Chamfer Mills - carbide chamfer tool

“Machine tool life suffers when concentrations drop below the coolant manufacturers minimum concentration suggestions and can cause rust on the machine tool,” says Treese. “There’s just not enough chemical to protect the machine tool.”

ISCAR's multi-function drills (DRM family and DR-MF family) are designed to perform a variety of operations with a single tool, significantly reducing machine idle time due to tool changes.

Yes, Very good initiatives on the subject of maintenance of coolant systems, but still lot of issues like blockage of coolant pump, total coolant line, hoses, Tool disc blockage, reducing coolant pressure, tool life, part finish, like somany things also can be taken as a subject.

“Tramp oil will slowly dissolve into the coolant, causing to it to get thicker and stickier with time,” Treese explains. “Bacteria can feed easily on this emulsified tramp oil and then can attack the coolants’ oils as well. It is also harder to maintain the proper concentration when the sump is full of chips.”

In principle drilling always takes place from the outside to the inside. For example, the bore entrance and the countersinking is in the outer skin that ...

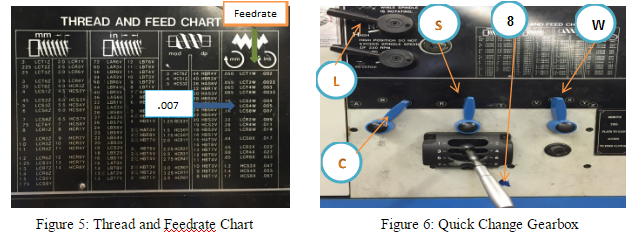

We can control the feed on an engine lathe by using the change gears in the quick-change gearbox. Our textbook recommends whenever possible, only two cuts should be taken to bring a diameter to size: a roughing cut and a finishing cut.

Already dealt with the health issues but need some more direct advice on coolant maintenance and disposal? Read “4 Tips to Optimize Machine Fluid Maintenance and Coolant Disposal.”

In order to eliminate this time loss, we can, and should, use recommended metal-removal rates that have been researched and tested by steel and cutting-tool manufactures. We can find these cutting speeds and metal removal rates in our appendix or in the Machinery’s Handbook.

“The dirt in your coolant will be abrasive, it will scratch paint, and it will scratch the glazing on a machine’s windows inside a newer machine with a cabinet around the workzone,” says Brumgard. “The other thing it can hurt and wear out are pumps, especially high-pressure pumps, even when they have extra filtration to protect the pump from wear.”

Machinist coolantreview

Hello Saun, when you recharge the machine sump make sure you use Whamex by masterfluid solutions . it will clean the machine thuroughly. first run a skimmer Second thing is to run an aerator in the sump as far away from the skimmer as you can. the bubbles push trampoil to the skimmer third coolant should be mixed with dionized water for the best results and if uyou still have an issue , use a biocide anti bactia solution. I would suspect you would not need to if you follow all the steps

Though less noticeable, the delicate tissue lining our lungs is even more susceptible to irritation than our skin. This can be especially problematic at higher spindle speeds, where fine mists are generated and easily inhaled. Unfortunately, the negative health effects connected to mist might not be noticed until years later. No one wants to wear a face mask at work, but if your lathe or machining center isn’t equipped with a properly sized, high-performing air purifier and mist collector, doing so would be an excellent idea, even if you do perform routine cutting fluid maintenance. Clean coolant might smell darned nice, but that doesn’t mean you should inhale it.

A lathe work cutting speed may be defined as the rate at which a point on the work circumference travels past the cutting tool. Cutting speed is always expressed in meters per minute (m/min) or in feet per minute (ft/min.) industry demands that machining operations be performed as quickly as possible; therefore current cutting speeds must be used for the type of material being cut. If a cutting speed is too high, the cutting tool edge breaks down rapidly, resulting in time lost recondition the tool. With too slow a cutting speed, time will be lost for the machining operation, resulting in low production rates. Based on research and testing by steel and cutting tool manufacturers, see lathe cutting speed table below. The cutting speeds for high speed steel listed below are recommended for efficient metal removal rates. These speeds may be varied slightly to shift factors such as the condition of the machine, the type of work material and sand or hard spots in the metal. The RPM at which the lathe should be set for cutting metals is as follows:

Machinist coolantfor metal

They never change coolant at b and r machine 305 moody St. Ludlow MA. This shop is infected all of us that work there sad

Here are a few pointers you should keep in mind if you’re to optimize productivity while protecting the shop’s most important assets: its workers.

Is CNCcoolantdangerous

As a rule, water-soluble or “miscible” cutting fluids are fairly alkaline, with a pH of around 8.6 or higher. This helps to prevent corrosion of metal surfaces, keeps microorganisms in check and is a bit easier on human skin. It does, however, tend to eat paint and even rubber seals, especially on older machines not designed with modern cutting fluids in mind. To minimize this, it’s a good idea to wipe equipment down before going home at the end of each shift. Regularly inspect seals and wipers for wear and replace as needed. Install a skimmer on each machine to eliminate tramp oil, bacteria’s favorite food.

Most machinists would agree that a properly mixed, high-quality cutting fluid does smell quite pleasant. But if it is not maintained or cleaned, after awhile, cutting fluid can stink. Give it a couple of weeks of neglect and the Monday morning stench is enough to make even the most olfactory-challenged machinist yearn for the weekend. If the assault on your nose isn’t bad enough, however, rancid coolant is hard on other things too, starting with your health—and can negatively affect tool and machine life, finishes and a host of other key metalworking processes and parts.

4. What would the RPM be if we were turning a 1.00” diameter workpiece made out of mild steel, using Carbide cutting tool?

water-basedcoolantfor machining

It’s better to focus on maintaining a clean coolant operation. Here are some ways: Aside from skimming and filtration, cutting fluid concentration should be checked with a refractometer at least weekly, refreshing tired coolant as necessary with properly mixed makeup fluid. One way to accomplish this is with an automatic proportioning unit that sits on the drum, allowing the operator to dial in whatever percentage of fluid is needed to bring the sump back to the correct concentration. If you don’t have such a unit, remember the acronym OIL, short for “oil in last,” when mixing any cutting fluid. Your cutting tools will thank you.

6. As the softness of the material decreases, the cutting speed increases. Additionally, as the cutting tool material becomes stronger, the cutting speed increases.

Annular Cutter · Cutting Tools · Machine Tool Access · Measuring Instrument · Magnetic Drills · Carbide Inserts · Construction Tools · MG-Tiger.

Dirty metalworking fluid can cause a host of problems for your CNC machining operation and can be harmful to machinists—if not cared for properly. Here are the top reasons for keeping your coolant and filters clean and maintained—with advice on how to manage it.

Bestcoolantfor CNC machines

But be careful, warns Treese: “If a manufacturer of coolant recommends a 10 percent concentration in the sump, running at 20 percent actually doubles the amount of chemical in the sump—it does not add 10 percent more chemical as some think.”

Your solution seems interesting since no one really wants to use biocides in their coolant to make it even more toxic than it already is. Would it be possible to have a sample to see that it's working? How much of this stuff do you need to add to your tank in percentage ?

There are several reasons to keep machines clean, and these reasons make it more evident why to keep the machining coolant clean. Dirty coolant reduces the effectiveness, which reduces the quality of the machined parts.

The lathes are designed to operate at various spindle speeds for machining of different materials. There speeds are measured in RPM (revolutions per minute) and are changed by the cone pulleys or gear levels. One a belt-driven lathe, various speeds are obtained by changing the flat belt and the back gear drive. One the geared-head lathe speeds are changed by moving the speed levers into proper positions according to the RPM chart fastened to the lathe machine (mostly on headstock). While shifting the lever positions, place one hand on the faceplate or chuck, and form the face plate slowly by hand. This will enable the levers for engage the gear teeth without clashing. Never change speeds when the lathe is running on lathers equipped with variable speed drivers, the speed is changed by turning a dial of handle while he machine is running.

So that means there’s a cost of changing filters and making sure the filter is changed and not bypassed or ignored, Brumgard explains. Some might think to remove the filter, but then you start to really wearing out costly components. And with through-the-tool coolant delivery holders, you have to pay attention to the rotary coupling’s wear, to avoid leakage, Brumgard points out.

There is a better way. Whether you call it a sump sucker, sump doc, or sump shark, anyone with more than a handful of CNC machine tools should seriously consider investing in one. Instead of slippery floors, chips and rags everywhere, and an hour or two of backbreaking work, sump cleaners are fast and clean. Wheel one of these self-contained units up to the machine, remove the sump’s access panel, and get sucking—15 minutes later and you’re back in business. Some units clean and filter the old coolant as they work, while others are equipped with a “clean side” reservoir containing fresh coolant—either way, sump docs are a smart investment if you’re aiming for the lowest coolant costs and best machining performance possible.

That’s why coolant should be treated with respect. Wash hands regularly with a mild, nonabrasive soap. Use a moisturizer to create a protective skin barrier that slows the absorption of chemical additives. Wear thin nitrile gloves if practical (though never wear heavy gloves around machinery). Keep clothing clean and dry. And avoid using solvents to clean parts, as these eliminate the natural oils on our skin, leaving it unprotected.

Types ofcoolantused in machining

Whenever possible, only two cut should be taken to bring a diameter cut. Since the purpose of a rough cut is to remove excess material quickly and surface finish is not too important. A coarse feed should be used. The finishing cut is used to bring the diameter to size and produce a good surface finish and therefore a fine feed should be used.

7.W = Select Feed Ranges and change to W on this lever (See Figure 3) Before turning on the lathe, be sure all levers are fully engaged by turning the headstock spindle by hand, and see that the feed rod turns.

“At low concentrations bacteria can grow unimpeded in the sump and cause pH of the coolant to drop and cause rust,” says John Treese, director of global training at Master Fluid Solutions. “Low concentration [of fluid] can grow bacteria that can aggravate skin issues including simple cuts and scratches. High concentration adds too much chemical that can do the same.”

Hi Jeremy, Refer to the SDS sheet for proper handling and storage and purchase an approved container that will be able to capture and store the coolant. MSC has multiple choices for this purpose (even beyond this link)- https://www.mscdirect.com/browse/tn/Material-Handling-Storage/Totes-Stor.... The containers should also be labeled and we suggest you place sorbent pads below them to avoid spillage or leaking, making sure the proper containment is used based on the volume of the potential spill (https://www.mscdirect.com/browse/Safety/Spill-Control-Containment/Sorben... ). You can create your own labels here- https://uniquify.nationalmarker.com/msc#1. Also, due to the slip and fall potential, the collection areas should be blocked off. One way to do this would be to use barricades.

It has been my experience to take at least three cuts. One to remove excess material quickly: the rough cut, one cut to establish finish and to allow for tool pressure, and one to finish the cut.

CNC machineCoolantPrice

The water is also important—invest in a deionizer or reverse osmosis system where possible, but do not use softened water. Like Goldilocks, machining operations benefit from cutting fluids that are not too soft, not too hard, but just right.

Optimizing coolant or metalworking fluid parameters can significantly impact roll grinding quality, consistency and performance.

Aside from creating noxious odors and degrading coolant, these microorganisms—when combined with tiny skin abrasions—can hasten the chance of infection. “Microabrasions,” as they are known in the industry, happen when extremely fine chips and swarf reside in dirty coolant, not so much the larger chips we see flying off the workpiece during the cutting process, explains Jim Brumgard, an application engineer in Castrol’s industrial division.

My name is John Mathew Am willing to make some purchase of some items with your company and ship to Belize. Before we proceed can you please answer the following question below ;

Here again, maintenance is key. The mantra is: Skim constantly, clean regularly and check religiously. Watch fluid concentrations, using no more concentrate than is necessary but without skimping—as a rule, 10 percent is a good starting point for general-purpose work, although difficult materials such as titanium and superalloys may call for a slightly higher percentage, while aluminum generally cuts best with a leaner mix.

“Of course, big chips can cause cuts, but that type of cut usually requires first aid,” says Brumgard. “The skin abrasions occur when there is coolant splashed onto the skin and then the operator wipes away the dirty coolant … These often microscopic tiny fines will cause the scratches as the towel or rag is wiping them across the skin.”

You must mention the use of Centrifugal Pump Carts , they put the coolant thru a pump that separates the way oil from the coolant, then it filters the coolant, and now you have really clean coolant. Skimmers are ok, but they never get all the oil, plus they always suck up good coolant. Also, the use of a Homogenizer can make the coolant last a long time. I was on an interview at a shop in Virginia, over 160 cnc machines, they constantly run coolant thru centrifugal pump carts and homogenizers, and they claim to have never disposed of old coolant, because they are always renewing the coolant. Some shops run those little goldfish tank aerators/filters in the sump on the weekends to continually circulate the coolant. Zebra Products sells a similar device that is better suited for coolant/oil. If you keep your coolant clean, it is one less reason for a worker to quit the job, I've seen more filthy shops than I care to tell, places that never cleaned out sumps, workers spitting chewing tobacco into the machines (and they wondered why the coolant was Green/Brown/Black, the stink was awful !! ), my last job, no working oil skimmers, they never changed coolant in over 20 years, ( the manager would not allow the time for cleaning/maintenance ) they kept topping up with more coolant, ignoring the stench and build-up of bacteria and rancid way oil everywhere....this was one of the reasons why i quit... Don't be that shop!! Clean and maintain your coolant, get with the 21st century !!!

Hi, should I change my coolant if there is a high bacteria count or is there something else I can do, the same for Yeast ?

My company has 5 mid size Haas machines and I am on the safety committee struggling to learn how to properly collect and dispose of the constant run off. The operators currently have large plastic Foldgers (yep the coffee) cans they have trimmed out a spot for the hose to be fed into. They then dump these can into buckets out back with an aerator to evaporate. Neither container is labeled (OSHA Violation) and I am concerned how to manage. What are some common industry practices for this? Thanks in advance!

Signing into Better MRO is easy. Use your MSCdirect.com username / password, or register to create an account. We’ll bring you back here as soon as you’re done.

Here is a link to our e-commerce site where there is a digital catalog you can look through: https://www.mscdirect.com/ Thanks for your interest

Cutting fluid and its disposal are a necessary expense. Though these costs don’t compare to the expense of an idle CNC machine tool, it’s a good idea to maximize coolant life whenever possible. Shops with a few dozen machine tools might consider a centralized cutting fluid system. In lieu of this, a coolant recycling center is probably the best bet, and use a Shop-Vac or sump doc to bring old cutting fluid back to the reservoir for processing.

To operate any machine efficiently, the machinist must learn the importance of cutting speeds and feeds. A lot of time can be lost if the machines are not set at the proper speed and feeds for the workpiece.

The chips and sludge are displacing coolant, so the volume is ever changing. Keeping the sump clean makes concentration control easier. Monitor pH with a meter (preferred) or test strips weekly—if pH is falling, there’s a good chance that something nasty is growing down there. Time to give the machine a thorough cleaning and install some fresh coolant, preferably using a sump doc.

The feed of a lathe is the distance the cutting tool advances along the length of the work for every revolution of the spindle. For example, if the lathe is set for a .020 inch feed, the cutting tool will travel the length of the work .020 inch for every complete turn that work makes. The feed of a lathe is dependent upon the speed of the lead screw or feed rod. The speed is controlled by the change gears in the quick change gearbox.

Example: Material = Aluminum 3” Cutter, 5 Teeth Chip Load = 0.018 per tooth RPM = 3000 IPS = 0.018 × 5 × 3000 = 270 Inches Per Minute

We make a water-based product from Alpha Biologix called "Quantum Pure" That kills the bacteria in any coolant. We've tested in CNC shops across the country, and in our CNC's running the same coolant for 2 plus years. Coolant goes airborne, and that bacterium is inhaled, gets on the skin and cloths throughout the building. We've treated large systems and small (50) gallons.... Non-chemical, we're just getting started with the sales and marketing efforts. Machinists love it, no more stinky cloths or infections...

1. Do you accept master and visa credit card payment ? 2. Do you accept private pick up by our forwarder ? 3. Can you send me your price sheet or catalog?

Cutting fluids provide lubricity and remove heat from the work zone. As coolant breaks down, the sulfur, chlorine and other extreme-pressure compounds contained within become ineffective. This leads to poor tool and machine life as well as problems with accuracy and part quality.

Performance Micro Tool manufacturers Micro and Miniature End Mills, Drills, and Routers for high performance machining. Sizes range from .0002 up to .125.

Calculate RPM, IPM, SFM, IPT and more. · Variables / Abbreviations · Milling Formulas · Radial Engagement Feed Adjustment Chart.

My husbands wasn't cleaned either. Eventually they started cleaning his machine every six months. Few people at my husbands job had lung issues. Then when the mask mandate went in he was working 10hrs a day with coolant sitting on his mask since his machine sprayed him consistently. Within two months of the mask mandate he broke out with a rash that looked like 2nd degree burns & developed rapid ILD & I almost lost him. The coolant definitely caused the rash & I suspect the ILD also. Unfortunately he can no longer work & currently trying to get on the transplant list for a double lung transplant. Please be careful with this shit. There are studies out of the UK Thats says this shit can cause skin conditions & lung disease.

Dirty metalworking fluids can cause a host of problems for your CNC machining operations, and they can be harmful to machinists if not cared for properly.

For general purpose machining, use a recommended feed rate of .005 – .020 inches per revolution for roughing and a .002 – .004 inches per revolution for finishing.

i would also like to share my experience from shop. We run about a dozen machining centers and some time back we sourced coolant quality continuous monitoring sensors from a company, SciLogic. Since we had some dimensions which would fire if coolant concentrations are off. The system has been sending alarms for concentration drops and trends on ph, temperatures etc. and recommending additions. It has worked wonders. As an owner Didn’t focus on coolant as a contributor to rejections before.

Do you maintain clean coolant? If not, what challenges do you face in keeping it clean regularly? Share your experience.

Kip Hanson is a freelance writer and manufacturing consultant. Hanson, who is the proprietor of KAHMCO LLC, has more than 40 years experience in manufacturing, machine tools, fabrication and ERP systems. In addition, Hanson is a contributing editor at Manufacturing Engineering, Shop Metalworking Technology and others. He has been writing about manufacturing technology since 1998.

4. Feed rate and cutting speed are mostly determined by the material that’s being cut. In addition, the deepness of the cut, size and condition of the lathe, and rigidity of the lathe should still be considered.

The recommended feeds for cutting various materials when using a high speed steel cutting tools listed in table below. For general purpose machining a .005 – .020 inch feed for roughing and a .012 to .004 inch feed for finishing is recommended.

Continuous skimming, monitoring pH and concentration levels, keeping machine tools clean and in top working order—these are all good recommendations that will maximize the life of any metalworking fluid. There comes a time, though, when the machine sump must be removed, cleaned and recharged with fresh coolant. In many shops, this unpleasant task means drawing straws or playing a quick game of rock, paper, scissors to see who gets stuck with the dirty work.

Thread Rolling, Die Production & Servicing · More videos on YouTube · Post navigation · Stay in the loop with the latest news and products.

I can understand how a business could really benefit from making sure that their machines are maintained correctly. It was interesting to learn about how they can optimize productivity by cleaning their equipment, and sump at the end of the day. It could be really useful for them to get the best technical support from a professional to help the machines be more effective. https://kochmachinetool.com/

Manufacturing Processes 4-5 Copyright © by LamNgeun Virasak is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

Find many great new & used options and get the best deals for 1942 Libert Hi-Speed Shear Libert Machine Company Vintage WW2 Print Ad at the best online ...

5. Roughing cuts (0.01 in. to 0.03 in. depth of cut) for most aluminum alloys run at a feedrate of .005 inches per minute (IPM) to 0.02 IPM while finishing cuts (0.002 in. to 0.012 in. depth of cut) run at 0.002 IPM to 0.004 IPM.

It makes sense that your machine might get suffer from rust damages if you do not keep your coolant clean. My uncle is thinking about becoming an industrial worker so that he can make enough money to pay off his car, and he wanted to learn about the importance of coolant in machines. I'll let him know that keeping your coolant clean will ensure that his machines are properly functioning.

And if you have any specific questions, please feel free to post on our forum and our experts will be happy to help! (https://www.mscdirect.com/betterMRO/forums/forums/ask-msc-metalworking-t...) Thank you for visiting Better MRO and sharing your experience!

If you'd like to learn more about coolants, we have several articles here on the Better MRO site: (https://www.mscdirect.com/betterMRO/metalworking/search?t=coolants)

Mar 10, 2017 — You are not supposed to drill hardened steel. That's why it is hardened, to prevent jerks from making holes in it. EDM or maybe diamond abrasive if time is not ...

Jan 16, 2013 — Carbide inserts, the standard choice for most machining operations, can be used at the lower range of hardness (45 to 50 HRC), but at much lower ...

The KF 20 L is ideal for drilling, milling and countersinkin... 1.130,40 € incl. 20% VAT 02 1015 1 KF 20 Super The milling machine KF 20 Super features a ...

From dermatitis to decreased tool life, clean coolant is simply better and makes for happier machinists and a more productive shop floor.

Micro Thread Mills are cutting tools that are specifically designed to produce fine, intricate threads in small workpieces. With their precise cutting geometry, ...

If you were cutting thread all day long: day in and day out. You might set the lathe up for only two cuts. One cut to remove all but .002 or .003 of material and the last cut to hold size and finish. This is done all the time in some shops today.

“Machine life suffers from dirty coolant: That’s a true statement,” says Brumgard. “Fluid will attach itself to the workpieces, but also to the chips and the dirt, and so you have to monitor coolant for all these things.”

To be fair, even freshly mixed cutting fluids contain a host of chemical additives such as biocides, emulsifiers, corrosion inhibitors, anti-foaming agents and more, any of which can cause skin irritation, rashes and dermatitis. When cutting fluid is neglected, the concentration of these chemicals may reach unsafe conditions. Also, an improperly maintained machine tool sump becomes a perfect breeding ground for microbes.

Machinist coolantnear me

You need to let the tank dry; then thoroughly clean the tank and system with cleaner. then add new coolant. Do you use filters and a centrifuge or skimmer? Check the PH and concentration regularly, and provide regular maintenance.

Hi! info is great. we have been having issues with our coolant for a couple of years. We had the coolant company come in to help us figure it out. The problems are a strong stench, dirty socks smell we can't get rid of. Burning sinus and possible skin iritants. Coolant caking on top layer turning brownish with white and black spores on surfaces. They tested ph it was good. they took samples from differnt machines. They said no bacteria or microbes/ mold. Gave us bacticide to add anyways. With no changing to the problems. In one machine we switched coolant to hocut 795-H after running cleaner in the machine provided by the supplier. Previous coolant was hocut ws 8800. Which is still in other machines. Good for a few weeks smell came back. We installed disk skimmers on the cnc machines. It's better but still having build up on the surface. Coolant is white or milky when fresh. Changing to light brown grey on the surface. In the other machines coolant is green when fresh. It has been changing black on the surface. Coming out of the skimmer it's black and oily texture. In the new white coolant of the skimmer is light to really dark grey. We have gotten another coolant valcool vp 800 pm to posibily try next. Running low on solutions. The coolant tank has a chip seperator so this area is not circulating from the skimmer. Not sure if the fish pump is the way to go. Do you have any recomendations? Concentrations are all over the place. Were trying to create a maintence plan and we have ph strips to check weekly. Just started today. Please help!!!

I have issues with fine swarf in the coolant system coming back through and creating a fine build up on the machine surfaces and Tooling any ideas to remedy this?

The feed of on lathe, or the distance the carriage will travel in on revolution of the spindle, depends on the speed of the feed rod or lead screw. This is controlled by the change gears in the quick-change gearbox. This quick change gearbox obtains its drive from the head stock spindle through the end gear train. A feeds and thread chart mounted on the front of the quick-change gearbox indicates the various feeds and metric pitches or thread per inch which may be obtained by setting levers to the positions indicated.

Have you noticed that when you take a very small cut on the lathe .001 to .002 that the finish is usually poor, and that on the rough cut you made prior to this very light cut, the finish was good? The reason for this is: some tool pressure is desirable when making finish cuts.

See how Master Fluid Solutions significantly improved the low-foaming characteristics of one of their TRIM® cutting fluids.

They are usually recognized as irritated skin, but what has happened is these tiny cuts have allowed the coolant to cause even more irritation due to broken skin. Bottom line: The dirty coolant has become abrasive to the skin and leaves it more susceptible to irritation, Brumgard asserts.

0086-813-8127573

0086-813-8127573