Carbide Tipped Locksmith Drills - carbide drill bits for hardened steel

ANSI B94.11M-1979 sets size standards for jobber-length straight-shank twist drill bits from 1/64 inch through 1 inch in 1/64 inch increments. For Morse taper-shank drill bits, the standard continues in 1/64 inch increments up to 1¾ inch, then 1/32 inch increments up to 2¼ inch, 1/16 inch increments up to 3 inches, 1/8 inch increments up to 3¼ inches, and a single 1/4 inch increment to 3½ inches. One aspect of this method of sizing is that the size increment between drill bits becomes larger as bit sizes get smaller: 100% for the step from 1/64 to 1/32, but a much smaller percentage between 1 47/64 and 1 3/4.

With plastics that are thicker than ¼ inches (such as plastic skirting, plastic piping, and Perspex sheeting), the best equipment is a saw. For precise and smoothest plastic cutting, a fine-toothed saw works most effectively. It also serves you well when you need to make several non-linear cuts. If you want to cut thicker plastic items, like pipes, a jigsaw works great. However, it might not provide you with precise results. Larger plastic pipes or thick plastic blocks are easily cut using a table saw. Remember to use a non-melting blade with caution.

Plastics are one of the most commonly used materials in many industries. Manufacturers always require an effective plastic cutting tool to get their job done with high accuracy and zero damage. Since there are various plastic cutting tools in the market to work with different types of plastics, choosing the right option seems complicated. This article will help you find out with tips to simplify the process. Let's follow along! Read more: What is plastic? Everything you need to know about plastic

Metric dimensioning is routinely used for drill bits of all types, although the details of BS 328 apply only to twist drill bits. For example, a set of Forstner bits may contain 10, 15, 20, 25 and 30 mm diameter cutters.

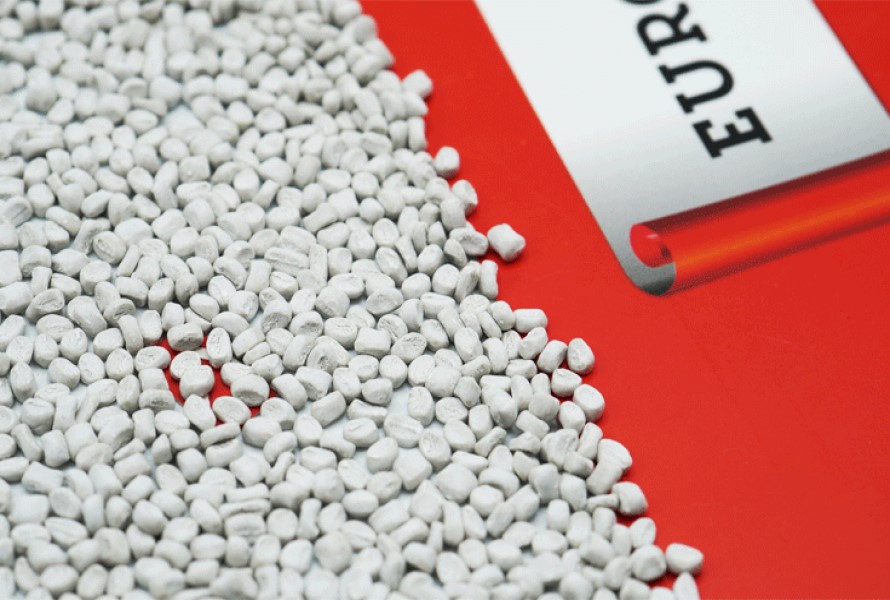

Color masterbatch from EuroPlas is a solution for end-product aesthetics. It's made from high-quality pigments, carrier resin, and some special additives, creating a colorful and attractive appearance. EuroPlas provides a wide range of colors and effects, from simple to complicated, of color masterbatch.

The gauge-to-diameter ratio is not defined by a formula; it is based on—but is not identical to—the Stubs Steel Wire Gauge, which originated in Britain during the 19th century.[2] The accompanying graph illustrates the change in diameter with change in gauge, as well as the reduction in step size as the gauge size decreases. Each step along the horizontal axis is one gauge size.

For machining purposes, plastic material can be broadly divided into two categories: soft and hard. Single or double-edge "O" flute tools, which come in straight or spiral shapes, are needed for soft plastic material. Hard plastic calls for spiral "O" flutes with hard plastic geometry and double-edge "V" flute tools. It is advised to use three-edge finishers. For manual operations, high-speed steel and solid carbide are easily obtainable as tool materials for the majority of these router bits, which are CNC machinable.

In the U.S., fractional inch and gauge drill bit sizes are in common use. In nearly all other countries, metric drill bit sizes are most common, and all others are anachronisms or are reserved for dealing with designs from the US. The British Standards on replacing gauge size drill bits with metric sizes in the UK was first published in 1959. [citation needed]

Besides the help to meet color requirements, the material saves time and cost as manufacturers can use it directly in the production process. Plus, it causes no harm to the environment.

Over-clamping can lead to breakage and deformation since plastics are softer and more flexible than metals. Thus, it's better to use soft jaws or fixtures to avoid scratching the surface.

Number and letter gauge drill bits are still in common use in the U.S. and to a lesser extent the UK, where they have largely been supplanted by metric sizes. Other countries that formerly used the number series have for the most part also abandoned these in favour of metric sizes.[citation needed]

Below is a chart providing the decimal-fraction equivalents that are most relevant to fractional-inch drill bit sizes (that is, 0 to 1 by 64ths). (Decimal places for .25, .5, and .75 are shown to thousandths [.250, .500, .750], which is how machinists usually think about them ["two-fifty", "five hundred", "seven-fifty"]. Machinists generally truncate the decimals after thousandths; for example, a 27/64" drill bit may be referred to in shop-floor speech as a "four-twenty-one drill".)

The image shows a long-series drill compared to its diametric equivalents, all are 11⁄32 inch (8.7313 mm) in diameter. The equivalent Morse taper drill shown in the middle is of the usual length for a taper-shank drill. The lower drill bit is the jobber or parallel shank equivalent.

Plastic sheets, plastic packing, and plastic banding are a few examples of thin plastic. In this case, the most suitable plastic cutting tool is a utility knife, as it offers excellent control and grip. A utility knife functions similarly to scoring glass. Since the tool cuts a shallow incision in the plastic, making it easier to break the plastic or cut through it completely.

Using high spindle speeds and low feed rates is a good general rule of thumb when working with plastic to reduce the heat. You should modify feeds and speeds based on the chip formation. Ideally, the chips should be relatively small.

When some polymers are machined, harmful gases may be released. Always make sure there is enough ventilation, and use safety gear, such as masks and goggles.

EuroPlas engineering plastic compound is full-function-in-one-material to save time and production costs. The combination is made of resin, additives, and reinforcements (based on the end-product requirements).

The thing is that friction is needed for cutting, but it produces heat at the same time, causing the plastics to melt when heated. If your material gets melted a little bit, you'll have uneven and rough edges. If it melts too much, you'll face the process called "chip-weld," in which the material will re-bond behind the cutting tool. In both cases, your final products will not meet the quality and aesthetic requirements.

Long, stringy chips can appear on plastics, requiring regular chip cleaning to avoid entanglement and interfering with the cutting process.

Before getting to know the best plastic cutting tools, you should know which one you should not use to avoid poor cuts and dangerous situations. They include:

EuroPlas filler masterbatch combines calcium carbonate CaCO3, primary resin, and other plastic additives based on the customers' requirements. The products have many advantages, such as reduced shrinkage, improved stiffness, and bend strength, the capability to enhance stability, printability, and surface quality of the final products, and energy savings. It's ideal for injection molding, blow molding, PVC pipe manufacturing, packaging, plastic frames, door production, etc.

Keeping the incision shallow might also aid in avoiding heat accumulation. It is cooler to have two shallow passes than one deep pass.

The price and availability of particular size bits does not change uniformly across the size range. Bits at size increments of 1 mm are most commonly available, and lowest price. Sets of bits in 1 mm increments might be found on a market stall. In 0.5 mm increments, any hardware store. In 0.1 mm increments, any engineers' store. Sets are not commonly available in smaller size increments, except for drill bits below 1 mm diameter. Drill bits of the less routinely used sizes, such as 2.55 mm, would have to be ordered from a specialist drill bit supplier. This subsetting of standard sizes is in contrast to general practice with number gauge drill bits, where it is rare to find a set on the market which does not contain every gauge.

EuroPlas has a wide range of additives for plastic, such as Flame retardants, Desiccants, Odor removing additives, Anti-UV additives, Anti-aging additives, Anti-fog additives, Antistatic additives, Anti-blocking additives, and Processing-aid additives.

The shortest standard-length drills (that is, lowest length-to-diameter ratio) are screw-machine-length drills (sometimes abbreviated S/M). They are named for their use in screw machines. Their shorter flute length and shorter overall length compared to a standard jobber bit results in a more rigid drill bit, reducing deflection and breakage. They are rarely available in retail hardware stores or home centers.

Number drill bit gauge sizes range from size 80 (the smallest) to size 1 (the largest) followed by letter gauge size A (the smallest) to size Z (the largest). Although the ASME B94.11M twist drill standard, for example, lists sizes as small as size 97, sizes smaller than 80 are rarely encountered in practice.

Drill bits are the cutting tools of drilling machines. They can be made in any size to order, but standards organizations have defined sets of sizes that are produced routinely by drill bit manufacturers and stocked by distributors.

With more than 15 years of producing and exporting filler masterbatch to thousands of businesses around the world, EuroPlas is proud to offer a wide range of filler masterbatch to help manufacturers save cost, enhance productivity and produce high-quality plastic products.

Jobber-length drills are the most commonly found type of drill. The length of the flutes is between 9 and 14 times the diameter of the drill, depending on the drill size. So a 1/2 in (12.7 mm) diameter drill will be able to drill a hole 4+1/2 in (114.3 mm) deep, since it is 9 times the diameter in length. A 1/8 in (3.175 mm) diameter drill can drill a hole 1+5/8 in (41.275 mm) deep, since it is 13 times the diameter in flute length.[3]

Fractional-inch drill bit sizes are still in common use in the United States and in any factory (around the globe) that makes inch-sized products for the U.S. market.

The possibility of plastic chipping while cutting increases with its hardness. In case of chipping, try to have more teeth on each blade. Reduce the number of teeth, though, if the material begins to exhibit indications of glazing or overheating. Soft plastics, as previously said, require fewer teeth.

EuroPlas is known as a leader in the masterbatch field since the company satisfies a wide range of requirements for unique plastic raw material solutions to optimize production costs and improve the competitiveness of the customers. Here is the list of outstanding products from EuroPlas:

Extended-reach or long-series drills are commonly called aircraft-length from their original use in manufacturing riveted aluminum aircraft. For bits thicker than a minimum size such as 1⁄8-inch (3.175 mm), they are available in fixed lengths such as 6, 8, 12 or 18 inches (152, 203, 305 or 457 mm) rather than the progressive lengths of jobber drills.

BioNEXT, a bio compound exclusively developed by EuroPlas, can be decomposable within 12 months after use. The company guarantees that the end product passes strict quality control management to meet all the requirements. Contact EuroPlas right now for the best price of all products!

The term jobber refers to a wholesale distributor—a person or company that buys from manufacturers and sells to retailers.[citation needed] Manufacturers producing drill bits "for the trade" (as opposed to for specialized machining applications with particular length and design requirements) made ones of medium length suitable for a wide variety of jobs, because that was the type most desirable for general distribution. Thus, at the time that the name of jobber-length drill bits became common, it reflected the same concept that names like general-purpose and multipurpose reflect.[citation needed]

All EuroPlas products are various, including PA6, PA66 blend compound, PBT GF-FR compound, ABS Glass fiber compound, ABS Antistatic compound, PC flame retardant compound, and ABS. All are of high quality and flexibility. If you're looking for a material for automobile, electronics manufacturing, interior decoration, and renewable energy, you should not miss these products from EuroPlas.

Drill bit sizes are written as irreducible fractions. So, instead of 78/64 inch, or 1 14/64 inch, the size is noted as 1 7/32 inch.

Number and letter sizes are commonly used for twist drill bits rather than other drill forms, as the range encompasses the sizes for which twist drill bits are most often used.

Plastic additives are a necessary substance used in the production process to improve the material's performance. Besides, they help the plastic become more durable, thanks to the enhanced chemical and physical resistance.

Center drills are available with two different included angles; 60 degrees is the standard for drilling centre holes (for example for subsequent centre support in the lathe), but 90 degrees is also common and used when locating holes prior to drilling with twist drills. Center drills are made specifically for drilling lathe centers, but are often used as spotting drills because of their radial stiffness.

If our final products require a smooth surface, using a finishing pass with a fine tool and a slower feed rate is highly recommended.

In smaller sizes, bits are available in smaller diameter increments. This reflects both the smaller drilled hole diameter tolerance possible on smaller holes and the wishes of designers to have drill bit sizes available within at most 10% of an arbitrary hole size.

Metric drill bit sizes define the diameter of the bit in terms of standard metric lengths. Standards organizations define sets of sizes that are conventionally manufactured and stocked. For example, British Standard BS 328 defines 230 sizes from 0.2 mm to 25.0 mm.

Spotting drills are available in a relatively small range of sizes, both metric and imperial, as their purpose is to provide a precise spot for guiding a standard twist drill. Commonly available sizes are 1/8", 1/4", 3/8", 1/2", 5/8", 3/4", 4 mm, 6 mm, 8 mm, 10 mm, 12 mm, 14 mm, 16 mm and 18 mm. The drills are most ordinarily available with either 90° or 120° included angle points.

Thinner plastics are easier to chip than harder ones. As a result, the rake angle should be lowered, and the blade will need more teeth. Plus, the sharp top bevel angles may be necessary, especially when dealing with very soft or paper-thin polymers.

Hard plastics include both thin and thick types, but the term "hard" refers to the plastic's brittleness. Plastic toys and pegs are two examples of hard plastic. Using the incorrect tools for cutting brittle, hard plastic might cause the edge to break or fracture. The best hard plastic cutting tools are a saw or a piece of string, depending on the size, direction, and precision of the cut. A saw: A jigsaw, hand saw, and table saw are perfect for cutting thick, hard plastics. It's highly recommended to choose a blade with a high tooth count for a smoother cut. A piece of string: It's an ideal option for cutting small pieces of hard plastic, including hand-made plastic toys or other hard plastic craft goods.

Many polymers can be machined dry. However, with a coolant or air blast, you can avoid melting some plastics and enhance their surface quality. Make sure the coolants you use are appropriate for the plastic. Certain polymers may absorb the coolant, which might cause deterioration or changes in dimensionality.

As a professional, EuroPlas understands the industry's ongoing trend and demand for green, biodegradable plastic. And the company is also concerned about sustainable development and the environment; thus, a list of high-quality EuroPlas bioplastic compounds is produced to be used in various aspects, including automotive & transport, construction, fibers, electronics, household appliances, and especially food packaging.

0086-813-8127573

0086-813-8127573