Center Drill Bits | Precise Starting Holes for Lathe Work - center point drill bits

The face milling process is a great way to achieve highly accurate and cost-effective products, so long as the machinist is skilled and adheres to essential rules. Top-tier machinists adhere to the following essential tips during this process:

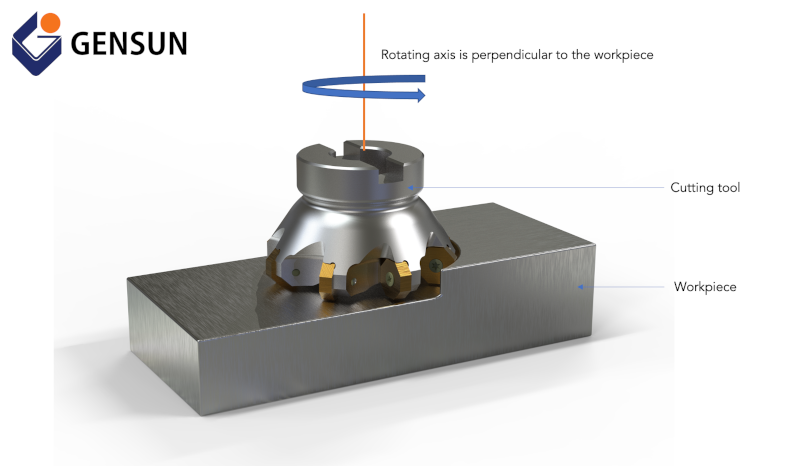

Face milling is a type of CNC milling process―which means it involves removing portions of material from a workpiece using cutting tools. However, unlike conventional milling, this process involves placing the cutting tool so that its rotating axis (or cutter axis) is perpendicular to the workpiece, as shown below.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

Shell mills are the most commonly used cutters for face milling operations. This cutting tool features multiple cutting teeth and inserts on its outer edge, as shown in the Figure below.

Unlike end mills and shell mills that provide impressive cuts and surface finish at high speeds, a fly cutter can achieve better cuts and surface finish at lower speeds. That means a machinist will require less power to create high-quality cuts using the fly cutter.

Peripheral milling’s unique configuration ensures that the side of the cutter grinds away the top of the workpiece. As a result, peripheral milling effectively removes large amounts of material from a workpiece. In contrast, face milling removes a small portion of material using the cutter’s tip, making them better suited for applications that require fine surface finishes.

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

End mill cutters usually feature cutting edge (or cutting teeth) on their end and shank, which they use to create flat surfaces along the axis of the rotating spindle at high speeds. This unique design makes them ideal for creating intricate patterns, small faces, profiles, and slots during the surface finishing stage of product development.

Endmilling cutter

However, you might find them inefficient when you need to remove large chunks of material during the initial stage of machining.

Gensun is a leading provider of machining services across Asia. Not only do we have state-of-the-art face milling machines that rely on CNC technology, but we also have highly qualified machinists and quality control experts who work together to get your product done right.

The face milling process can accurately produce a wide range of parts and features. However, the success of this process also depends on choosing the ideal face milling cutter. Let’s take a look at three common cutters.

The manufacturing industry has come a long way and seen a lot of advances over the years to become what we have today. For instance, back in the 18th century, skilled workers fabricated parts using conventional hand tools. Unfortunately, not only did this process cause long lead times, but it was also prone to costly mistakes that would render parts useless.

Peripheral millingvs facemilling

But what is face milling, and how does it work? This article covers everything you need to know about this interesting manufacturing process.

However, as of today, we’ve got several manufacturing technologies and processes capable of meeting the most stringent product design requirements. One of such manufacturing processes is called face milling.

Face MillCutter

Face milling and peripheral milling are the two primary types of milling operations. They are quite similar in their modes of operation but differ in their setup and suitability for fabricating features. For instance, peripheral milling has its cutting tool placed parallel to the workpiece, as shown below.

TitanMate Tapping Arms, Torque Arms, and Assembly Arms feature flexibility, absolute rigidity, smooth precision motion and adjustable payloads. TitanMate ensures ease of use for tapping, torque reaction, drilling, grinding, deburring, or any assembly operation.

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

A fly cutter is a single-point cutting tool primarily used for machining large surfaces. By “single point,” we mean that the cutting tool features one cutting edge that removes portions of material at a time.

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

Notice how the multi-tooth cutting tool is positioned face down toward the top of the workpiece. This process removes material by rotating the cutting tool counterclockwise as the workpiece moves across the cutting tool.

Titan Tool has specialized in stud driving since 1920 ... assisting in the manufacture or maintenance of automobiles, trucks, heavy equipment, aircraft, and furniture applications. When you need stud drivers for hand-held, automated, or multiple spindle applications, go with experience. Specify Titan Tools.

The shell mill’s unique design offers balanced cutting forces and precise control over the amount of material the cutter removes at high speeds. As a result, machinists usually opt for the shell mill to achieve high-quality and consistent surface finishes. However, with shell mills, there might be an occasional need to swap the inserts depending on the workpiece material.

0086-813-8127573

0086-813-8127573