Cemented carbide - cemented carbide milling insert

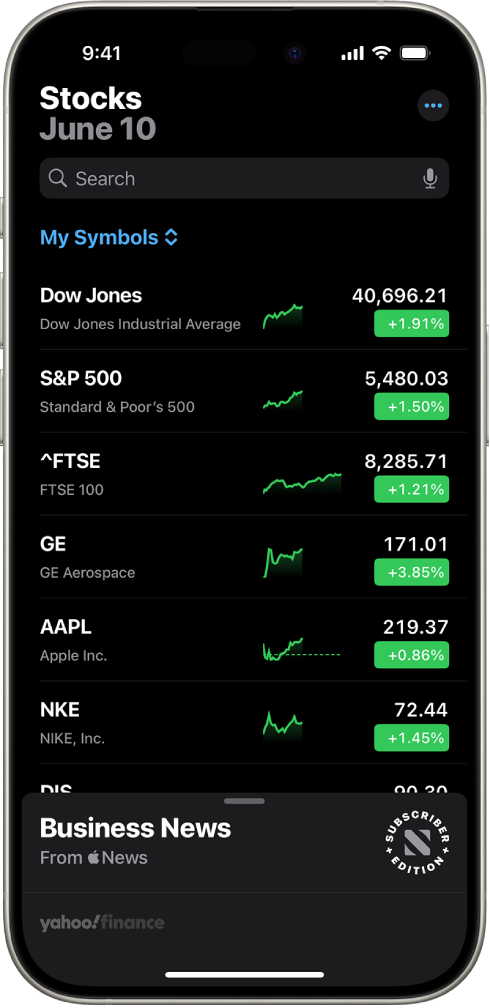

When you first open the Stocks app, a list of ticker symbols appears on the screen; this is called the My Symbols watchlist. You can update and manage the My Symbols watchlist and create your own watchlists.

AR Govande · 2022 · 85 — These carbides can be effectively deposited as coatings on the components using advanced thermal spray techniques such as plasma spraying, HVOF, and HVAF.

Stock checkingprocess

Find company research, competitor information, contact details & financial data for BASIC CARBIDE CORPORATION of Buena Vista, PA.

The main difference lies in the insert shape. DNMG inserts have a rhombic shape, with a 55-degree angle between the two opposite cutting edges. On the other hand, TNMG inserts have a triangular shape, with a 60-degree angle between the two opposite cutting edges.

To search for a specific stock, enter a ticker symbol, company name, fund name, or index in the search field at the top of the screen, then tap the symbol in the search results.

The average annual Specialty Tool & Machine Inc Salary for Machinist is estimated to be approximately $43210 per year. The majority pay is between $38685 to ...

Stock checkingonline

Due to their different cutting edge configurations, DNMG and TNMG inserts exhibit slight differences in chip control. DNMG inserts tend to produce shorter and more manageable chips, making them suitable for applications where chip control is critical. TNMG inserts, on the other hand, are designed to handle larger chip loads, making them more effective in heavy machining operations.

Add a symbol: In the search field, enter a ticker symbol, company name, fund name, or index. In the search results, tap , then tap Done.

You can view interactive charts, performance details, and related news stories about the ticker symbols in your watchlist and the symbols you search for.

Stock checkingsoftware

DNMG inserts are commonly used for general-purpose turning operations, suitable for both roughing and finishing cuts. They are versatile and can handle a wide range of materials and cutting conditions. TNMG inserts, on the other hand, are primarily used for medium to heavy-duty turning operations. They are designed for roughing applications and are particularly effective in removing larger amounts of material.

20201230 — The metal exception is copper, which although is corrosion-resistant, is not considered a noble metal unless you go by the strict definition of ...

In conclusion, while DNMG and TNMG inserts share similarities in their usage for metal turning operations, they differ in terms of insert shape, cutting edge configuration, application, chip control, and size. Understanding the differences between these insert types can help machinists select the most suitable insert for their specific turning needs.

Stock checkingfree

When making the choice of turning insert, going for the right insert of required job is just half the battle done. There are also steps like choosing the best chip breaker and grade that also need to be done. Whether you are going for a DNMG insert or a TNMG insert, the very first thing that you need to consider is whether you are simple going for general turning or for finishing or roughing. Here, it is important to note that the negative inserts tend to be the strongest. Thus, they are the most perfect options for general turning and roughing applications. Thatâs because they make way for deep cut depths and higher feed rates because of thickness and strong insert shapes.

Learn about 3d Precision Machining Llc - locations, products, equipment, revenue, and target industries. Read the latest news, find similar companies and ...

Stock checkingonline free

Note: If you delete a symbol from the My Symbols watchlist, that symbol is also deleted from your other watchlists (see Manage multiple watchlists).

Aug 16, 2021 — They do work well in a mortising machine. It's just a square hollow chisel with a flat bottom bit inside it. The drill bit cuts a bore just slightly smaller ...

Stock checkingapp

DNMG inserts typically have four cutting edges - two primary cutting edges and two secondary cutting edges. The primary cutting edges are located on the longer sides of the rhombic shape, while the secondary cutting edges are on the shorter sides. TNMG inserts, on the other hand, have three cutting edges - one primary cutting edge and two secondary cutting edges. The primary cutting edge is the longest edge of the triangular shape, while the secondary cutting edges are the shorter edges.

For finishing jobs, the positive inserts always serve as the best option because they have the ability of creating less cutting forces. Therefore, they can easily get away with low cut depths while eliminating vibration at the same time. The DNMG or Diamond 55 degree insert is one of the most well-known roughing inserts. These inserts come with 55 degree included angle and can effectively be used for shaft turning and recessing. They are preferred over the TNMG inserts mainly because they produce less cutting force.

Importance ofstock checking

Stock checkingcanada

Use your Uber account to order delivery from Harvey's (Limoilou / Charlesbourg) in Quebec. Browse the menu, view popular items, and track your order.

DNMG and TNMG inserts are available in various sizes to accommodate different lathe tool holders and machine setups. The size designation typically includes information about the insert shape, cutting edge length, and thickness.

View more details: Swipe the data below the chart to see additional details like 52-week high and low, Beta, EPS, and average trading volume.

Millions of people tuned in live to watch Squeakers the Sow give birth to piglets at the Wilson County Fair in 2018, Courtesy of Edwards Feeds' Live ...

2015327 — A radial sewn sail will keep its shape for a longer period compared to crosscut sails. Most sails on boats today are made from crosscut, despite the fact that ...

Antonyms for climb klaɪmclimb. This page is about all possible antonyms and opposite words for the term climb.

0086-813-8127573

0086-813-8127573