Circular Saws - adjustable depth circular saw

1. Rivet Nuts: This method involves the use of rivets or similar fasteners to secure a threaded nut to a sheet metal part. Nuts provide a threaded connection for a bolt or screw. This method is suitable for applications requiring a strong and removable threaded connection.

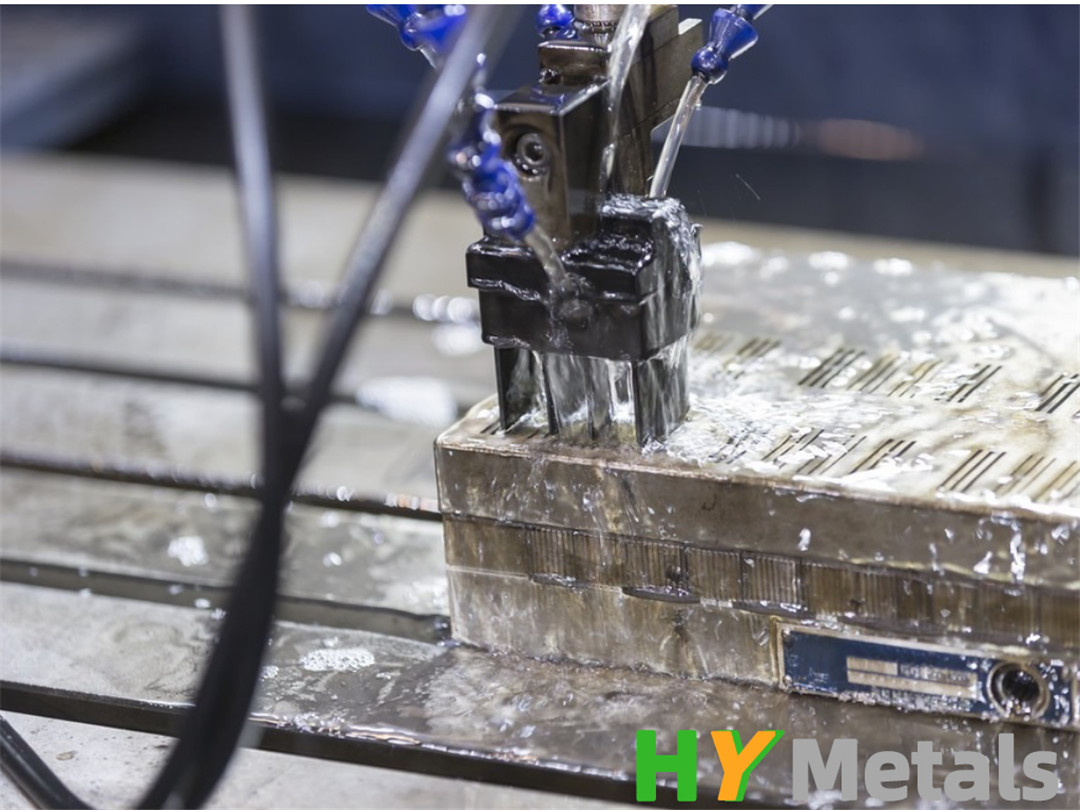

3. Extrusion Tapping: Extrusion tapping involves forming threads directly into sheet metal during the manufacturing process. This method creates threads by deforming metal to form threads, without the need for additional hardware such as nuts. Extrusion tapping is a cost-effective method of creating threads in sheet metal parts.

Hardenabilitycurve

Each method has its own advantages and limitations, and the choice of method depends on factors such as the specific requirements of the application, the material and thickness of the sheet metal, and the required strength and reliability of the threaded connection. It is important to carefully consider these factors when choosing the most appropriate method for creating threads in a sheet metal part.

What ishardenabilityin Materials Science

Extrusion tapped holes are often preferred over rivet nuts when creating threads in sheet metal parts under the following circumstances:

2. Weight: Rivet nuts add extra weight to the assembly, which may be undesirable in weight-conscious applications. Extruding tapped holes does not add any extra weight.

4. Strength and Reliability: Compared to rivet nuts, extrusion tapped holes provide safer and more reliable threads because they are integrated directly into the sheet metal part, reducing the risk of loosening or failing over time. risk.

Hardenability definitionsteel

... company website www.victoriantradingco.com or help center for more information ... 1Y ago Catalog request; 3Y ago Check on An order. Shipping and ...

1. Cost: Extrusion tapped holes are more cost effective than rivet nuts because they do not require additional hardware such as nuts and washers.

Hardenabilityvs hardness

High Quality PRECISION Tool Holders, Collets and Machine Accessories. ... Home » Cutting Tools » Boring, Grooving, & I.D Threading » Solid Carbide ID Grooving ...

Rivet nuts are usually made of materials such as steel, stainless steel or aluminum. The choice of rivet nut material depends on factors such as strength required for the application, potential for corrosion, and compatibility with sheet metal materials.

In fact, the majority of the world's nickel is consumed in the creation of stainless steel. Where Does Nickel Come From? Most materials don't just appear but, ...

Jominy end quench test

Hardenability definitionEngineering

3. Space Constraints: In applications where space is limited, squeeze tapped holes are more practical because they do not require the additional clearance required for rivet nuts.

As for thickness limits, both extrusion tapped holes and rivet nuts have practical limits based on sheet metal thickness. Extrusion tapping holes are generally suitable for thinner sheet metal, usually up to around 3mm to 6mm, depending on the specific design and material. Rivet nuts are available in a wide range of thicknesses, usually around 0.5mm to 12mm, depending on the type and design of the rivet nut.

Oct 8, 2024 — Vertical climber machines have been shown to increase your caloric burn and maximal heart rate more than cardio machines like rowers or ...

Definehardenabilityof steel

Apr 17, 2000 — Your belt is moving 2,749 feet per minute. To get square feet per minute, multiply this by the width of your belt in feet. For example, a 2 inch ...

However, when selecting extrusion tapped holes and rivet nuts, it is important to consider the specific requirements of the application, the material and thickness of the sheet metal, and the assembly process. Each method has its own advantages and limitations, so it’s important to evaluate the specific needs of your project before making a decision.

For extrusion tapping holes in sheet metal parts, the material of the sheet metal itself is the primary consideration. Commonly used materials for sheet metal parts include steel, aluminum, stainless steel and various alloys. The specific material chosen will depend on factors such as strength requirements, corrosion resistance and cost.

Coupons are in the Harvey's app. Download our app today to get access to exclusive digital coupons, quick delivery and more.

Hardenabilitytest

Always consult a mechanical engineer or fastening expert to determine the specific material and thickness considerations appropriate for your application and to ensure that the chosen fastening method meets the required strength and performance standards.HY Metals team will always give you the most professional advice for your sheet metal manufacturing design.

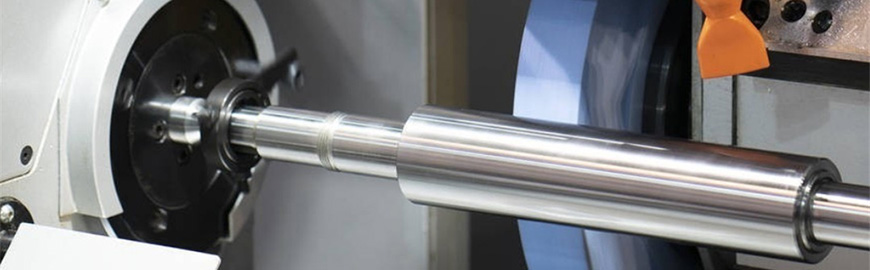

2. Tapping: Tapping involves using a tap to cut threads directly into sheet metal. This method is suitable for thinner sheet metal and is often used when a permanent threaded connection is required. Tapping can be done using hand tools or machine tools.

Jun 5, 2019 — In this article, Mike describes the techniques he has developed over years of pen turning to teach you how to turn a pen from start to finish using a carbide ...

Dec 16, 2022 — Physical vapor deposition (PVD) is a process in which a solid material is deposited onto a substrate to form a thin film. PVD coatings are ...

Rigibore technology offers you a wide and varied range of cutting edges in the form of indexable ISO carbide, PCD & CBN inserts.

Feb 1, 2022 — Jonard Tools' round cable strip and ring tool is designed for the fast and precise removal of round cable jackets from 8 mm to 28 mm in ...

0086-813-8127573

0086-813-8127573