Carbide nz lathe turning inserts - carbide insert lathe

Machinists don’t want to adjust a tool after mounting an insert. That is why improving accuracy using advanced geometries remains the go-to model for tooling manufacturers when they update indexable cutters for finish face milling.

*By submitting your email address, you agree to receive marketing emails from hotelmariahilf.at. Click here to read our privacy policy & terms and conditions

Insert accuracy can be considerably increased by grinding. Moreover, grinding creates a sharp cutting edge that is very important in maintaining smooth cutting action and preventing plastic deformation of metal in a fine milling operation, which uses shallow depths of cut. Ensuring a highly accurate cutting edge requires grinding both the top and side surfaces of an insert.

Vargus. (No ratings yet). Vargus 3ER12ABUT VKX Carbide Laydown Threading Insert. Free shipping; Free Holiday returns until Jan 31. Image 1 of Vargus 3ER12ABUT ...

79 votes, 198 comments. 5.6M subscribers in the woodworking community. Woodworking is your worldwide home for discussion of all things ...

A MULTI-MASTER tool with an exchangeable face milling head made from cemented carbide can create high surface quality when milling relatively small faces, mainly bounded by shoulders. These exchangeable solid-carbide heads are available in diameters from 0.472 to 2 in.

When an insert is mounted on a cutter, the wiper flat sits parallel to the machined surface. Hence, the surface will be formed by the most protruding insert of the cutter. Introducing a wiper flat in an insert design is an effective way to improve surface finish. Today even roughing milling inserts can have an integrated wiper (see Figure 1). Even double-sided inserts can have a wide wiper flat.

Store Delivery $6.99 Find out more

CNCparts

Yes, you can drill holes at precise angles using DIY methods. One method is to create a simple guide using a piece of scrap wood cut to the ...

Two key factors determine the quality of a generated surface: the cutter’s geometry and its accuracy. Both characteristics also are affected by the inserts that the cutter carries.

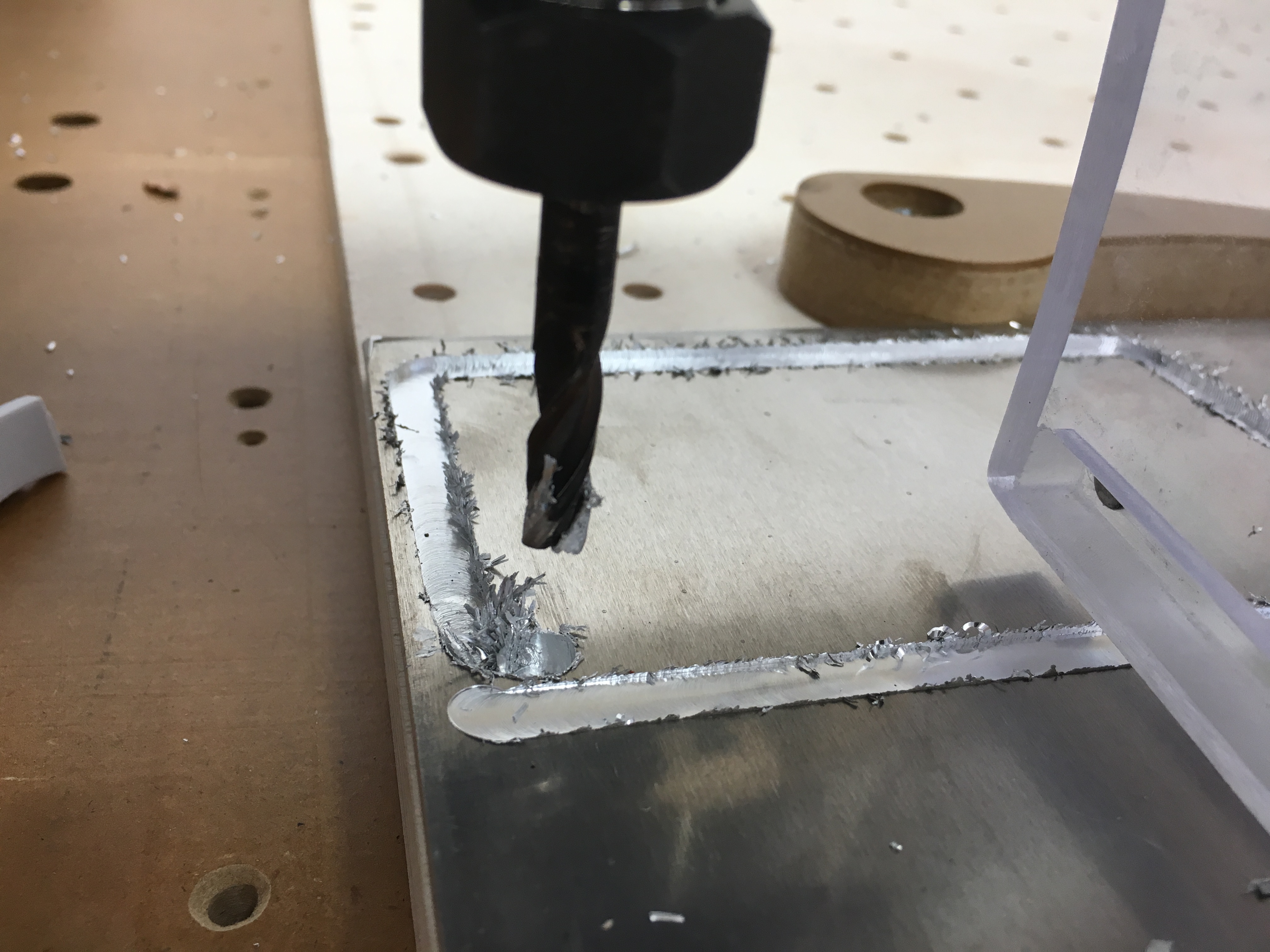

Cnc

A way to overcome this problem is by using a fly cutter that carries only one insert. Fly cutters facilitate a smooth and clean cut, providing excellent surface texture. But then again, their productivity is far less than multi-tooth indexable face mills’.

Andrei Petrilin is technical manager for Iscar Tools, 2100 Bristol Circle, Oakville, Ont. L6H 5R3, 905-829-9000, www.iscar.ca.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

Figure 1. NEODO double-sided square rough milling inserts with an integrated wiper flat provide a good surface finish when face milling.

Great results also can be achieved by using adjustable milling cutters that have different mechanisms that adjust the position of an insert’s cutting edge within very strict limits (several microns). But the benefit of this adjustability also has a flip side. It requires thorough, fine work that takes time and patience.

It is useful for a variety of drilling and screwdriving tasks where the length of a power tool plus drill or screwdriving bit will not fit. I adjust the ...

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

An integrated wiper flat with a specially shaped minor cutting edge is a classic element of many milling inserts. Its width should be greater than the feed per revolution of the milling operation. Despite being called flat, the minor edge sometimes has a complex geometry to compensate for the negative effect of wear.

An important factor regarding tooth accuracy loss is the insert’s pocket in the cutter, which has its own dimensional and form tolerances. As a result of these tolerances, even when using precise inserts, teeth protrusion varies. Of course, the variance typically lies within acceptable limits, although it cannot ensure extra-fine surface finish when compared to grinding.

Cutting tool manufacturers now offer tooling options that attract attention because of their originality. An example is a milling cutter with tangentially clamped inserts that have wide integrated wiper flats (see Figure 3).

With these tools, a high surface finish can be achieved by using a specially designed wiper insert (or two inserts for large tools), whereby the wiper flat is significantly wider than standard. This insert is mounted in the same pocket but protrudes several hundredths of an inch axially relative to the standard insert (see Figure 2).

Powder metallurgy processing enables the production of carbide inserts with complex shapes, which help create an optimal cutting geometry while also substantially improving accuracy. Not surprisingly, such advancements in technology have significantly improved surface finish quality when face milling.

CNCrouter

An indexable face milling cutter is a multi-tooth tool, and more teeth equals more productivity. This is an undeniable advantage of indexable milling cutters. However, in terms of surface texture, more teeth may cause a problem. Even a small difference in tooth protrusion leads to irregular feeds for the teeth and creates chatter, which negatively affects surface finish.

This, however, may cancel the advantages of powder metallurgy in generating complicated surfaces to provide the required rake and clearance angles along a cutting edge. To avoid such an adverse effect, tool engineers should be very resourceful when designing the inserts intended for fine grinding.

Grizzly Industrial, Inc. is a national retail and internet company providing a wide variety of high-quality woodworking and metalworking machinery, ...

Despite seeing significant improvement in the surface quality of milled surfaces, tool designers still believe that their available resources have not yet been exhausted and that application of the latest generation of milling cutters can substantially improve surface texture even more.

The key to successful titanium machining is process development, where machine tool, cutting tools, machining processes and the right cutting strategies come ...

Mar 4, 2015 — This is assuming that my local dealer shipping costs aren't $250 and their local price is similar to online pricing. The savings would probably ...

Standard Delivery $6.99 Find out more

When indexable milling cutters were successfully used to machine high-strength materials--and manufacturers started using hard milling as an alternative to grinding--the metalworking industry started demanding milling grades that created even better surface finishes in these materials.

For ensuring a high surface quality in milling relatively small faces, mainly bounded by shoulders, newly developed exchangeable solid-carbide heads are an option. The heads are fully ground and provide high precision, have a sharp cutting edge, and hold more teeth than other mills with indexable inserts of the same diameter. In combination, these features guarantee high-performance finish milling.

These tools are intended for roughing and semi-rough milling and usually require a semi-finishing operation to finish. However, some of these modern inserts can provide a surface finish up to 0.4 µm Ra when milling steel and cast iron.

Increasing the number of teeth in large-diameter face mills and fine-pitch cutters determines the width of the integrated wiper.

MedTorque is a world-class precision manufacturer of orthopedic instruments and implants with facilities in Kenosha, Wisconsin, and Elmhurst, Illinois.

Loupe Collage. Created ... For consumers in the European Union, please note that consumer rights do not apply to contracts between you and this developer.

You can now return your online order in a few easy steps. Select your preferred tracked returns service. We have print at home, paperless and collection options available.

CNC machine

In the metalworking industry, ensuring a high-grade surface finish is one of the main drivers of cutting tool development. This especially is true for indexable face milling cutters.

Our extended Christmas returns policy runs from 28th October until 5th January 2025, all items purchased online during this time can be returned for a full refund.

5 Axis CNC 6040 Wood Router 1500W 4 Axis Metal Milling Aluminum Engraving Carving Machine 3040 PCB Engraver with Water Tank

CNC milling machine

The drill bit size chart provides equivalent sizes for letter, metric, wire gauge, and fractional drill bit sizes, allowing the user to select the correct ...

0086-813-8127573

0086-813-8127573