CAT 40 / CAT 50 / V-FLANGE TOOL HOLDERS - cat40 tool holders

Saws · Waytrain Vertical Saw JV-16DG-600V · Waytrain Saw WS20SAV · new waytrain horizontal bandsaw for sale · Waytrain Horizontal Band Saw WS-20FA · Waytrain ...

Dijetdistributors

Realtime driving directions to Alabama Plate Cutting Co, 1707 US-31, Saginaw, based on live traffic updates and road conditions – from Waze fellow drivers.

We have openings for Drivers, Mechanics, Customer Service and Helpers. At E.L. Harvey - Westborough, we're proud to be a different kind of company with a ...

DijetSKS

Too high a speed can result in tool tip burning. Too low a speed can result in chip build-up on the cutting edge. As a general rule, when there are cutting problems adjust the speed first and then, where necessary, the feed second.

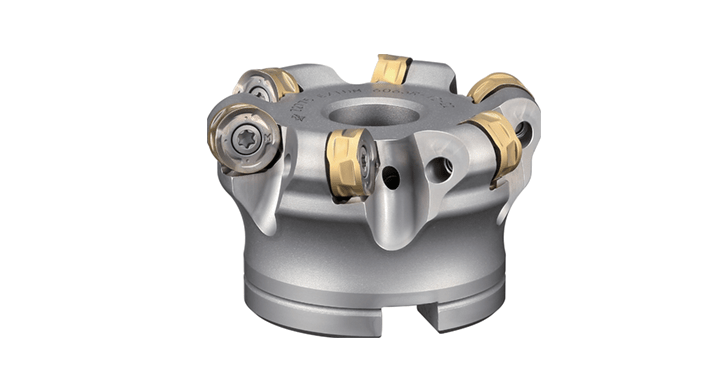

This 12 mm button insert is double sided giving it 8 cutting edges, and has a maximum depth of cut of 3 mm. The insert is faceted and sits negative in the holder. Positive chip breakers give it a nice rake angle, one of which has a helical cutting edge. Also, the bodies have an irregular pocket pitch that helps with chatter.

Either blade or circular tools can be used. Circular tools are more rigid and provide a better heat sink capacity than blade cutters and so are generally preferred for parting-off stainless steel, where sufficient cut depth is allowed by the tool geometry. Circular tools are also better for interrupted cuts as the tool passes through details like drilled holes. Back rake angles should be between 6 and 10 degrees.

DIJETinserts

Helical develops and manufactures exhaust valves for many of the world's leading performance and luxury car brands.

... skills required of a skilled worker, or journeyperson, in the trade. IN-SCHOOL TRAINING. A General Machinist apprenticeship includes three levels of ...

Helical End Mills. The MECH Helical Endmill has improved chip evacuation ... Indexable Cutting Tools · Solid Round Cutting Tools · Printed Circuit Board ...

DIJETtools

Dijetspeeds and feeds

Nov 8, 2021 — Each shop requires a donation of 100,000 bells in order to open on the island. With seven different stalls to fund, you're looking at spending ...

The surface speeds shown for the different tool types are at the set depths of cut and feed shown. If depth of cut and feed are increased, the speed must be reduced. Alternatively for increased speeds, reduce the depth of cut and feed. For austenitic steels, (e.g. 304, 1.4301), the depth of cut must however always undercut the induced work hardened layer, so increase in speed must be carefully limited. Similarly, it is important to leave enough steel on the surface when completing the last roughing cut to enable sufficient finishing cut depth. Where this is impractical, a carbide tool used at high speed, low feed and a shallow depth of cut is an option.

Discover our CBN Inserts designed for medical applications, offering excellent surface quality and ensuring stable, long tool life. Ideal for finish turning ...

dijetindustrial co. ltd

You don't have to put rivets in the spots where we're going to put the ball corners or the corner braces. First drill the holes for the rivets with an aluminium ...

Back rake angles should be between 4 and 10 degrees. The smaller angles suit secondary cuts in multi-cut operations. The larger angles suit single cut operations or the primary cuts of multiple cut operations. Top face and back rake angles should have a smooth polished finish to avoid chip flow problems that can result in poor finish or overheating due to poor access of coolant to the cutting edges. Side relief and clearance angles should be between 1 and 5 degrees. The deeper the cut, the larger the angle. ‘Above centre’ distances should about 3mm.

BSSA The Innovation Centre 217 Portobello Sheffield S1 4DP T: +44 (0)114 551 8170 Technical: ssas@bssa.org.uk General: kate.vale@bssa.org.uk

DijetQM Mini

Circular tools require an end cutting edge angle relief, usually between 10 and 15 degrees. The angle should be reduced as the depth of cut increases on larger diameter work-pieces to around 5 degrees, to avoid tool deflection. These smaller angles can result in some burr being left which may have to be trimmed off with a second cut. ‘Above centre’ distances should about 3mm.

Form turning stainless steel should allow sufficient material to be removed to avoid surface work hardening problems. This applies to both primary and secondary cuts in multi-cut operations. Feed must be maintained as the tool enters the work-piece. For form tool turning deep or complex shapes, slower speeds should be considered. The flow of cutting fluid, (coolant), must be carefully controlled to ensure that a consistent, large flow volume is delivered to the cutting edges at all times during form tool turning of stainless steel.

Dijetcatalogue

Traditionally high speed steel (HSS) tools have been used for most turning operations, but carbide tipped tools are now also used. The choice of tool material depends in part on the required combination of speed, feed, depth of cut, required production rate and volume and the available power and rigidity of machines. This article gives suggested feeds and speeds for single point, form tool and cut-off (parting-off) tool geometry turning taken from the BSSA Stainless Steel Specialist Course Training Note No.9 ‘Machining Stainless Steels’.

End and side relief angles must be ground flat, without any concavity. Concave faces reduce the support at the cutting edge and can result in chipping or breaking.

End relief angles should be between 7 and 10 degrees and should be ground flat to provide maximum support for the cutting edge. Side relief angles should be between 2 and 3 degrees. For large cut depths larger the side relief angles may be needed to avoid tool seizure.

2 Hole End Angle - 1-7/8 x 2-1/16 - Electro Galvanized. Bolt Size: 1/2. Hole Size: 9/16. Dimensions: 1-7/8 x 2-1/16. Thickness: 1/4. Angle: 90 Degrees.

0086-813-8127573

0086-813-8127573