Carbide Inserts & Tools - Mumbai - cnc tool insert material

Entry level, manually operated dovetail routing machine to rout a single dovetail keyway with each machining cycle. For Dovetail Key sizes W-0, W-1, ...

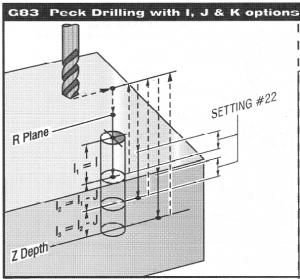

Let’s talk chickens! When chickens eat, they put their head down and raise it up. This movement is called pecking. The chickens’ heads go up and down.

Good Performance and long life. Excellent for making clean and accurate hole on glass and tile. ... Use note: 1. Start your hole diagonally, make a round trace ...

From prototype to production, DATRON Dynamics optimizes your entire machine workflow with touchscreen-enabled DATRON CNC machines. With headquarters located on the East Coast in Milford, New Hampshire, and an office in Livermore, California, we are your one-stop DATRON Partner in North America

Shop Bosch 1/4-in Carbide-tipped Straight Router Bit in the Straight & Mortising Router Bits department at Lowe's.com. Bosch Carbide-Tipped Router Bits ...

Our carbide end mill sets come in a fitted hardwood stand for handy storage on your workbench. Most sets include 6 endmills with sizes 1/8, 3/16, 1/4, 5/16, 3/8 ...

When it comes to finding the best drill bits for metal, cobalt drill bits stand out due to their high heat resistance and ability to maintain their sharpness ...

If you need to make a very deep hole – in excess of 4x your hole diameter, choose the drill. Past this point, chip evacuation can become very difficult with an end mill, which will quickly wreck your tool and your part.

Z = final Z depth; position of Z-axis at the bottom of the hole (i.e. thickness of the part) + the radius of the drill diameter

Suitable for bench drill, hand drill and conventional electric drill. Perfect for wood, fiberboard, particleboard, plywood, plastic, PVC, rubber etc.

Mask offers large inhalation ports and a unique cartridge design to provide easy breathing. The exclusive corrugated exhale valve helps eliminate dead air, ...

Our DATRON Experts Help Many Customers Bring Manufacturing In-House. Reach Out To Our Team To See Which Machine And Accessories Are The Right Fit For Your Parts.

In observance of Thanksgiving, DATRON Dynamics will be closed on Thursday, November 28th, 2024. We will return to normal operations on Monday, December 2nd.

Support for CNC Copyright © by Lisa Hillyard is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

Break your chip – don’t try to be a hero and blast through your hole in one go, program a quick retract to get the chip out and let the coolant in.

With drilling, the same movement happens. The drill goes down. Chips need to be removed and/or broken; lubricant needs get inside the hole. The drill must be raised. The drill (or screw thread tool) goes up and down during holemaking operations.

Are you making a lot of holes? Drilling is probably the way to go. In most instances, a drill will best the fastest time you can achieve with an end mill.

Need to make a big hole? Big holes need big drills and lots of horsepower, this is where helical milling shines. Use an end mill that’s 60-80% the diameter of the hole you’re making to quickly clear out while leaving plenty of room for chips to escape.

Cobalt Drill Bits are considered one the best options for drilling into hardened steel materials. ... drill bits on offer, all suited for several types of ...

Need to make an extremely precise hole? While milling is typically perfectly acceptable, sometimes the tolerances require a drill and a reamer for the perfect finish.

Carbon fiber reinforced plastic ... Carbon fiber reinforced plastic (CFRP or CRP), is a very strong, light and expensive composite material or fiber-reinforced ...

Rapid prototyping? End mills will be appealing for their flexibility. Being adaptable to take on some features that may normally be drilled means you can spend less time CAMing a part and more time making chips.

Making lots of different size holes? Try to use the end mill, you’ll save time on tool changes and room in your tool changer.

Turn up the coolant – unless you have through tool coolant, you’re going to want to be sure to turn up the coolant flow and decrease your air pressure. The coolant needs to be able to flow into the hole during your retract. Learn more about DATRON tooling

If you’re making a very small hole, say, less than 1.5mm in diameter, go with a drill. End mills under 1.5mm become increasingly fragile, and subsequently cannot be run as aggressively, as a drill can be.

J = Amount to reduce cutting depth of each pass; peck depth reduction. The value reduces the following pecks by this amount.

Discover Tungaloy and the latest innovations in cutting tools and carbide inserts for turning, grooving, threading, drilling and milling applications.

In observance of Christmas, DATRON Dynamics will be closed on Tuesday, December 24th, 2024. We will return to normal operations on Thursday, December 26th.

0086-813-8127573

0086-813-8127573