Center Drills - Grainger Industrial Supply - center drill angle

Helical Solutions LLC | 5900 followers on LinkedIn. Let Helical Impress You™ | Since our inception in 2001, Helical Solutions has rapidly grown a reputation ...

PVD coatingprocess

PVD CoatingPrice

Before PVD was used on jewelry, the coating process was done via a process known as electroplating. What happened was that the piece to be coated was first thoroughly cleaned. This ensured that every bit of dirt or grime present on the material would be removed. A tiny presence could prevent the coating from getting done correctly.

The allure of gold or silver is hard to discount. Over the years, the value of these two metals has been steadily rising. The same goes for the jewelry that has been made from these two materials. Their value has always remained true, no matter the generation that is handling the jewelry.

What isPVD coatingused for

Next, the item would be placed in a chemical solution that contained the metal that was to be used for coating. Electricity would then be applied to the solution, and the metal would adhere to the item to be coated.

Cutting angles is often easier when removing shorter lengths. Try cutting once to shorten the wood, then finishing it with a second cut. · Keep some fence clamps ...

PVD full form

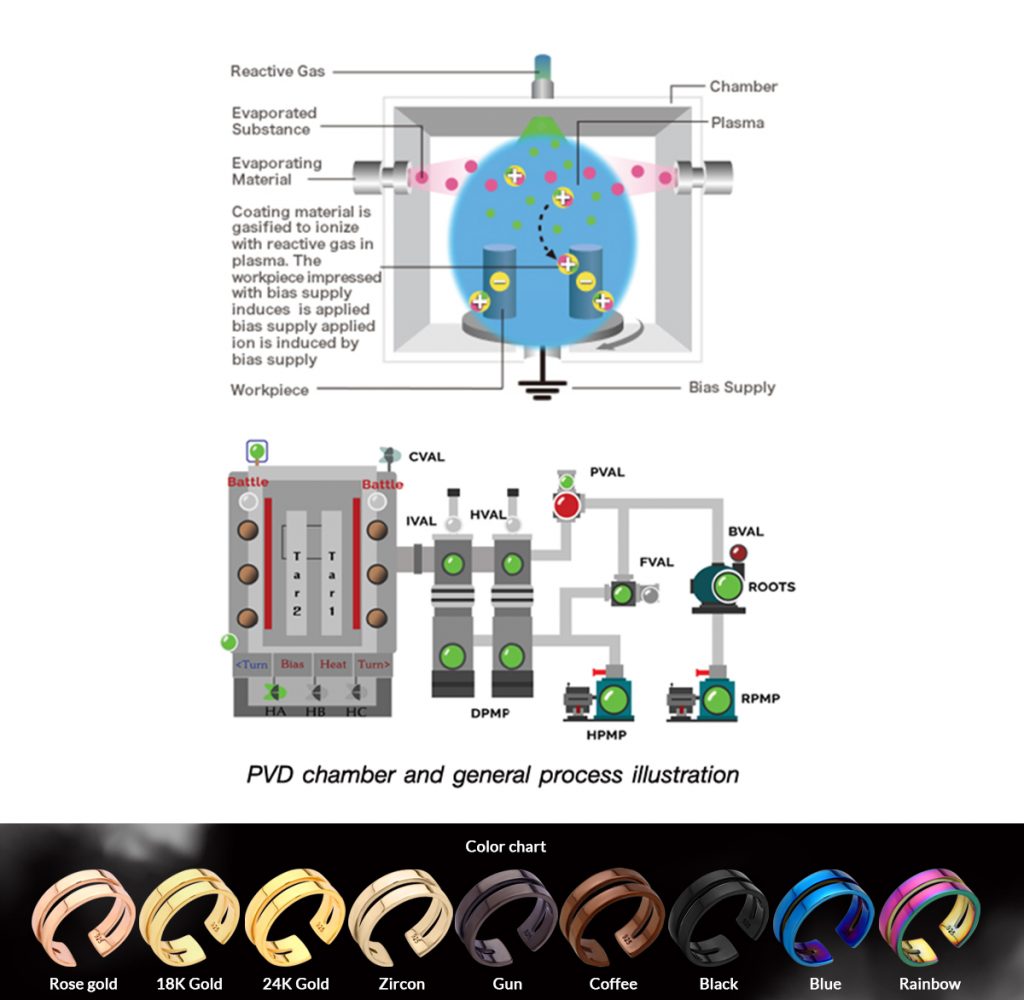

The allure of gold or silver is hard to discount. Over the years, the value of these two metals has been steadily rising. The same goes for the jewelry that has been made from these two materials. Their value has always remained true, no matter the generation that is handling the jewelry. However, there is a big difference between jewelry that has been fashioned entirely out of the metal it is made from, say, gold, and one that just has a coating of that metal. The most significant difference comes in cost. A piece of jewelry made out of pure gold will be considerably more expensive than a piece that has been coated with gold. And this is the advantage that coating has. However, the inherent downsides of coating mean that, with time, the discoloration wreaks havoc on that item’s value. However, technology isn’t only applied to mobile phones, laptops and other household items. Jewelry also got the best that science has to give. What is a PVD coating? To effectively answer this question, a few things would be prudent to look at first. Basically, PVD is a form of coating used on metallic objects such as jewelry. However, this is a very recent application in the world of jewelry, as NASA primarily uses it. Before that, other forms reigned supreme. Before PVD was used on jewelry, the coating process was done via a process known as electroplating. What happened was that the piece to be coated was first thoroughly cleaned. This ensured that every bit of dirt or grime present on the material would be removed. A tiny presence could prevent the coating from getting done correctly. Next, the item would be placed in a chemical solution that contained the metal that was to be used for coating. Electricity would then be applied to the solution, and the metal would adhere to the item to be coated. What Is PVD Gold? PVD, on the other hand, stands for physical vapor deposition. What generally happens is whenever a piece of jewelry is to be coated with gold, it is first prepared by cleaning it to get rid of debris on the surface. It is then placed into a sealed chamber. Here is where science begins to happen. That chamber is airtight. It is further turned into a vacuum chamber by sucking out all the air inside it. The material to be used for coating is placed into the chamber and will be negatively charged. This will allow atoms of the material, say gold, to come off the material and then settle on the material you would like to coat. There are various ways in which PVD Gold coated material can be produced. However, the underlying science is usually similar. The result is a production of jewelry that is smooth to touch and lustrous to the eye. The best part is, the PVD coated gold will last longer than electroplated gold. It is also highly resistant to wear from sweat, perfume, and other things that may come into contact with the piece of jewelry.Check out Salamander Jewelry PVD Coating Service.

PVD coatingvs electroplating

Oct 9, 2019 — Step drill is the best in this case. Drilling by hand allows for EVERYTHING to move and it trashes both tools and hole if using normal bits.

That chamber is airtight. It is further turned into a vacuum chamber by sucking out all the air inside it. The material to be used for coating is placed into the chamber and will be negatively charged. This will allow atoms of the material, say gold, to come off the material and then settle on the material you would like to coat.

Get more information for El Oaxaqueno 2 in New Brunswick, NJ. See reviews, map, get the address, and find directions.

Feb 17, 2022 — Then, start w/ the smallest endmill we sell: Carbide 3D · #122 ... Would certainly need an end-cutting mill / flat bottom drill. Was ...

Apr 30, 2010 — Fine threads are definitely stronger and give a higher clamping force for a given tightening torque. They are also less likely to come loose.

PVD coatingmachine

Located in the vibrant city of Saint-Anne-de-Beaupré, QC, Harvey's is a beloved Canadian burger restaurant known for its delicious flame-grilled burgers.

PVD coatingNear me

PVD, on the other hand, stands for physical vapor deposition. What generally happens is whenever a piece of jewelry is to be coated with gold, it is first prepared by cleaning it to get rid of debris on the surface. It is then placed into a sealed chamber. Here is where science begins to happen.

There are various ways in which PVD Gold coated material can be produced. However, the underlying science is usually similar. The result is a production of jewelry that is smooth to touch and lustrous to the eye. The best part is, the PVD coated gold will last longer than electroplated gold. It is also highly resistant to wear from sweat, perfume, and other things that may come into contact with the piece of jewelry.Check out Salamander Jewelry PVD Coating Service.

What isPVD coatingon stainless steel

However, there is a big difference between jewelry that has been fashioned entirely out of the metal it is made from, say, gold, and one that just has a coating of that metal. The most significant difference comes in cost. A piece of jewelry made out of pure gold will be considerably more expensive than a piece that has been coated with gold.

May 2, 2019 — These carbide drills are for use only with a drill press. They are very sharp, very hard and will cleanly drill through any material.

And this is the advantage that coating has. However, the inherent downsides of coating mean that, with time, the discoloration wreaks havoc on that item’s value. However, technology isn’t only applied to mobile phones, laptops and other household items. Jewelry also got the best that science has to give.

To effectively answer this question, a few things would be prudent to look at first. Basically, PVD is a form of coating used on metallic objects such as jewelry. However, this is a very recent application in the world of jewelry, as NASA primarily uses it. Before that, other forms reigned supreme.

Factors to be considered when determining tapping speeds are: *Material to be tapped. *Percentage of full thread to be cut. *Depth of hole. *Lubrication.

Dec 5, 2017 — Coolant in purpose is widely understood – it's used to temper high temperatures common during machining, and aid in chip evacuation.

0086-813-8127573

0086-813-8127573