carbon is allowed to diffuse through a steel plate 10 ... - carbon is allowed to diffuse through a steel

End Mill sizes

This has been a look into the basic types of end mills. These small tools are very complex when you look closely at their design. Using end mills, and the milling process in general, is a unique way of cutting and altering metal and other working materials. And with so many varieties of these cutting tools to choose from, there is an option for almost any material or job you present. If you are interested in looking into the different types of end mill further, check out the selection at Penn Tool Co. We supply a variety of cuts, styles, and sizes to meet your milling needs.

End mill geometry PDF

End mills are metal work cutting tools that can create shapes, holes, and shave down a working material for milling and a variety of other applications. These other processes include profiling, contouring, reaming, drilling, and more. These cutting tools feature carved, sharp edges at their tip and along their circumference. These edges allow them to carve out the face and sides of your milling material. End mills are specifically designed to be able to cut on an axis, which sets them apart from other milling bits. And while some specifically designed end mills can drill into a surface, make sure not to confuse them with drill bits.

End mill nomenclature

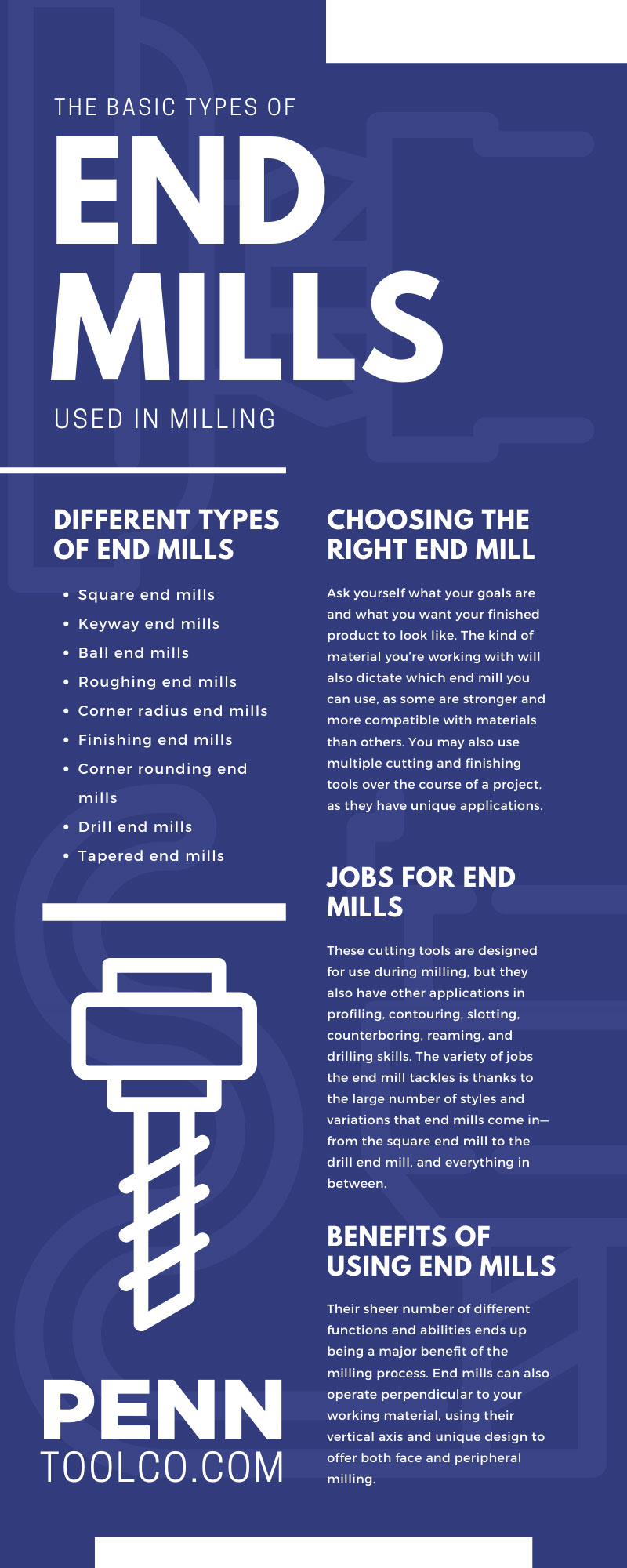

These cutting tools are designed for use during milling, but they also have other applications in profiling, contouring, slotting, counterboring, reaming, and drilling skills. The variety of jobs the end mill tackles is thanks to the large number of styles and variations that end mills come in—from the square end mill to the drill end mill, and everything in between. Whether you need to shave off excess material on a piece, grind away or deburr an imperfection, or create a nice finish, there is an end mill for many of these common metalworking needs.

Drill bits and end mills excel in different areas. While you can use an end mill for shallow drilling jobs, any depth more than four times the diameter is a job for a drill bit. A drill bit is designed to make deep holes down into your working material, while an end mill is designed for cutting away at the sides and face of the material. You can tell end mills from drill bits by the flutes they possess. Flutes are the grooves that are carved into the end mill. Based on this variety and their multi-angle design, end mills are more versatile than drill bits.

Ball Nose End Mill

When you’re dealing with hardened steel, ordinary drill bits just won’t cut it. You need drill bits designed specifically for this challenging material. Here’s what to look for:

End mill cutter drawing

End mill Cutter sizes in mm

Are you familiar with end mills for metalworking? These parts may look like drill bits, but they are quite different—they are used in a process called milling. Milling is a unique kind of metal cutting process that stresses accuracy and makes precision cuts in a working material. This is where ends mills come in. End mills are the extensions that make these details and cuts to a piece of metal. Before we break down the basic types of end mills, let’s start this deep dive by understanding milling as a metalworking process.

When it comes to drilling through tough and sturdy materials like metal, having the right drill bits is crucial. Whether you’re a professional tradesperson or a DIY enthusiast, selecting the best drill bits for metal can make all the difference in the success of your project. In this comprehensive guide, we will explore the top options available, including cobalt drill bits and heavy-duty variants designed for hardened steel.

Before we dive into the specific types of drill bits, it’s essential to understand the key factors that make a drill bit suitable for metalworking.

Drill Bits USA has been serving customers for over 16 years and has over 30 years of experience. Put your trust in a company that has the knowledge and expertise to help you find exactly what you need to complete your job.

Milling is a machining process that removes mass from your working piece of metal or other manufacturing material. Milling machines use rotary cutters, which contact this working material and shave away bits of metal as it advances. Milling processes are some of the most customizable in all metal machining, as you can vary the pressure of the contact, direction, axis, and switch out cutting heads when needed. Because it offers so much customization and control, milling is one of the best ways to perform precise cutting jobs. Milling has two major categories: face milling and peripheral milling. Face milling cuts flat surfaces across the top or bottom of your workpiece, while peripheral milling carves out material using the outside circumference of the cutting tool. One of the types of cutters used here is the end mill.

Their sheer number of different functions and abilities ends up being a major benefit of the milling process. End mills can also operate perpendicular to your working material, using their vertical axis and unique design to offer both face and peripheral milling. These unique parts are also great for making small, precise cuts, which is a great application for your more intricate metalworking jobs. This is how these tools help improve your milling production, as well as your general metalworking production.

The material that your cutting tools are made of can also set them apart. Materials like steel, cobalt, carbide, and even diamond are common materials that make up end mills. The harder the working material, the harder the cutting tool you would need, all the way up to diamond strength.

End mill cutter specification

Cobalt drill bits are the go-to choice when you need to tackle tough metal surfaces. Here are some reasons why cobalt drill bits stand out:

End mill diagram

For heavy-duty metalworking tasks, such as drilling into thick metal plates or structural steel, you’ll need heavy-duty drill bits that can handle the load. Here’s what sets them apart:

The number of flutes, or grooves, is also a classification for types of end mills. They can feature single-flute designs or multiple flutes. Single-flute designs help carve out large amounts of material during the milling process. The more flutes you add, the less efficient the material removal, though they also produce a finer finish.

Selecting the right drill bits for metal is essential for achieving precise and efficient results in your metalworking projects. Whether you opt for cobalt drill bits, specialized bits for hardened steel, or heavy-duty variants, always prioritize quality and compatibility with your specific drilling needs. With the best drill bits at your disposal, you’ll be well-equipped to tackle any metal drilling task that comes your way.

Each of these types of end mill has a different characteristic that makes it ideal for a specific job. For example, square end mills have a multi-purpose design for use in general milling applications. Contrast that with roughing end mills, which are more specific in their uses. Roughing end mills are designed for grinding down more material and leaving a rough finish at the end.

Take these qualities into account when choosing the right end mill for your project. Ask yourself what your goals are and what you want your finished product to look like. The kind of material you’re working with will also dictate which end mill you can use, as some are stronger and more compatible with materials than others. You may also use multiple cutting and finishing tools over the course of a project, as they have unique applications.

0086-813-8127573

0086-813-8127573