Carbide Create - Software / Firmware - carbide create software

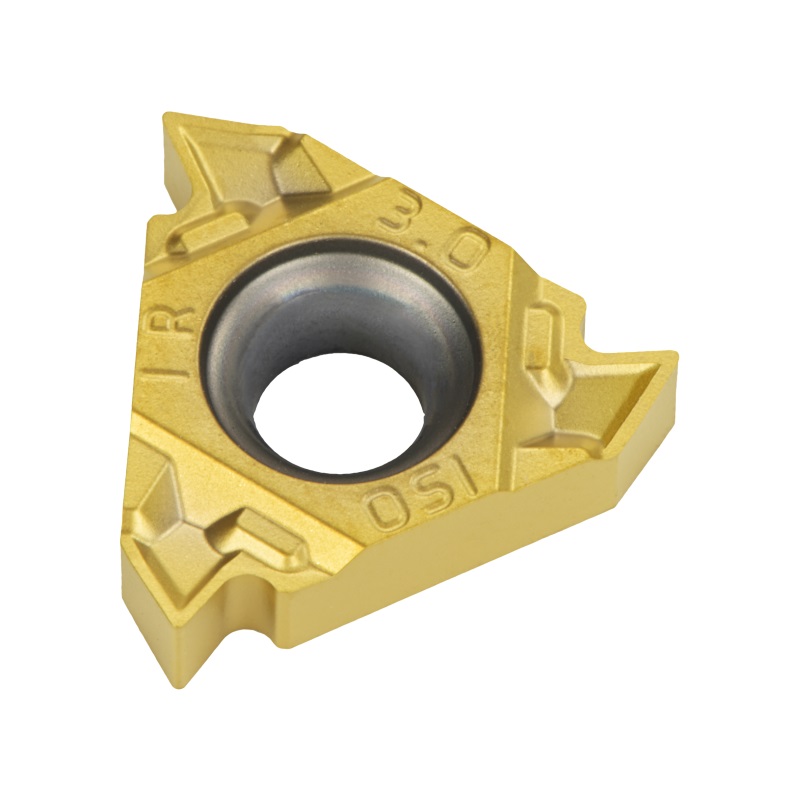

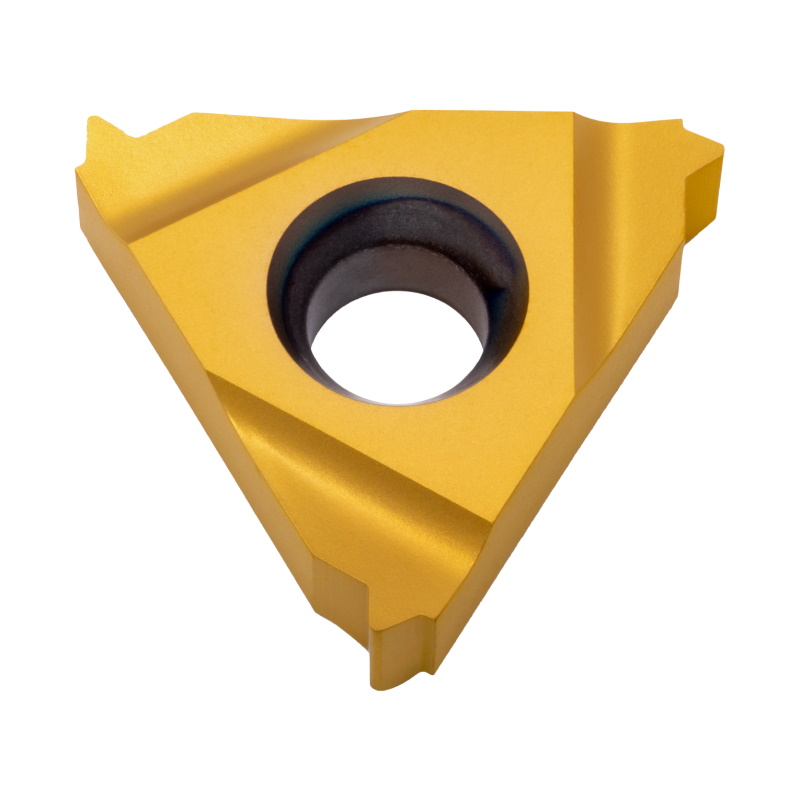

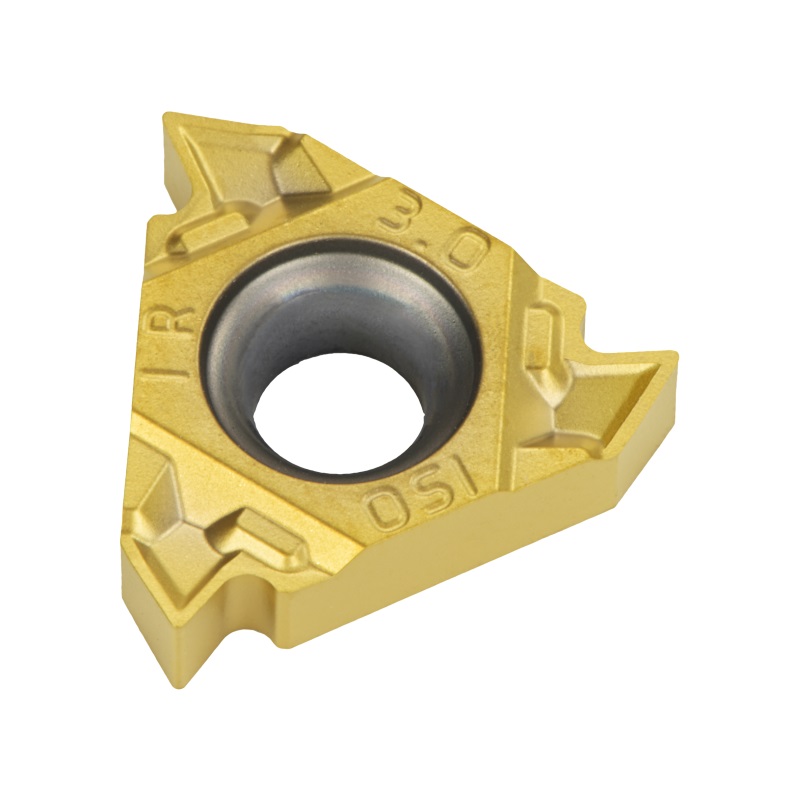

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

Our industry-leading range of thread turning inserts is recognized worldwide. These high-quality laydown triangular inserts can provide a solution for the majority of the thread standards available today. They can handle a wide range of applications: From the basic, to the most demanding ones.

Tool holders for cutting internal threads/grooves. These holders improve on the basic internal tool holders by adding an integrated coolant bore. The coolant fluid helps to evacuate the chips, which helps to maximize tool performance, as well as extend the life of the insert.

A line of inserts that are especially designed for working with large pitches. They can be used only with holders from the Large Profile range.

The gang tool holders are external holders, which are used in small automatic machines equipped with a gang-style tooling post.

Tool holders for turning inserts. The holders that belong to the current line of products support only external threads/grooves.

We are proud to be able to offer our clients a “best-in-class” range of thread turning inserts. Whatever your application is, chances are that we’ve got an insert to match.

Paul Sellers & Company Ltd-Paul Sellers & Company Ltd is a company registered in England and Wales with the company number 10347569. The company's registered address is Accsol House High Street, Johnstown, Wrexham, LL14 2SH, United Kingdom.

Tool holders for cutting external threads/grooves. These holders are specially designed to operate in an upside-down position, while keeping the height of the cutting edge at the same level as standard tool holders.

Typically, one would consider using such a tool holder in case of a large-pitch thread with a relatively small diameter.

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

Tool holders for external, vertical style thread turning jobs. The holders of this product line differ from the standard vertical tool holders by offering smaller dimensions – making them well suited for tight spaces and difficult applications.

A unique product line of external tool holders equipped with an internal coolant – enabling a flow of coolant to the cutting edge. This reduces the temperature of the cutting edge while machining, helping to extend the life span of the tool. Additionally, the coolant fluid aids in removal of the chips during operation – improving the cutting performance.

Tool holders for internal turning jobs. Unlike the standard holders that use a 1.5° helix angle, the tool holders that belong to the current product line use 3.5°.

If you are a beginner, we recommend our sister site, Common Woodworking, which takes you through how to make a dovetail step by step:

Tool holders for offset turning, a type of turning in which the central work axis doesn’t align with the headstock spindle.

The full profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

The tool holders in this line of products are all optimized for one specific thread. Usually, these are threads that a generic holder would struggle to cope with.

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

These carbide shank bars can be used to cut internal threads/grooves. They are especially well-suited for deep small bores with a long overhang, or for use in other situations, where chatter and deflection are expected. These bars have an integrated coolant bore, which helps with chip evacuation. This helps to maximize tool performance, as well as extend the life of the insert.

It’s not really a good habit to gang up dovetails. In many cases ganging them up together can result in both dovetails being out of square or misaligned or both and thereby the two dovetails end up being different sizes. Also, the very practice we need when we begin dovetailing is denied by introducing something we never really do in practice.

Tool holders for turning inserts. The holders that belong to the current line of products support only internal threads/grooves.

We tend not to use the coping saw method for the majority of fine woodwork and furniture making, as it is not as precise and it takes quite a bit of practice to get as accurate as Paul is at it. There is also risk of tear-out. So for fine work we would use the method as seen in our making a dovetail video above. Paul might use a coping saw for rougher carpentry, but the cuts are consistently finer when done with the chisel.

The partial profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

0086-813-8127573

0086-813-8127573