Case hardening steel - High Peak Steels - what hardens steel

A Speed Lathe Machine is a high-speed, hand-operated lathe machine, mainly used by woodworkers. It can provide a spindle speed from 1200 to 3600rpm.

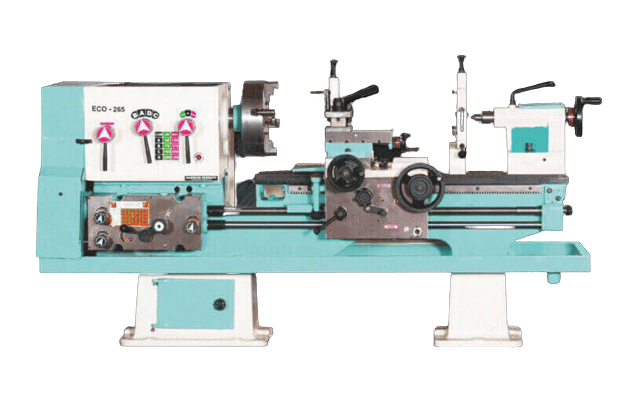

Lathemachine pic with parts name

We continues to enhance our visibility and reputation, including exhibitions all over the world and we also actively taking corporate social responsibility.

You see, this design makes your work a lot easier, all you have to do is simply clamp your workpiece in the chuck, perform the first operation, now rotate the turret, and perform the second operation. You can repeat the process as long as you want.

This is a special breed of lathe machine mostly used to make precision parts and tools such as die, gauges, jigs, and fixtures.

Nowadays the machine is driven by an electric motor but back in the 19th-century people used steam engines to drive the machine. That’s why it is called an engine lathe machine even it does contain an engine nowadays.

It is also called center lathe machine, because back then almost all machine tools were driven by either separate engines or central engines.

Woodlathepictures

If you have a light job that requires lathe machine operations such as turning, facing, grooving, parting, threading, drilling, boring, knurling, and tapping, this machine is for you.

An automatic Lathe machine comes with a group of mechanisms that makes it capable of changing and feeding cutting tools automatically.

Due to their high-speed spindle, speed lathe machines are used for woodturning, furniture making, metal polishing, spinning, and centering.

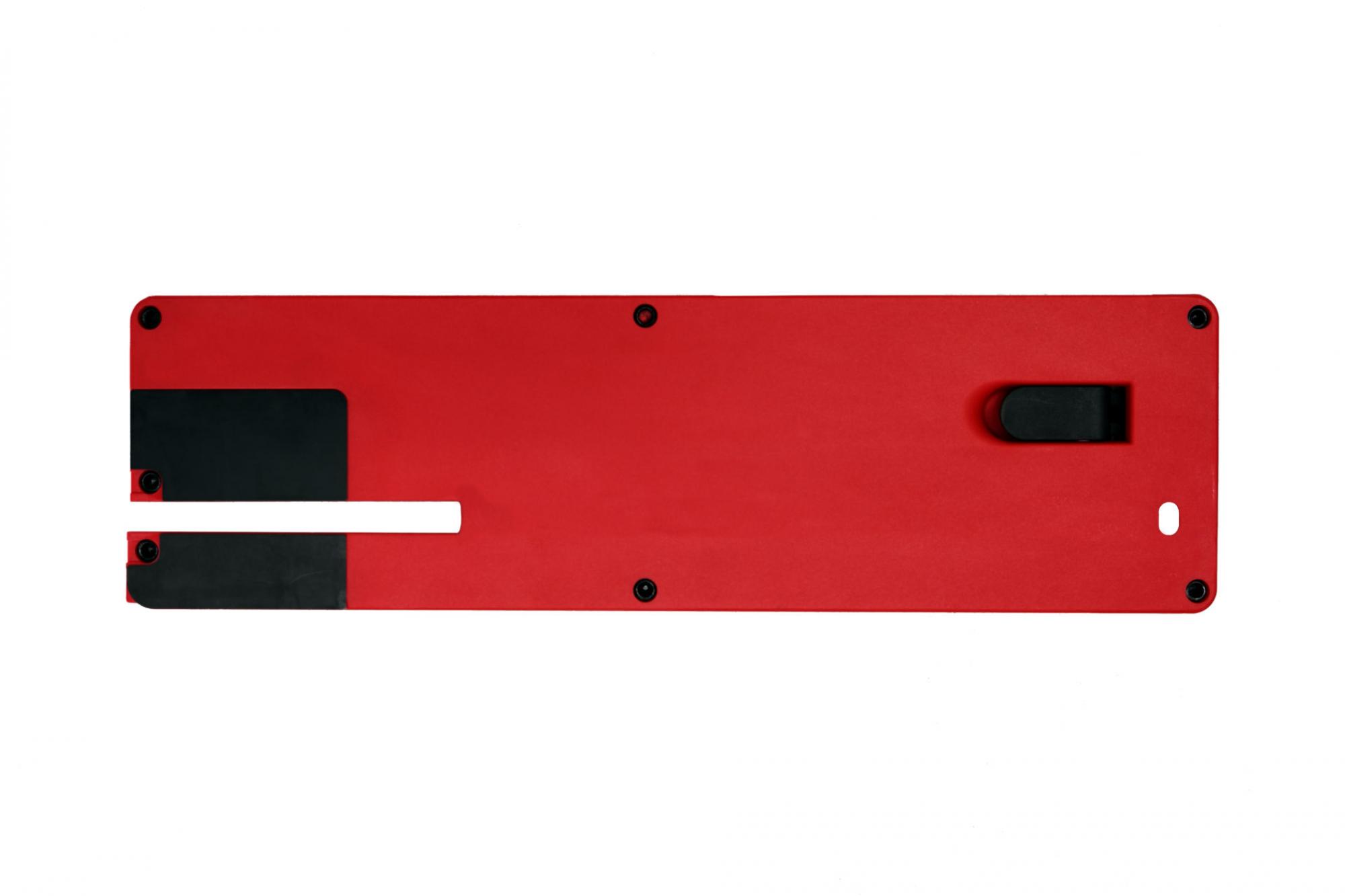

Engineered specifically for SawStop's Compact Table Saw Zero clearance insert for accurate cuts and reduced tear out Positive locking latch allows for tool-free operation 1 Year Warranty

Many people think that you don’t need special skills to operate this machine, however, no one should operate this machine without proper training, it is a very expensive machine, and with a new operator, the chances of an accident increase.

LathPicture

The Standard table saw insert is specifically engineered for the SawStop 10” Compact Table Saw. This zero-clearance insert is for accurate cuts and reduce tear out. One push lockdown allows for tool-free operation and easy install.

SawStop’s commitment to quality, innovation, and safety over the past 20+ years has made us the best in the industry. Learn more about what makes a SawStop North America’s #1 Cabinet Saw

A bench lathe machine is a small-size, hand-operated power lathe, mainly used for small precision work. It looks very similar to speed lathe machines.

Lathemachine parts

You can guess by the name, special purpose lathe machines are custom-tailored lathe machines to suit particular needs. They are mostly used for heavy-duty jobs, where regular lathes can’t be used, or using regular lathes can be costlier or time-consuming.

When you have a job that is complicated precision operations, requires skills, and you have to produce it in mass quantity… this machine is suitable.

It reduces your workpiece load/unload time:yes, just clamp your workpiece once, and perform as many operations you want in a single setup.

This type of lathe machine is used for woodworking and metalworking. You can perform various machining operations on this lathe machine… such as turning, facing, grooving, knurling, threading, drilling, boring, reaming, and many more.

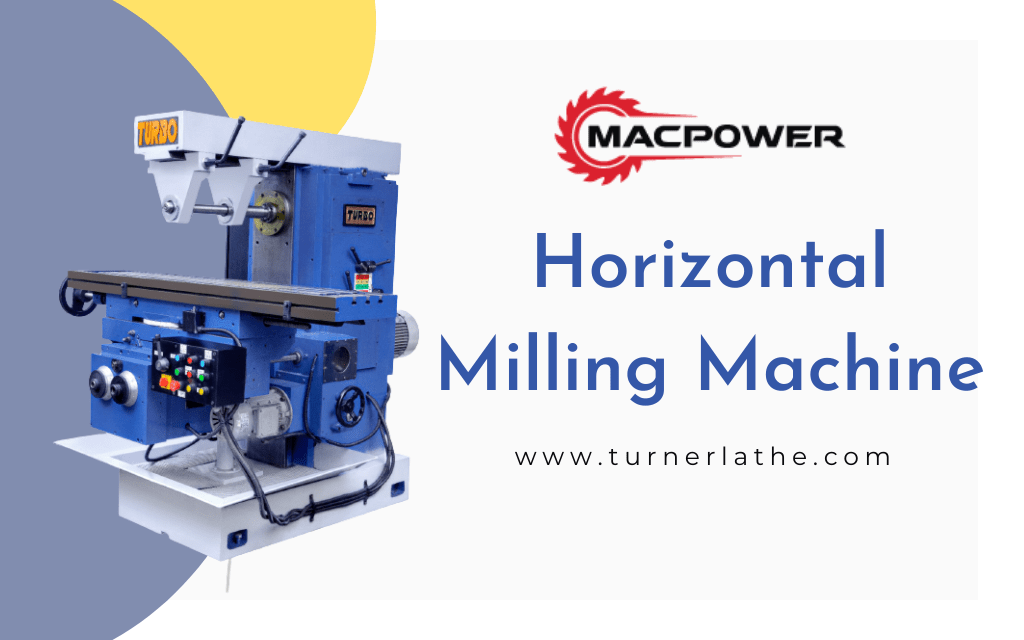

Milling machinepicture

They come with a modern computer numeric control system (CNC). You can use this control system to add a CAD/CAM program and after that, whenever you command the machine, it will start and perform the machining operation according to your program input.

LatheMachine price

Okay, so that was all the information that you might want to know about the types of lathe machines used in workshops and toolrooms.

I hope you liked it. Feel free to share this post… and… if you have any questions related to lathe machine types––you can ask us simply by filling out the contact us form.

In this turret, you can set up multiple cutting tools (usually up to 6 tools), such as drilling, countersinking, reaming, tapping, etc.

It looks similar to an engine lathe machine. But it is made from more accurate and precise parts than an engine lathe machine. Thus, the price of a toolroom machine is higher than an engine lathe machine.

A turret lathe machine is an advanced lathe machine used for mass production. It is kind of an upgraded version of an engine lathe, where the tailstock is replaced by a revolving hexagonal turret.

0086-813-8127573

0086-813-8127573