Carbide Drill Bits - carbide drill bits for hard steel

Recommendations for the machining of Soft Plastic such as ABS, Polycarbonate, Polyethylene, PVC, Polypropylene, HDPE, Polystyrene, UHMW, Extruded Acrylic

Tapping threadchart

The nominal size is the thread concentration, while the thread form designation identifies the thread family the threads belong to (i.e. ACME, UNC, UNF, UNJ, UNS). The material tap is constructed from is typically a tough material like carbide, and the pitch diameter tolerance gives an alpha-numerical code that designates the tolerance for the thread.

By clicking 'Accept', you agree to the storing of cookies on your device to enhance your browsing experience and for analytical purposes. By clicking ‘Reject’, only essential necessary cookies will be stored on your device.

Tappingscrew threads

Accelerate development with instant quotes, expert DFM, and automated production updates.

Recommendations for the machining of composite materials. Includes detailed cutting data breakdown for 66-500 to 66-800 series for full slotting to finishing.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

How to tap threads in metal

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Create an account and upload your part to see what our instant quote process, design for manufacturability feedback, and intelligent platform can do for you. Our CNC machining service can create your parts in as little as 2 days!

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

We exist to eliminate bottlenecks in new product development by integrating the people, processes, and platform you need to source custom parts.

Tap and Die Set

The next largest drill size beyond the calculated diameter should be chosen to tap the hole. So, if you calculate a drill diameter of 0.720”, you choose the next largest tap diameter of 0.750”.

Tapping is the process of creating threads inside of a hole for the installation of a screw or bolt — so a tapped hole is just a hole that is internally threaded. The tapping process starts with drilling a hole that is typically slightly smaller in diameter than the major diameter of the threaded fastener you will use. Here’s the equation for determining the size of the tap to use for ANSI threads:

Our website uses 7 main cookies. A cookie is a small file of letters and numbers that we put on your computer if you agree. These cookies allow us to distinguish you from other users of our website, which helps us to provide you with a good experience when you browse our website and also allows us to improve our site. The cookies we use are "analytical" cookies. They allow us to recognise and count the number of visitors and to see how visitors move around the site when they are using it. This helps us to improve the way our website works, for example by ensuring that users are finding what they are looking for easily. Read more about the individual cookies we use and how to recognise them by clicking here.

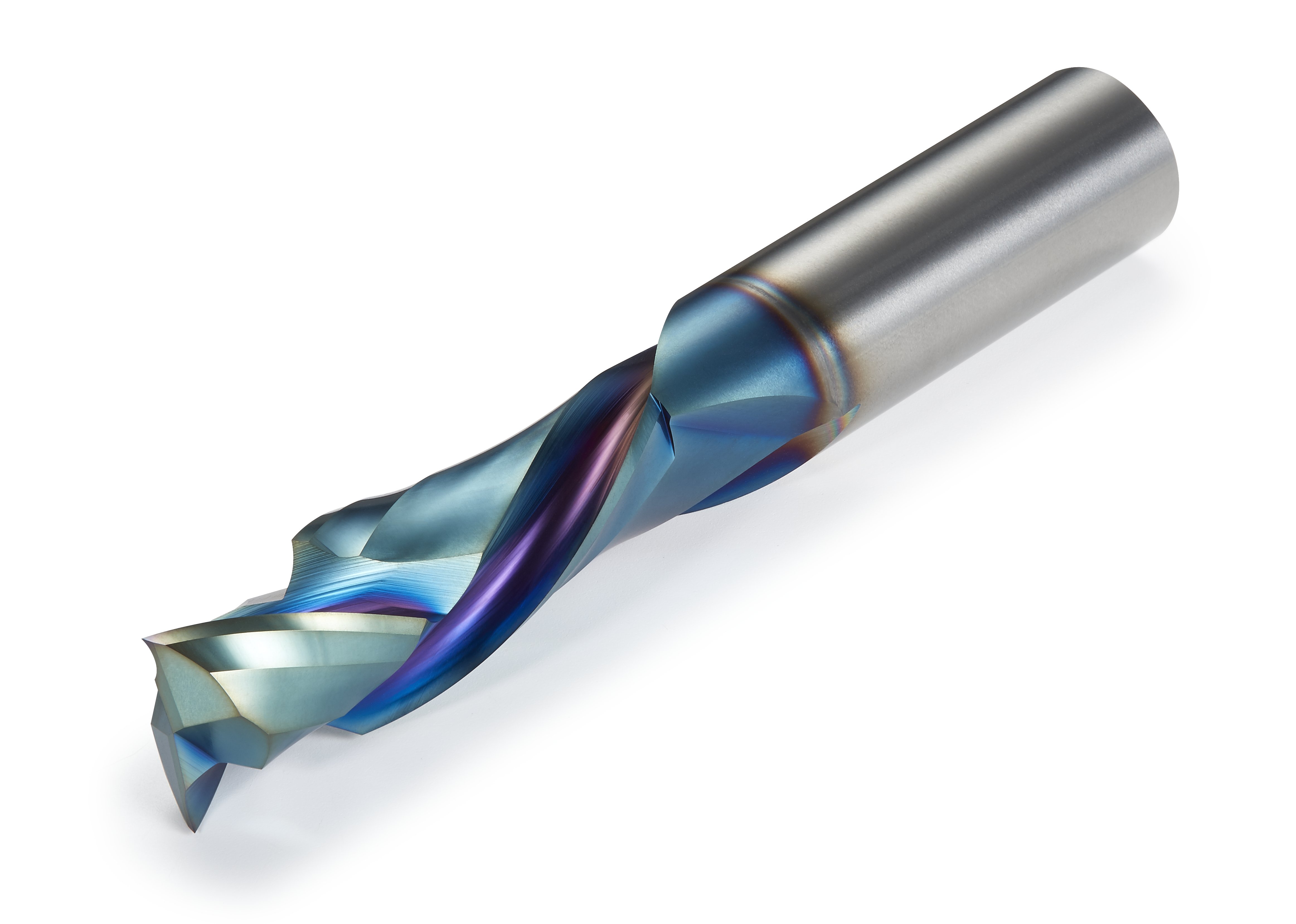

After the hole is drilled, you form the threads on the inside diameter of the hole using a tap. Taps look similar to drill bits, and there are a few different types of taps: hand taps, power taps, tapered taps, extension taps, and exotic taps. All taps are marked with a standard designation that includes the following information:

3 types ofthreadtaps

Our trained employees ensure your parts will be delivered on time and to spec.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Threaded fasteners have been around for decades and provide a novel method of force transformation to secure two or more components together in an assembly. Screws, in particular, have been the subject of many mathematical and geometric studies in the past because they act as simple machines that transfer rotational forces, or torque, into a simple linear force. One way to understand this is using the concept of the Archimedes screw — where a rising level of water turns a turbine connected to an electrical generator to generate power from a water source (the Archimedes screw acts as a power displacement pump). Pro-Tip: If you’re tasked with designing a threaded fastener from scratch, advocate for an off-the-shelf solution instead. Otherwise, use threading calculations and fastener calculations to help with your design.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

re-tapping threads

The Calculation:Spindle Speed x Number of Flutes x Chipload (High/Low) = Feed RateThe Calculations are based on depth of cut being 1xD for a standard length tool. For 2xD reduce the chipload by 25% and for 3xD reduce the chipload by 50%.RPM SelectionThe general operating RPM for tooling contained on this site is between 10000 - 20000 revolutions per minute (RPM). These will differ dependent on tool selection due to us putting in some extensive research to see where the tooling best suits. For most materials a good starting point for RPM is between 16000 - 18000. There are a number of different scenarios where this will change (Composite Materials, Honeycomb, Soft Plastic to name a few). If you have any questions then please give us a call or drop us an email.Frequently Asked Questions:

Access a wide breadth of capabilities through our highly vetted network.

While tapping is the process of creating internal threads within a hole, threading is the process of creating external threads on the cylindrical body of a screw, bolt or other part to be assembled (like pipes). When referring to an installation location for a threaded fastener, you may use the term threaded hole or tapped hole but remember that a fastener is threaded, not tapped.

Thread tappingdrill

How to Calculate CNC Router Feed RatesThe chip load is the measurement of the thickness of material removed by each cutting edge during a cut. This is a valuable piece of information that can then be used to calculate new set ups.Chip loads are based on material thickness of average size for cutting edge length of the tool. The calculation below does not apply to thicker material or tools with a long cutting-edge length. These feed rates are only a recommended starting point and do not accommodate all circumstances. Therefore, tooling damage may still occur and use of the calculator does not provide any warranty for tool breakage.

Threading on a screw or bolt begins at the point of engagement of the fastener and continues through the body to the shank, or unthreaded portion, of the fastener. See the image at the beginning of this article for a more detailed refresher on threaded fastener terminology.

Thread tappingtool

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

When designing mechanical assemblies, it’s likely that they’ll require fasteners for assembly. Fasteners like screws and bolts are commonly used to secure mating components, and they usually require some type of hole for assembly. There are many types of holes to use to install fasteners such as countersunk, counterbore, tapped, tapered, spot faced, and screw clearance.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Create high quality custom mechanicals with precision and accuracy.

Now, let’s look at the definition of tapping vs threading, decode the proper use of the terms, and find out which is the correct terminology: threaded holes vs tapped holes.

We exist to eliminate bottlenecks in new product development by integrating the people, processes, and platform you need to source custom parts.

For all your custom CNC part manufacturing needs, Fictiv has you covered. We’re experts at machining any size of tapped holes in a variety of materials, and we simplify custom part sourcing with intelligent, streamlined, automated workflows. Fictiv is your operating system for custom manufacturing that makes part procurement faster, easier, and more efficient.

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

0086-813-8127573

0086-813-8127573