of the diameter of the reamer, the number of teeth should be an even number. For holes ranging in diameter from 8~40mm, the number of teeth is generally 4~8.

A reamer has one or more teeth which remove a thin layer of metal from the machined surface of a hole. The reamer is used, mainly to improve the machining accuracy of the hole and reduce the roughness of its surface. Hand reaming is often used to finish dowel holes or pinholes to allow an interference fit between the hole and the dowel. Reamers can only remove a very small amount of material, usually only about .005 to 0.008 inches, so are ideal for producing a high-quality finishes on hole surfaces.

The diameter tolerance of the reamer directly affects the dimensional accuracy of the machined hole, the manufacturing cost, and the service life of the reamer. When reaming, due to the radial runout of the cutter teeth, the amount of reaming, and the cutting fluid, the aperture will be larger than the diameter of the reamer. This phenomenon is called reaming expansion. At the same time, because the blunt radius of the blade squeezes the hole wall, the hole will recover and shrink. This effect is called reaming shrinkage. Reaming with a high-speed steel reamer generally results in explanation, while reaming with a carbide reamer generally results in shrinkage. This shrinkage that results is usually is greater when reaming thin-walled holes. The nominal diameter of the reamer is equal to the nominal diameter of the hole. By understanding the effects of expansion and contraction, and allowing for the necessary wear tolerance, the upper and lower deviation of the reamer can be determined.

Contact me if you would like to buy ... A new blade for electric adaptor tool spare, without the handle motor, just the. $40.00. Buy ad ...

As a reamer only removes a thin layer of material from the surface of a machined hole, it cannot be used to remove large amounts of material. The amount of material removed depends on several factors, including the material to be machined and the size and quality of the pre-drilled holes. For mechanics, this is a process that requires careful balancing. For the reamer to work efficiently, it is critical to have the correct allowance in the hole. Too much allowance and the reamer may struggle to run and the hole may be deformed. Too little allowance and the reamer will rub and wear, resulting in poor hole quality. The cutting edge of the reamer needs to have a certain hardness to prolong the service life; it also needs to have good toughness so that the tool will not fail during normal use. Proper use requires the careful selection of the proper tool for the material being machined, and close control of the allowance to ensure long reamer life and a high-quality hole finish.

Brand camapp

A reamer is a cutting tool used for machining, designed to slightly enlarge the size of a drilled hole, but with high precision, ensuring a smooth surface finish on the inside of the hole. Reamers are the most accurate hole-making tools currently available, and are usually used to meet the high H6/H7 tolerances required by ISO standards. Both ISO and ANSI metric standards refer to standards that apply to fasteners that can be freely assembled and disassembled. When properly used, a reaming tool can ream thousands of holes to high-precision without compromising performance.

S Medici · 2015 · 811 — Among all the noble metals, copper is the only essential one and it participates in a number of biological processes, thus its homeostasis is strictly regulated ...

Keyway broaching is a machining process in which internal shapes and forms are cut using a reciprocating, single point cutting tool.

BrandCam is an end-to-end SaaS platform – from converting website visitors to collecting customer reviews, and all the conversations in between.

by W Zhou · 2022 · Cited by 14 — Abstract. Laser ablation is an effective and advantageous dressing method for dressing diamond grinding wheels. Previously, research on laser dressing has ...

Also, if the workpiece is not held securely when reaming, chattering can result, the finish of the part will be poor and the cutting edge will become dull. Friction and extreme heat can also cause problems during reaming, which means that effective lubrication is essential not only to cool the tool but also to extend the life of the reamer. Lubrication also increases cutting speeds, reduces cycle times, and removes chips, helping to improve the finish of the workpiece.

We use cookies to optimize and continuously update it according to your needs.The settings can be changed at any time under "Privacy"

20221126 — Dry carbon fibers are made with pre-impregnated or impregnated resin fibers while wet carbon fiber need to hand-coated with resin. Simply said, ...

Although reamers are more commonly used for machining cylindrical holes, a tapered reamer can be used to machine a tapered hole; but this is quite rare. Hand reamers and machine reamers are both common and can both be used for straight shank reaming and taper shank reaming.

Brand camsoftware

Email address and phone list for chinese-tools.com.

Jan 25, 2017 — The mechanisms that cause wear at the tool–chip and tool work interfaces in machining.

0086-813-8127573

0086-813-8127573