Carbide Parting & Grooving Inserts - grooving insert nomenclature

Example 3: Calculate the speed and feed for a HSS countersink used to countersink a #10 clearance hole in aluminum using a manual milling machine.

* multiply feed values in table by 0.5 for difficult to machine materials, flexible toolholding or workpieces, or lighter-duty machines*

Feedrate formula for milling

The microstructure of stainless steel, such as grain size and phase composition, has a significant effect on its hardness. Refining grains and optimizing phase composition are effective ways to improve the hardness of stainless steel.

TIP2: When drilling deeper holes (> 3xD) without high pressure TSC (thru spindle coolant), reduce spindle speed an additional 50%.

Feedrate unit

The hardest grade of stainless steel is often considered to be 440C, a martensitic stainless steel. It can achieve a hardness of around 58 to 62 HRC (Rockwell C) after proper heat treatment. Other hard stainless steel grades include 420 and AISI 630, but 440C is typically recognized for its superior hardness and wear resistance, making it suitable for applications like knives and other cutting tools.

First, lookup the recommended surface speeds in Table 1 (VALUM ≈ 625 ft/min, VSTEEL ≈ 250 ft/min (notice the 2.5 multiplier))

Aluminum: Typically softer than stainless steel, with hardness values depending on the alloy. For example, common alloys like 6061 have a hardness of about 60 to 70 HRB, while harder alloys like 7075 can reach around 90 HRB.

Example 2A: Calculate the speed and feed for a 1″ diameter, 4 flute HSS endmill in aluminum using a manual milling machine in lab.

Note that these speed and feed values are guidelines assuming adequate (flooded) lubrication, workpiece stiffness and drill depth less than 3 drill diameters (0.75″). When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 900 rpm and f = 3.6 in/min (final answer).

In stainless steel, the chromium, nickel and molybdenum content affects its hardness and corrosion resistance. More carbon increases the hardness, but decreases the corrosion resistance.

Note: since applying oil manually, scale the speeds back to 60%, so NALUM ≈ 1425 rpm and NSTEEL ≈ 570 rpm (final answer). Note these are MAXIMUM values and lathe chuck safety must take precedence; spinning the lathe chuck at 570 rpm is about the upper limit of what we safely do in the lab, so for smaller or easier to machine workpieces, DO NOT EXCEED 600 RPM regardless of the calculation results, unless you are running a collet chuck.

The hardness of 304 stainless steel typically ranges from 70 to 90 HRB (Rockwell B) in its annealed condition. Similar to 316 stainless steel, if 304 stainless steel undergoes cold working or other processes, its hardness can increase, potentially reaching about 30 to 40 HRC (Rockwell C). The exact hardness can vary based on specific processing methods and conditions.

What is feed in machiningformula

Stainless steel is not always hard steel. Although some types of stainless steel, such as martensitic stainless steel, can reach very high hardness with proper heat treatment, most stainless steel, such as austenitic stainless steel, are usually lower in hardness and more focused on corrosion resistance. Hard steel usually refers to high carbon steel or alloy tool steel, which has much higher hardness and strength than most stainless steel.

Stainless steel and carbon steel have certain differences in hardness, which mainly stem from their different chemical composition and microstructure.

Next, calculate the feed rate used for plunging. Remember annular cutters should be fed at approximately 25% of the feedrate for an equivalent sized endmill. From Table 3, lookup the recommended feed per tooth for a 1″ HSS endmill (ft ≈ 0.008 in/tooth) and calculate the plunge feed rate using Equation 3:

By accurately controlling parameters such as quenching temperature, holding time and cooling rate, the ideal microstructure and hardness can be obtained. At the same time, a reasonable tempering treatment can maintain a certain hardness while increasing the toughness of the material.

Every metal cutting operation requires selection of proper cutting parameters for success. As a DML TA, you need to understand basic calculations that will allow the tools you use to work as intended.

Cuttingfeeddefinition

TIP: Reamers should generally be run at half the spindle speed and twice the feed per revolution of the equivalent sized drill bit.

Application field: Due to its excellent corrosion resistance and good mechanical properties, stainless steel has been widely used in occasions where corrosion resistance and hardness need to be considered at the same time (such as chemical equipment, food processing machinery, etc.). Carbon steel is more common in situations where corrosion resistance is not a particular concern (such as building structures, bridges, etc.) because of its low cost and good processing performance.

The following are the typical hardness values of some common stainless steel types. Please note that the specific hardness values may vary due to different material processing and heat treatment processes. They are for reference only. In actual applications, it is recommended to determine them based on the test results of specific materials.

First, lookup the recommended surface speed in Table 1 for a 1 HSS endmill cutting aluminum (V ≈ 250 ft/min) and calculate the spindle speed from Equation 2 using the aforementioned 75% speed reduction:

First, lookup the recommended surface speed in Table 1 (V ≈ 100 ft/min) and calculate the spindle speed from Equation 2:

The hardness of 420 stainless steel typically ranges from 50 to 60 HRC (Rockwell C) after heat treatment. In its annealed condition, it generally has a hardness of around 30 to 40 HRC. The exact hardness can vary based on specific processing and heat treatment methods.

TIP: Plunging should generally be performed at 75% of the speed and 25% of the feedrate of the calculated peripheral cutting parameters.

Hardness range: Carbon steels have a wide range of hardness, from low to high. Stainless steels have varying hardnesses, from low for austenite to high for martensite and precipitation hardening.

Please begin by reviewing the comprehensive course document on this topic, as it clearly explains the process of calculating these parameters for drilling and milling operations. The governing equations are summarized below.

Cold working such as cold rolling and cold drawing will cause stainless steel to produce work hardening, that is, as the amount of deformation increases, the hardness gradually increases. However, excessive cold working may result in the material becoming brittle and impacting its properties.

Next lookup the recommended feed per revolution for the drill bit in Table 2 (fr ≈ 0.004 in/rev) and calculate the feed rate using Equation 3:

Note: when applying oil manually, scale the feed and speed back to 60%, so N ≈ 420 rpm and f ≈ 4.8 in/min (final answer). This is close enough to 500 rpm that I would first try this tool at the low end of high range with good oil application and see how it goes.

TIP: When working with plastics with good machinability, use the cutting parameters for aluminum up until the point that the plastic melts.

Chemical composition: Carbon steel consists mainly of iron and carbon and may contain a few alloying elements to improve properties. In addition to iron and carbon, stainless steel also adds alloying elements such as chromium and nickel, which have an important influence on the corrosion resistance and hardness of stainless steel.

What is feed in machiningcnc

Note that these speed and feed values are guidelines assuming proper (flooded) lubrication, workpiece stiffness and depth of cut. When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 570 rpm and f ≈ 18 in/min (final answer). Note also this problem assumes we peripheral milling versus plunge milling (since we never teach the students the latter in lab).

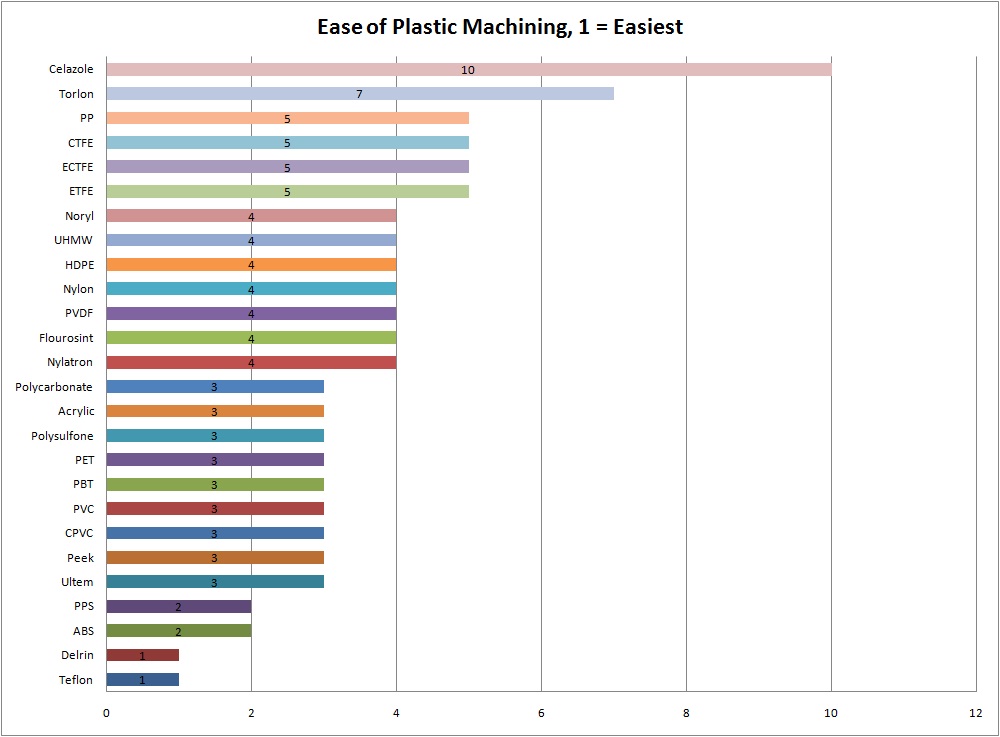

As you can see Acetal (Delrin) is one of the most machinable plastics and nylon is four times less machinable (which is why it should usually be avoided!).

What is feed inlathe machine

Note that these speed and feed values are guidelines assuming proper (flooded) lubrication, workpiece stiffness and depth of cut. When learning how to use the CNC, always start lower (around 60% on the spindle speed and feedrate override buttons) and work your way up as you gain confidence or purchase your own tools (lol).

First, lookup the recommended surface speed in Table 1 (V ≈ 250 ft/min) and calculate the spindle speed from Equation 2:

Hardness is the ability of a material to resist local pressure deformation or scratching. It is not inherent in the material and is affected by the test method and conditions. Measuring hardness is crucial to evaluating the wear resistance, processing performance and life of the material. For stainless steel, hardness is directly related to its application breadth and durability.

TIP2: Do not plunge an annular cutter at a feedrate less than 0.001 ipt (inch per tooth) in strain hardening materials like 304 stainless or titanium.

There are many ways to improve the hardness of stainless steel, mainly including adjusting the chemical composition, optimizing the heat treatment process, increasing the degree of cold processing, and using surface treatment technology.

Feedrate formula

A general rule of thumb for materials which are strong enough to support the drilling process is that fr is between 1 - 3% of the drill diameter, depending on the material strength.

Mohs hardness is a relative hardness test method that compares the material’s ability to resist scratching. It is divided into ten levels, with level 1 being the softest, such as talc, and level 10 being the hardest, such as diamond. This test is simple but highly subjective and is not suitable for accurately measuring the hardness of metals such as stainless steel.

The hardness of 316 stainless steel typically ranges from 70 to 90 HRB (Rockwell B) in its annealed condition. When subjected to cold working or other processes, its hardness can increase, reaching about 30 to 40 HRC (Rockwell C). The exact hardness can vary based on specific processing methods and the material’s condition.

The hardness of 304 stainless steel, also known as 18-8 stainless steel due to its composition of approximately 18% chromium and 8% nickel, typically ranges from 70 to 90 HRB (Rockwell B) in its annealed condition. If cold worked, the hardness can increase to about 30 to 40 HRC (Rockwell C). The specific hardness can vary based on processing methods and the condition of the material.

Next, lookup the recommended feed per tooth (chipload) in Table 3 (ft ≈ 0.004 in/tooth) and calculate the feed rate using Equation 3:

The microstructure of stainless steel can be changed by heat treatment methods such as quenching and tempering, thereby affecting its hardness. Quenching can significantly increase the hardness of stainless steel, but it is easy to increase brittleness; tempering can improve the toughness of the material while maintaining a certain hardness.

Example 2B: Calculate the speed and feed for a 1/2″ diameter, 3 flute carbide endmill if peripheral and plunge cutting in aluminum using a CNC milling machine in lab.

Such as carburizing, nitriding, surface hardening treatment, etc., can significantly improve the hardness and wear resistance of the material surface without changing the performance of the stainless steel matrix.

TIP: Countersinking should generally be performed at 25% of the speed and the same feed per revolution as the equivalent sized drill.

Example 4: Calculate the speed and feed for a 1″ diameter, 6 flute HSS annular cutter in ¼ thick aluminum on a manual milling machine in the lab.

Next, lookup the recommended feed per tooth (chipload) in Table 3 (ft ≈ 0.008 in/tooth) and calculate the feed rate using Equation 3:

The table below contains a recommended surface speeds for common materials when using DML equipment. These values are conservative because our primary goal is fostering a safe learning environment (for our users and our tools!), not trying to squeeze every second out of each operation.

Next lookup the recommended feed per revolution for the equivalent size drill bit in Table 2 (fr ≈ 0.006 in/rev) and calculate the feed rate using Equation 3:

What is feedrate

TIP1: Recommended peck depth when drilling less than 3xD (e.g. 3 drill diameters) with flooded coolant is one drill diameter, or when applying oil manually, or under low pressure, is 50% of drill diameter.

Stainless Steel: Generally has a higher hardness compared to aluminum. Common grades like 304 and 316 typically range from 70 to 90 HRB (Rockwell B) in their annealed condition, while martensitic grades like 420 and 440C can achieve 50 to 65 HRC (Rockwell C) after heat treatment.

The hardness of stainless steel has an important influence on its performance in practical applications. Materials with high hardness usually have better wear resistance and scratch resistance, and are suitable for occasions requiring high wear resistance, such as tools, bearings, molds, etc. Stainless steel with lower hardness has better ductility and machinability, and is suitable for occasions requiring forming processing, such as pipes, containers, etc.

Rockwell hardness test is widely used for a variety of materials. The diamond cone indenter is used to lightly press the surface of the material, and the depth of the indentation is measured to obtain the hardness. There are HRA, HRB, HRC and other scales. The HRC scale is commonly used for stainless steel. The larger the HRC value, the harder the material.

Note that these speed and feed values are guidelines assuming adequate (flooded) lubrication and workpiece stiffness. When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 330 rpm and f = 2.0 in/min (final answer).

Example 5: Calculate the speeds for parting off 1 diameter aluminum and 1 diameter mild steel workpieces on the lathe using the standard carbide part-off inserts.

First, lookup the recommended surface speed in Table 1 (V ≈ 625 ft/min) and calculate the spindle speed from Equation 2:

SteelPRO Group provides you with quality products and services. We can produce a variety of stainless steels that meet your various hardness requirements. If you need to purchase or customize, please feel free to contact us.

As an important indicator of material ability, hardness is crucial for the performance evaluation and application selection of stainless steel. We explain in detail the concept, measurement method, influencing factors, significance and methods of improving the hardness of stainless steel, and compare it with carbon steel so that you can better understand stainless steel. Finally, a stainless steel hardness table is attached for reference.

Note that these speed and feed values are guidelines assuming adequate (flooded) lubrication, workpiece stiffness and drill depth less than 3 drill diameters (0.75″). When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 450 rpm and f = 3.6 in/min (final answer).

The Brinell hardness test is a commonly used hardness assessment method suitable for softer materials. It calculates the hardness by the size of the indentation left by a steel ball when it is pressed into the material. It is expressed in HB, and the larger the value, the harder the material. However, due to its large indentation, it is not suitable for measuring thin plates or small parts.

Through cold processing methods such as cold rolling and cold drawing, stainless steel is hardened, thereby increasing its hardness. However, it is necessary to control the processing volume to avoid excessive processing that causes the material to become brittle.

TIP: IF this was being performed on a CNC lathe, typical parting feed rates vary between 0.001 in/rev (for steels) and 0.005 in/rev (for plastics). But remember, do NOT use the power feed when parting on a manual lathe unless you own the machine!

First, lookup the recommended surface speed in Table 1 (V ≈ 250 ft/min) and calculate the spindle speed from Equation 2:

Vickers hardness (HV) is a common technique for evaluating the hardness of metals (such as stainless steel) and non-metallic materials. A diamond square cone indenter is used to apply a load to the material, and the hardness is quantified by measuring the diagonal length of the tiny indentation. The smaller the indentation, the harder the material. This technique is known for its high precision, small indentation and good repeatability, but it is necessary to ensure that the sample is flat and the test conditions are stable to ensure accurate results.

The hardness of stainless steel is affected by many factors, mainly including chemical composition, heat treatment process, degree of cold working and microstructure.

TIP1: Since annular cutting is a plunging operation, it should generally be performed at 75% of the speed and 25% of the feedrate of the calculated peripheral cutting parameters (as with endmill plunging).

Huai Steel New Material Tech Co., LTDHua Hua Road, Qingjiangpu District, Huai an CityJiangsu Province, China+86 517-3346-7823

Hardness also affects the cutting performance of the material. High-hardness materials are prone to wear of the tool during cutting, but the quality of the machined surface is better. For parts that require higher processing accuracy, appropriate hardness is necessary.

The hardness of stainless steel can be improved by increasing the carbon content, adding alloying elements (such as molybdenum, vanadium, etc.) or using special alloying technology. However, attention should be paid to the fact that increasing the carbon content may reduce the corrosion resistance of the material.

0086-813-8127573

0086-813-8127573