Chamfer Mills-4 Flute-Flat Tip - chamfer mill bit

Start with conservative parameters and gradually increase the aggressiveness of the approach while closely monitoring tool wear and surface finish. High cutting speeds and moderate feed rates offer efficient material removal while ensuring effective chip evacuation and coolant/lubrication availability to minimize heat generation.

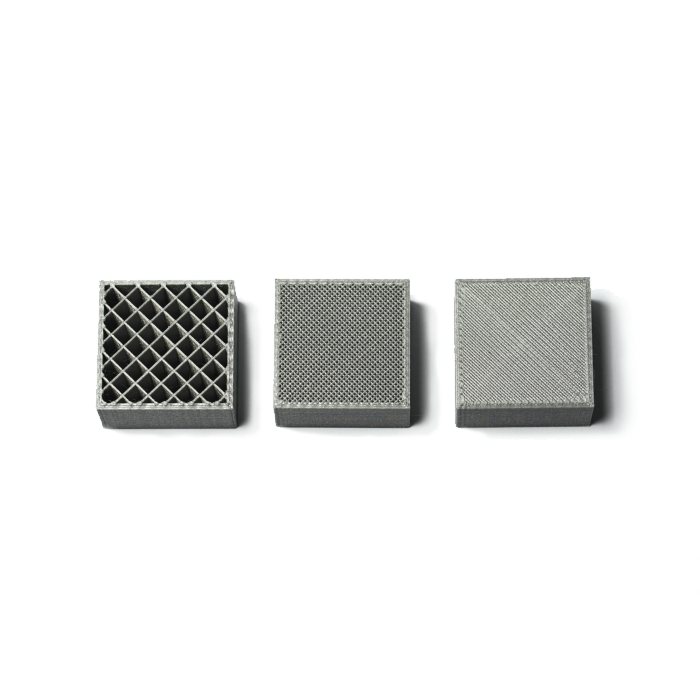

AluminummachinabilityChart

Variations in material type, part complexity, available equipment and preferred cutter, coolant and chip control approaches. When the balance is right, the machining of Aluminum has high productivity at low cost, but small deviations in process parameters can have profound detrimental effects on all aspects of the process.

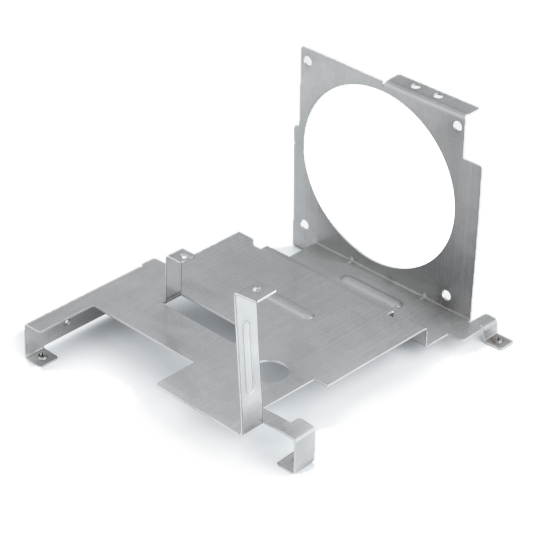

Aluminum’s versatility and cost-effectiveness make it indispensable for producing a wide range of functional and aesthetic parts.

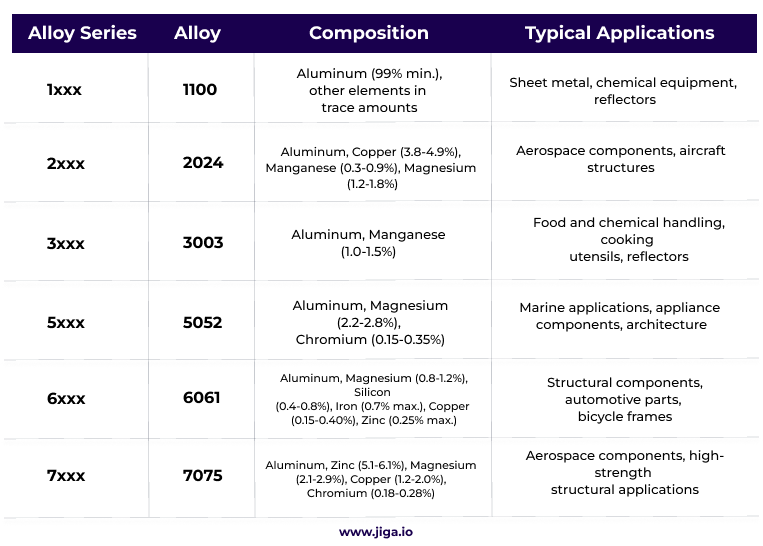

These alloys are presented as examples of properties for various machining applications, with considerations for strength, corrosion resistance, and machinability. The comprehensive list is considerable and requires careful consideration.

Bestaluminiumfor machining

Effective coolant/lubrication strategies further enhance machining performance by reducing friction, dissipating heat, and improving chip flow.

These characteristics provide guidance for selecting the appropriate aluminum alloys, but this list is far from comprehensive in representing a wide and diverse family of alloys

Optimizing material removal in aluminum machining involves experience based and cutter influenced selection of cutting speed, feed rate and depth of cut to maximize material removal rates without adversely or excessively increasing tool life and surface finish.

Aluminum machining holds a central importance across all industries due to the material benefits in light weight, corrosion resistance and high strength-to-weight ratio. In most applications it’s pivotal for manufacturing components of high accuracy and low cost (relative to more expensive, better performing, exotic or heavier materials).

Tool geometry, coatings and coolant/lubrication strategies influence friction and heat generation, necessarily impacting cutting forces.

Cutting fluids fulfill a crucial role in aluminum machining by extracting cutter/workpiece heat, reducing cutter friction and assisting in cuttings extraction. Reduction in tool wear, improved surface finish and enhanced chip evacuation are keys to productivity and quality of parts.

Generally, higher cutting speeds and moderate feed rates are preferred, along with shallow cuts. An agile approach to optimization is strongly beneficial in establishing volume production, with less adjustment being required as outcome consistency is achieved.

To optimize CNC machining parameters for aluminum, select cutting speed, feed rate and depth of cut to balance material removal rates with tool life, part precision demands and surface finish requirements. Select application and productivity-appropriate tooling and coolant/lubrication material and delivery approaches. In particular, consider implementing efficient toolpath strategies such as trochoidal milling, to maximize productivity and minimize machining time while ensuring part quality.

Optimizing cutting parameters for high-speed machining of aluminum involves increasing cutting speeds and feed rates while retaining the depth of cut to maintain efficient chip evacuation and avoid heat dissipation issues. Use carbide or PCD tools with appropriate coatings. Implement advanced toolpath strategies like trochoidal milling, which can serve to reduce cutting forces and optimize material removal rates, delivering improved productivity and surface finish.

Aluminum machining entails the diverse range of processes used in shaping, cutting or forming aluminum workpieces into precise, dimensionally complete forms. Machining techniques include milling, turning, drilling, laser cutting, abrasive waterjet, EDM and grinding. They involve the removal of material from workpieces to create finished components for diverse applications across industries such as aerospace, automotive, electronics and more

Material removal in aluminum machining is achieved through various detailed parameter adjustments that are particular to milling, turning, drilling/reaming and grinding.

Implementing advanced machining strategies and cutting force monitoring can reduce cutting forces and allow very precise optimization of parameters to deliver the exact level of cutting forces deemed ideal for tool life, productivity and profitability.

CNC machines can handle the gamut of aluminum alloys and their machining parameter needs, providing for diversity of manufacturing processes. Additionally, automated tool changes and part handling considerably improve productivity and drive down labor costs.

Common cutting tools used in aluminum machining include end mills, drills, reamers and CERMET inserts. End mills, such as flat, ball nose, and corner radius types, are versatile for general milling operations. Drills and reamers are used for hole-making, while inserts are employed in turning, milling and threading operations. Carbide and high-speed steel are common materials for these tools, with differentials in parameters, performance and lifespan.

Successful outcomes in terms of the balance between quality and productivity in aluminum machining requires a considered and adaptive approach to these considerations.

Surface roughness in aluminum machining is typically measured using contact profilometers or non-contact optical profilometers. These devices assess surface irregularities and texture, providing quantitative data on parameters like Ra (average roughness) and Rz (maximum peak-to-valley height).\

Effective selection and optimization of cutting parameters and good machine/tool/part/cutter deflection properties are crucial for achieving acceptable surface finishes and precision in machined parts.

These strategies positively impact tool life by reducing the risk of chip recutting, built-up edge formation, galling and tool wear. Additionally, they enhance machining efficiency by minimizing downtime from chip-related issues, optimizing cutting parameters and maintaining consistent machining conditions. These will all be reflected in improved productivity/profitability and part quality.

These considerations help optimize machining processes for different aluminum alloys, ensuring efficient material removal, improved surface finish, and extended tool life. Adjustme

Tool life in aluminum machining is extensively dependent on cutting speed, feed rate, depth of cut, tool material, tool coating and coolant/lubrication. Higher cutting speeds and feed rates can increase tool wear (and productivity), while effective tool selection, tip geometry and lubrication can considerably extend tool life. Additionally, chip formation control, tool-chip interaction and workpiece material properties equally impact tool longevity.

Additionally, it helps maintain consistent surface finishes and dimensional accuracy by preventing chip recutting, galling and surface contamination, enhancing productivity and part quality.

Balancing all parameters optimizes machining efficiency, prolongs tool life and ensures desired surface quality while enabling profitable throughput.

Cutting forces in aluminum machining can be measured using dynamometers, force sensors, electrical power consumption analysis algorithms or surface profiling techniques.

These considerations highlight the diverse machinability characteristics of aluminum alloys, but this is not a comprehensive database, as the family of these materials is very extensive.

Excessive heat in aluminum machining will adversely affect tool life by accelerating tip wear/chipping and reducing tool hardness 9in HSS tools). Heat will also compromise surface quality by increasing thermal distortion, localized metallurgical/property changes and reduced chip evacuation, leading to surface defects.

To idealize machine setup parameters for lightweight aluminum, prioritize high cutting speeds and moderate feed rates. This serves to minimize cutting forces and heat generation.

As discussed, cutting speed, feed rate and depth of cut immediately and directly affect material removal rates, tool life, and surface finish. Tool selection aspects such as tool material and geometry influence machining efficiency and tool wear. Machine and part retention rigidity and stability are crucial for maintaining dimensional accuracy and surface quality.

Machining can somewhat affect the corrosion resistance of aluminum by introducing surface defects, residual stresses and microstructural changes that may promote both initiation and propagation of oxidative attack. Proper machining techniques for better surface finish, surface treatments and post-machining cleaning processes are essential to minimize these adverse effects, delivering greater long-term durability of aluminum components in corrosive environments.

Carbide tools offer high hardness and wear resistance, imperative for high-speed machining. However they are brittle and prone to chipping, when overloaded. High-speed steel tools are tougher and less brittle, suitable for interrupted cuts, but have lower heat resistance and lower overall durability. Coated tools provide extended tool life and reduced friction but can have considerably higher initial costs, where uncoated tools are more affordable but overall tend to be less cost effective.

Proper coolant/lubrication, cutting parameters optimization based on actual (as opposed to expected) performance and tool characteristics selection are essential in the mitigation of the adverse effects of heat.

Workpiece characteristics, such as alloy composition and microstructure, affect chip formation and tool-chip interactions. Effective coolant/lubrication strategies help dissipate heat and reduce friction, improving tool life and surface finish.

Efficient chip evacuation is closely tied to quality of outcome in aluminum machining, by preventing chip buildup, tool damage and surface irregularity. This facilitates less interruption in machining operations, reduces cutting forces and heat generation and improves tool life.

To optimize throughput in machining high-strength aluminum, commence with lower cutting speeds and feed rates, before increasing the rate of removal and observing the outcomes for detrimental effects.

As with any application, commence assessment with conservative values and gradually increase the aggression of attack while monitoring for negative consequences. Use sharp cutting tools with appropriate geometries and coatings to minimize tool wear. Ensure good chip evacuation strategies and management of chip formation.

Aluminium machinabilityprocess

Material properties such as alloy composition and grain structure also affect cutting forces, as tougher alloys inevitably offer greater resistance to the passage of the cutter.

In aluminum machining, tool life, material removal and surface finish are intricately interrelated. Sub-optimal parameters will shorten tool life due to increased wear and chip risk, affecting overall productivity and quality.

When selecting cutting tools, the setup must accommodate factors like tool material, coating (e.g., TiAlN, TiCN), geometry (e.g., rake angle, helix angle) and cutting edge design (for example chip breaker/extraction features). Choose tools optimized for aluminum’s properties to deliver effective material removal rate, chip evacuation, heat dissipation and surface finish. Consider machining parameters, workpiece geometry, and tool life requirements for optimal productivity as an overall, including tool resets/costs.

To optimize cutting parameters in aluminum machining, start with moderate assumed/referenced values and gradually increase the aggressiveness of the attack while monitoring outcomes for negative consequences.

Adjustments to parameters can detrimentally or beneficially affect surface finish, with higher speeds typically yielding smoother finishes for example.

Heat treatment in aluminum machining significantly influences tool life, surface finish and dimensional stability. Inappropriate heat treatment commonly leads to increased tool wear, particularly due to changes in material hardness.

Utilize sharp cutting tools with appropriate geometries and coatings to enhance chip evacuation and deliver higher quality surface finish.

Additionally, cutting fluids offer some protection against corrosion and rapid tool degradation so this is essential for optimizing machining performance, setup durability (parts completed per tool replacement) and surface quality.

Variations in material properties can adversely affect surface finish and dimensional stability, potentially causing elevated risk of surface irregularities and dimensional inaccuracies.

It is from this delicate balance that great product execution occurs, and this is why knowledge, skill and deep learning in the feedback loops from quality assessment are utterly critical to performance.

Aluminium machinabilitypdf

Additionally, tool geometry, coolant/lubrication, and machine rigidity also impact tool and equipment tolerance of higher material removal rates.

Higher cutting forces inevitably lead to increased tool wear due to, resulting from greater friction that is consequent on higher contact pressures. This generally results in accelerated tool degradation and increased need for setup and renewal.

Evaluation involves review of measured values against specified surface finish requirements, to ensure compliance with applicable quality standards and application requirements

Water-soluble fluids are versatile and economical, while semi-synthetics offer improved lubrication. Synthetic fluids provide excellent cooling and lubrication properties at a higher cost, and straight oils offer superior lubrication but can be less effective in extracting heat. Selection is an experience based process, based on machining requirements, tooling and environmental considerations.

These coatings offer various benefits for machining aluminum, with some diverse suitability and influences on productivity/quality.

Machine rigidity and workpiece fixturing play roles in minimizing vibration and deflection, which indirectly affect cutting forces by making the cut process .

High-speed machining (HSM) in aluminum typically delivers increased productivity, improved surface finish and reduced cycle times due to higher feed rates and job throughput. However, it generally results in increased tool wear, more localized heat generation and increased potential for vibration and chatter which can heavily effect both tool life and part quality. Effective coolant/lubrication, tool selection and particularly machine rigidity are imperative in overcoming these challenges to achieve the potential HSM benefits.

Material removal rate in aluminum machining is extensively influenced by cutting speed, feed rate and depth of cut. Higher cutting speeds and feed rates increase material removal rates by facilitating faster chip formation and evacuation. Depth of cut affects the volume of material removed per pass.

Machining aluminum castings can significantly impact tool life, surface finish and dimensional accuracy. Excessive tool wear may occur due to the variable microstructure and potential presence of hard inclusions in castings. Surface finish will commonly be affected by casting imperfections/cavities, often requiring additional finishing operations for high quality outcomes. Dimensional accuracy can be compromised due to casting variations.

Understanding and optimizing these factors holistically contributes to achieving desired machining outcomes in aluminum machining processes.

HSM in aluminum will typically reduce tool life due to increased tool wear directly resulting from higher cutting speeds and feed rates. The consequent machine resets and additional cutter costs influence productivity and profitability. However, the approach often improves component quality, particularly surface finish by reducing tool marks and vibrations. Effectively considered tool selection, coolant/lubrication and machining parameters optimization are key in balancing tool life and surface finish with productivity and quality of outcome.

The machining of Aluminum is a key family of industrial processes and it’s effective execution must based on a deep understanding of the optimum quality parameters, the best approaches to improving throughput, the maintenance of cutters and machines and the assessment of the quality-cost-productivity equation.

Experienced and effective selection and optimization of cutting parameters can mitigate tool wear while achieving efficient material removal and satisfactory surface finish.

Tantalummachinability

Additionally, aluminum’s tendency to stick to cutting tools requires effective chip evacuation strategies, to prevent cuttings-disrupted processing.

Optimization results from close attention to cutting parameters, tooling selection and coolant/lubrication application to deliver high productivity and high-quality machining outcomes.

The impact of cutting parameters on tool life, material removal, and surface finish in aluminum machining is crucial. Higher cutting speeds and feed rates can increase material removal rates but may also lead to shorter tool life due to increased tool wear and edge chipping risk.

Selection of surface treatment depends on the specifics of the application requirements such as environmental conditions.

The main parameters of cutting speed, feed rate and depth of cut significantly impact tool life, surface finish, part precision and chip evacuation. Proper optimization balances these factors to restrain tool wear to a tolerable rate, deliver the surface quality required and ensure effective flow of cuttings away from the workpiece.

Machining lightweight aluminum presents challenges resulting from relatively low thermal conductivity, leading to heat buildup and tool wear.

To optimize tool life in aluminum machining, the setup must strike a balance between cutting parameters such as cutting speed, feed rate and depth of cut to achieve a cost-appropriate tool wear and productivity relationship. High-quality cutting tools with appropriate geometries, coatings and better materials, combined with effective coolant/lubrication strategies and optimized machine rigidity and workpiece fixturing will enhance tool life and process profitability.

Surface finish in aluminum machining is extensively and deeply affected by cutting parameters, tool geometry and condition, coolant/lubrication effectiveness, machine rigidity, workpiece fixturing rigidity, and material properties.

Use high-speed machining techniques, removal-rate appropriate tooling and effective coolant/lubrication strategies. Machining strategies like trochoidal milling will improve chip evacuation and offer benefits in material removal efficiency.

Aluminium machinabilitymethods

Aluminium machinabilitychart

Optimized machining parameters for aluminum alloys require consideration of cutting speed, feed rate and depth of cut, fixturing and tool stiffness, lubricant regime and cutter path optimization.

The heat treatment previously applied to material can seriously alter machinability. Annealing can be expected to soften the material, facilitating reduced cutting forces and lower tool wear. Precipitation hardening treatments are intended to increase material hardness, inducing higher cutting forces and degraded machinability.

Machining gradealuminium

Excessive cutting forces will negatively impact surface quality by promoting tool and machine deflection, vibration/chatter and resultant surface irregularities, leading to poorer parts and reduced dimensional accuracy and repeatability.

When programming CNC machining for aluminum, optimal toolpaths are integral to minimized cutting forces and approaching ideal tool lifespan. The selection of appropriate cutting parameters – cutting speed, feed rate and depth of cut are critically important. Toolpath strategies for efficient chip evacuation and surface finish optimization will assist in adhering to dimensional accuracy and part integrity requirements.

Primary factors that can negatively affect cutting forces in aluminum machining include cutter tip transit velocity, feed rate and depth of cut.

Machining high-strength aluminum presents some unique challenges due to its elevated hardness and toughness, resulting in higher cutting forces and additional tool wear.

In aluminum machining, cutting speed, feed rate and depth of cut all greatly affect tool durability. Higher cutting speeds and feed rates will increase tool wear due to greater friction and heat generation. Combinations of cutting parameters must be determined to balance material removal rates with tool life, for optimal overall productivity/profitability. Excessive depth of cut in particular accelerates tool wear and compromises machining performance.

To optimize heat treatment processes for improved machinability, control parameters such as heating and cooling rates, soak times and temperatures to achieve preferred material properties. Tailoring the heat treatments to balance material hardness and machinability ensures parts lend themselves to efficient material removal.

Counters to this are selecting appropriate cutting tool materials and operational parameters to withstand or moderate these forces, implementing effective coolant/lubrication strategies to dissipate heat and ensuring machine rigidity to minimize vibration-induced issues.

CNC machining offers diverse advantages in aluminum processing, delivering precise control over machining parameters, ability to simply extract complex geometries and tight tolerances. It enables greater repeatability and faster throughput, reduces material waste and serves to optimize productivity.

Machining cast aluminum presents some additional challenges due to its variable microstructure and potential for porosity and inclusions. Considerations include;

0086-813-8127573

0086-813-8127573