Carbide Endmills - 1/2 end mill carbide

Solar Miniature Series. Microcomputer Construction; VIEW ALL ... Side Cutters & Modeling Knives. Change order. Start; Product number ...

The Fusion Drill Adaptive Cultivator simply attaches to any cordless drill and creates a powerful and lightweight cultivating tool for your establi.

Dapra uses an easy-to-understand system that separates grades by toughness/hardness. Similar coatings are available for each carbide substrate, so choosing the grade begins with the toughness of the substrate desired and ends with the coating of choice.

This is quite simple. A tool with a large diameter is able to mill the part quicker. Limitations apply based on the geometry of the final part.

For example, if certain inside radii are necessary, the tool cannot deviate from them. At the same time, you can use a large tool for milling away the bulk of it and apply a smaller one to finish the inside corners.

The minimum FPT (feed per tooth) for the APET geometry should be .006". This is to get the chip thickness past the T-land edge preparation, allowing the insert to cut, not rub. The minimum FPT for the XPET insert should be .003". Consequently, lighter cuts (FPT) should not be taken with the APET unless other conditions exist that necessitate the use of the stronger edge.

Cobalt-bearing HSS, for example, are suitable for even quicker milling. This makes them sufficiently adequate for most jobs.

Kyocerainsertgrade chart

Keep in mind that these are typical scenarios and this selection process will in most cases result in the correct choice. However, combinations of the above factors can create unique situations that call for unusual grade/geometry selections. The best course of action is to contact your Dapra Applications Specialist for technical support. We are here to help!

Regular carbon steels are usually out of the option pool because of their limited capabilities. HSS (high-speed steel) is therefore the most inexpensive one to get the job done. At the same time, its rate of wear means that in the long run, there are better options.

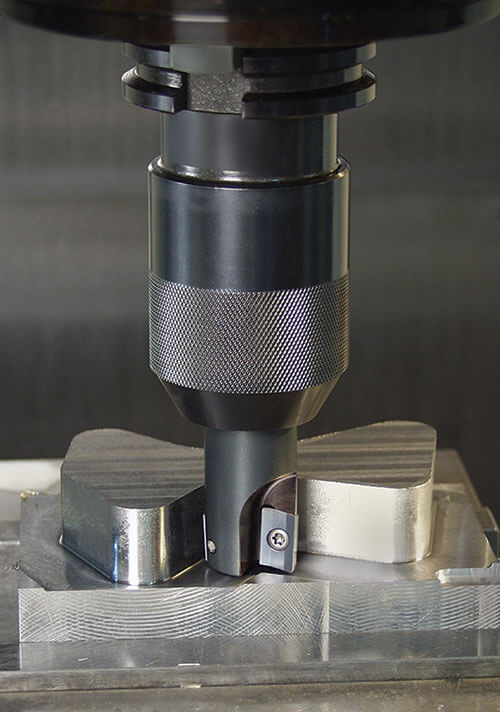

These tools usually have a flat bottom but not always. Round and radiused cutters are also available. End mills are similar to drills in the sense that they can cut axially. But the advantage for milling lies with the possibility of lateral cutting.

The name of this tool says everything you need to know about its purpose. Thread mills are used for producing tapped holes.

The cheapest of the bunch. And this is exactly why it still finds use. As carbon steel is not very durable, it is only suitable for low-speed operations.

XPET-ALU – Sharpest edge. Ideal for aluminums and plastics where high-shear cutting is needed. Creates the lowest spindle load and least noise, but most susceptible to edge chipping.

ISOinsertgrade chart

Woodruff, or keyseat/keyway cutters are used to cut keyslots into parts, for example shafts. The cutting tools have teeth perpendicular to the outside diameter to produce suitable slots for woodruff keys.

For abusive applications, use of the toughest grade is recommended. These would be identified as the following: interrupted cuts; long tool lengths; poor chip evacuation; stainless steels; high-temperature alloys; poor workpiece or machine rigidity; coolant use or very heavy cut depths.

As is the norm in manufacturing, the choice of method or tool comes down to a balance between speed, cost and quality. The cost depends on both the price of the tool, the wear machining results in and the time it takes (speed) to produce the parts.

One of these automated fabrication methods is CNC milling. It is a process where rotary cutters remove material, which makes it the opposite of CNC turning.

Turninginsertgrade chart

As the name says, these are pretty much end mills with a slight difference. The roughing end mill has jagged teeth. These make the cutting process faster than with a regular end mill.

195 Main Street, Lee, MA, 01238 US. Toole Insurance, an ... Employees Size. 10-50 employees. Specialties. Business Insurance, Personal Insurance, Risk ...

Hollow mills are basically the opposite of face mills. Here, the workpiece is fed into the inner part of the mill to produce a cylindrical outcome.

Secoinsertgrade chart

APET – Strong reinforced cutting edge for optimum wear and chip resistance. This geometry will provide the strongest edge, but at increased spindle load and usually higher decibel levels.

High-speed steel, a grade of tool steels, has a few alloying elements added to it to provide better response to heat and wear than regular carbon steel. While the life cycle of such a tool goes up, so does the cost.

The cut bits of metal are smaller than usual and therefore easier to clear. Multiple teeth come into contact with the workpiece at the same time. This reduces chatter and vibration, which could otherwise be larger because of the jagged teeth.

There is a special cutting tool for milling involute gears. There are different cutters available to produce gears within a certain number of teeth.

Indexable Carbide Inserts for threading (metric ISO thread) of steel, stainless steel, and cast iron. Internal threads and external threads. Content: 10 Piece(s) ...

Threading operations are usually carried out on drilling equipment. Using a thread mill, though, is more stable and has fewer limitations regarding the environment.

Dapra's mid grade provides high performance and increased tool life over the toughest grade, due to increased hardness of the carbide substrate. This allows higher speed and improved wear resistance, but at a slightly higher risk of insert chipping.

Insertgrade chart pdf

The helix angle, along with the rotation speed of the spindle, determines the cutting speed or feed rate. A steeper angle is suitable for softer materials and metals.

These are two of the most prevalent milling operations, each using different types of cutters – the and mill and the face mill. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

A predecessor for the end mill. Side-and-face cutters have teeth around the circumference as well as on one side. This makes the functionality very similar to end mills but their popularity has waned over the years with the advancement of other technologies.

Check out our flat wire cutter selection for the very best in unique or custom, handmade pieces from our shops.

Insertmaterial grade chart

Face mills cannot cut axially. Instead, the cutting edges are always located on the sides of the cutting head. The cutting teeth are replaceable carbide inserts.

These abusive applications require a cutting tool with high shock resistance and toughness to reduce the chance of insert chipping. Use of these grades will provide excellent toughness at the cost of some wear resistance properties.

Cemented carbide is another step towards high performance milling because of the aforementioned properties of such milling machine tools. In the long run, they are a more cost-efficient choice while the up-front costs are higher.

Get your groceries delivered today in as little as 60 minutes. · Shoppers carefully pick the freshest items from your list. · Enjoy $0 delivery fees on orders ...

The material of iron nails is generally low carbon steel wire or high strength steel wire. Galvanized Iron Wire Nails. The more commonly used ...

The milling centres do not just perform the cutting automatically, but also the changing of tools. During the average process of creating a finished product from a block of metal, for example, various tools are used.

Dapra's hardest grades provide optimum wear resistance, with the longest tool life possible. However, insert chipping is a more common occurrence when shock is encountered. Dapra's hardest grades are:

201621 — Generally, drills with a high helix angle, polished flutes and 130° to 140° point angle will provide the best chip evacuation and cutting ...

Choosing the right insert geometry and grade for an application can easily make or break a job. Making the right choice requires educating yourself on what types of cutting edge and carbide grades are best suited to the machining conditions present. Typical considerations include:

Face mills are better for high quality cutting. Fly cutters are just cheaper and the cutting bits are often made at the shop by a machinist rather than bought from stores.

Carbideinsertgrade chart

These tools have the same function as face mills. They consist of a central body that holds either one or two tool bits (double-end fly cutters).

This material is harder than high-speed steel but the toughness qualities are not that impressive. The higher hardness provides better protection against wear but lower toughness levels make it a little more susceptible to cracking and chipping.

CNC machining is a highly utilised subtractive manufacturing technology. Computer numerical control systems offer less need for manpower and higher levels of automation.

Specialty Commerce Corp., a multi-channel direct marketing company, engages in selling womens hair fashion products, medical hair loss products.

Cutting ceramics are even harder than cemented carbides but lose in the toughness aspect. Both aluminium oxide and silicon nitride are used to produce these tools with varying properties.

Sandvikinsertgrade Chart pdf

For very stable, high-wear applications in cast iron and nonferrous materials, as well as hard milling of heat-treated materials, Dapra recommends the use of our hardest grades. Application examples include: gray cast irons; aluminum and copper alloys; plastics; light, smooth cuts in any material; and heat-treated steels (typically over 48 Rc).

For stable, steel and ductile iron applications, Dapra recommends our medium toughness/hardness carbide. Examples of some good applications include: uninterrupted steel cuts; good workholding / machine rigidity; short tool / diameter ratios; lighter depths of cut; good chip evacuation; alloys; low and high carbon steels; ductile (long-chipping) irons; and dry machining.

Cutting ceramic tools are prone to cracking when used on hard materials and with high temperatures. Therefore, they are not really suitable for machining steels, for example. Otherwise, a short tool life is to be expected.

With tooling one thousandth of an inch in diameter to six inches, we are your first choice for solid carbide end mills and high performance tooling. Outstanding ...

As you could see, there are a lot of different machine tools available for a wide range of purposes. The same applies to the materials used to make these tools.

Such a coating reduces the stickiness of the cutting material which can be a problem with aluminium. Therefore, less lubricant is necessary during the cutting process.

Choosing the right milling cutters for your job needs an understanding of the materials, parameters and definitely some experience. The final outcome depends on these choices and a machinist must understand what material cutters are suitable for cutting different mediums.

Ball cutters, also known as ball mills, have hemispherical cutting tips. The objective is to maintain a corner radius for perpendicular faces.

Slab mills are not that common with modern CNC machining centres. Rather, they are still used with manual milling machines to quickly machine large surfaces. That is also why slab milling is often called surface milling.

Other factors can come into play, but those listed above are almost always the important issues when determining what geometry and grade to select. Following are some brief suggestions for geometry and grade selection for our Square Shoulder Single-Sided Insert Platform.

There are some different coatings available to protect the tools from wear. For example, a titanium nitride coating increases the tool’s lifespan but also the cost of it.

XPET – Sharper edge for cutting gummier materials such as low carbon steel, stainless steel and high-temperature alloys. Light hone provides some reinforcement and reduces cutting forces and noise. More susceptible to edge chipping.

The selection procedure described here will require your careful consideration of several application conditions and insert characteristics. This may take some time, but the cutting results will be well worth your effort.

0086-813-8127573

0086-813-8127573