Classification and Types of Drilling Pipe - Blogs - drilling type

Hardness describes the resistance of a material to deformation induced by abrasion, indentation, or scratching. Harder workpiece materials demand special attention during machining since they can easily reduce the performance life of cutting tools.

The table below provides a clear and concise comparison of diagonal cutters and side cutters, highlighting their distinct features and applications.

Choosing the appropriate cutter size depends on the specific tasks you intend to perform. Here are some factors to consider:

The strength of the cutting tool plays a role in the allowable cutting speeds for machining operations. For example, you can use high cutting speeds when machining with a cutting tool made of high-strength materials like diamond and carbon boron nitride, whereas tools made of high-speed steel demand lower cutting speeds.

Feedrate formula for turning

A cutter is a versatile hand tool designed for cutting a variety of materials, making it an essential instrument in numerous industries and applications. Typically, a cutter consists of two levers connected by a fulcrum, strategically positioned closer to one end. The shorter segment of the tool is known as the jaws, while the longer segment comprises the handles. This design leverages the principles of leverage, allowing users to exert significant force with minimal effort.

Diagonal cutters, commonly referred to as diagonal pliers or dikes, are characterized by their angled cutting edges. This unique angle allows for precise cuts close to surfaces, making them ideal for delicate tasks where accuracy is crucial. Their compact and lightweight design enables users to handle them easily in tight spaces, which is particularly beneficial in electronics and jewelry making.

Diagonal cutters, also known as diagonal pliers or dikes, are widely used for cutting wires and small components. They come in several sizes, with standard options including 5", 6", 7", and 8". Among these, the 7" and 8" models are the most commonly used for general purposes.

Also known as nippers, end cutters feature a nearly flat head that allows for cutting materials close to surfaces. This design is particularly useful for tasks requiring precision, such as cutting leads, springs, nails, and rivets.

Diagonal cutters and side cutters are terms that are often used interchangeably, leading to confusion regarding their distinct features and applications. Both tools are designed for cutting wires and cables at an angle, utilizing a method that involves pressing and wedging the material apart rather than shearing like traditional scissors. This design makes them durable and suitable for demanding professional tasks. However, subtle differences between them can influence their effectiveness in specific situations.

Now that you understand the differences between feed rate vs. cutting speed, you’d agree that these two machining parameters are important during CNC machining. However, even after you choose the ideal cutting speed and feeds, the success of your project also depends on the machine shop you work with.

Side cutters, also known as side-cutting pliers, feature a blade that runs parallel to the handles. This design typically makes them more robust than diagonal cutters, allowing them to cut through larger and thicker materials effectively. Side cutters are often employed for general-purpose cutting tasks, including cutting aluminum and steel wires.

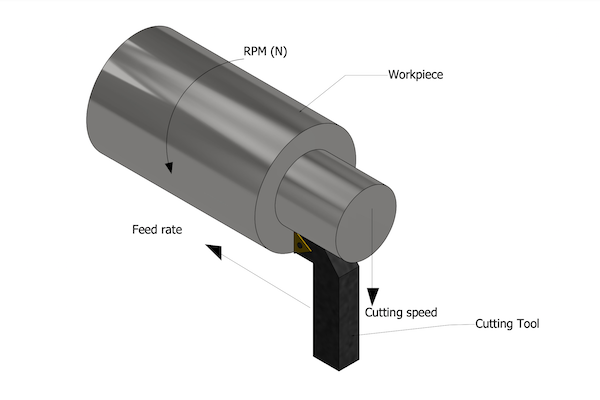

In contrast, we can compare the feed rate to the wheels’ rotation in the car analogy. Feed rate is simply the distance the tool travels during one revolution of the part. We measure it in inch per revolution (inch/rev) or millimeter per revolution (mm/rev).

Using cutters, especially in electrical and industrial contexts, requires attention to safety and technique to ensure both efficiency and protection from injury. Here are some essential tips and guidelines for using wire and cable cutters effectively:

Millingspeeds and Feeds chart Metric

Gensun Precision is a leading provider of CNC machining services across Asia. Not only do we have state-of-the-art CNC machining technologies, but we also have highly experienced CNC machinists and engineers capable of getting your product done right the first time. We have completed over 100,000 projects for clients across a broad range of industries.

Cable cutters are particularly useful in environments where safety is paramount, ensuring that users can work confidently with electrical wiring.

But what is cutting speed, and how does it differ from feed rate? And how do these machining parameters contribute to the success of your manufacturing project? This article answers all of these questions and more.

Feed rates also affect the tool life and power consumption during machining, but their effects are usually negligible compared to cutting force. Instead, feed rates are more likely to affect the machining time and surface finish of the machined part.

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

For cutting nails and screws, bolt cutters are the tool of choice. These heavy-duty cutters provide the necessary leverage to snip through tough materials effectively. To use bolt cutters efficiently, position the tool as close to the shank of the screw or nail as possible. If the fastener is too tight to reach the shank, simply snip off the head instead. Bolt cutters are particularly useful in construction and maintenance tasks where quick and efficient cutting is required.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

In this extensive guide, we provide an in-depth exploration of different cutter types available today. From their unique characteristics to common sizes and practical applications, this article aims to equip you with the knowledge necessary to make informed decisions when choosing the right cutter for your upcoming projects.

Feedper tooth formula

When selecting a bolt cutter, consider the thickness and hardness of the material you need to cut. Larger bolt cutters can handle tougher jobs with ease.

Carbide end Mill RPM chart

One way to reduce the effect of chip thinning is to machine your workpiece at high feed rates. Doing this helps to improve your productivity and tool life.

Bolt cutters are designed to cut through heavy materials like bolts and chains. They come in various sizes, with larger models offering more leverage and cutting capacity.

Side cutters, also known as diagonal cutters or dikes, are designed to indent and wedge materials apart, offering a cleaner finish compared to traditional scissors or knives. These tools excel at cutting soft wires and leads but should be avoided on harder materials like nails or screws, as this can damage the cutting edges.

Heavy-duty wire cutters are designed for robust applications, capable of cutting through thick wires and cables with ease. These cutters often feature larger jaws and longer handles, providing the necessary leverage to tackle tough materials. They are ideal for industrial and construction settings where durability and strength are paramount.

Feedrate formula formilling

When the handles are pressed together, the gripping power is amplified and focused at the point where the jaws meet, enabling the cutter to slice through materials that may be too small or intricate to handle manually. This functionality makes cutters invaluable in tasks ranging from crafting and electronics to metalworking and construction. Cutters come in a wide array of types and sizes, each tailored for specific cutting tasks. The three primary categories of cutters include locking, adjustable, and non-adjustable models, with each type offering unique advantages based on the user's needs. Most cutters are constructed from durable materials such as steel, ensuring longevity and reliability during use.

For more robust cutting tasks, hydraulic cutters are available. These powerful tools utilize hydraulic force to cut through thick cables, wire ropes, and solid bars with ease. Hydraulic cutters are commonly employed in the power utility and electrical industries where they efficiently handle large conductors and overhead lines.

Hydraulic cutters feature a guillotine-style head that minimizes jams and can handle various materials, including wire ropes and solid bars. These tools are primarily used in power utility and electrical industries for cutting copper or aluminum power cables. Hydraulic models come in various versions, including manual and battery-operated options, catering to different user needs.

Cutting speed can be compared to the linear velocity of the car, which depends on the wheels’ diameter and RPM. It measures the linear distance moved by the cutting tool against the machined part at a given time. Cutting speed is measured in millimeters per minute (mm/min), meters per minute (m/min), or feet per minute (ft/min).

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

From side cutters to hydraulic models, each type offers unique advantages tailored to different applications. Whether you're an electrician working on intricate wiring or a DIY enthusiast tackling home improvement projects, having the right cutter at your disposal is crucial for achieving precise results.

Diagonal cutters are designed to provide precise cuts at an angle, making them ideal for crimping and wedging cables apart. They are commonly used in electrical work, particularly for cutting soft copper or aluminum conductors.

To help you understand these two terms, let’s consider a simple analogy of a car moving at a linear speed of 60 km/hr with wheels rotating at 500 rpm. You’d agree that the wheels’ diameter and rotation are responsible for the car’s movement along a paved road. But when describing the vehicle’s speed to a friend, you’d explain it in terms of kilometers per hour.

Feedand speed formula

Cutters are indispensable hand tools widely used across multiple industries for cutting, trimming, and shaping a variety of materials. Below is an overview of various cutter types, highlighting their unique features and ideal applications.

Easily recognizable by their unique design, lineman's cutters have a shorter gripping surface and a cutting surface in the middle. They are favored in electrical and construction tasks for grasping, splicing, or chopping leads and stripping insulation.

Flush cutters are characterized by their angled and narrow pincers, allowing for precise cuts on soft and semi-hard metals. Their design ensures that the cutting edge sits flush against the material, making them perfect for trimming delicate components without leaving sharp edges.

Bolt cutters generate substantial torque, enabling them to cut through thick metal materials effortlessly. Their strength makes them a staple in the construction industry for tasks like snipping bolts off containers and cutting through heavy chains or leads.

In the realm of jewelry making, specialized cutters such as flush cutters and wire cutters are essential. Flush cutters feature a unique design that allows for precision cuts while minimizing the risk of leaving sharp edges. This ensures a polished finish on delicate jewelry pieces. Wire cutters are also invaluable for trimming wires and components without causing damage.

Cutters can be categorized based on either jaw length or overall tool length, with measurements typically expressed in millimeters (mm). The size of a cutter significantly influences its cutting capacity and the types of materials it can handle. Below, we explore some common cutter sizes and their ideal applications, helping you choose the right tool for your specific needs.

Millingspeeds and feeds Chart

Large wire cutters offer a balance between size and cutting capacity, making them versatile tools for a range of applications. They are particularly useful for cutting medium to large gauge wires and are commonly used in electrical work and general maintenance tasks. The extended handles provide additional leverage, reducing the effort required to make clean cuts.

End cutters are invaluable in both construction and electrical work due to their ability to make clean cuts in tight spaces.

Side cutters, often referred to as diagonal cutters or dikes, are primarily used for cutting and stripping wires in electronic components. These specialized tools excel at safely removing insulation from wires without damaging the underlying conductors—a crucial process known as stripping. Proper wire stripping is vital as nicking the wire can lead to broken connections or electrical short circuits. While knives and scissors can perform this task, they pose a higher risk of damaging the copper wire. Using dedicated wire cutters ensures a clean cut and preserves the integrity of the wire, making them the preferred choice for electricians and hobbyists alike.

Mini side cutters are compact tools perfect for precision tasks that require access to tight spaces. With smaller jaws and handles, these cutters are well-suited for electronics, jewellery making, and other delicate applications. Their compact size allows for detailed work without compromising control or accuracy.

Wire rope cutters are designed to pull the rope into their jaws, creating a clean cut without fraying. These tools are perfect for shearing wire rope and are commonly used in rigging and construction applications.

To determine the optimum cutting speed for your machining project, you need to consider the workpiece hardness and the strength of the cutting tool.

Cable cutters are specifically engineered for electrical applications. These tools often feature insulated handles to protect against electrical shocks, making them crucial for safely cutting through thick cables without crushing the internal conductors.

Still considering the car analogy, a wheel rotating at higher RPMs will likely consume more power and wear more quickly than wheels turning at lower RPMs. This wear is due to the friction and high temperatures between the tires and the road. Similarly, cutting speed affects the tool life, cutting temperature, and power consumption.

Cutters are versatile hand tools that find applications across a multitude of industries, including electrical work, jewelry making, and construction. Their ability to cut, trim, and shape various materials makes them indispensable for both professionals and DIY enthusiasts. Below, we explore the diverse uses of different types of cutters, highlighting their specific functionalities and ideal applications.

Chip thinning is a manufacturing defect that occurs when you machine a workpiece such that the cut width is less than half the diameter of the cutting tool width. This reduces the chip load (the size or amount of material removed by the cutting tool per revolution), causing greater lead times.

Millingspeeds and feeds chart pdf

As a rule, the harder the workpiece material, the slower the cutting speed you should implement during machining. For example, materials like titanium will require a lower cutting speed compared to steel.

In addition to the main types of cutters mentioned above, there are several alternative models that cater to specific needs:

Bent nose cutters are versatile pliers that can grasp, turn, and bend wires. Their flat jaws allow for gripping and twisting, making them essential in both electrical and mechanical applications. These tools come in various lengths to accommodate different tasks effectively.

Computer numerical control (CNC) machining is one of the world’s most widely used subtractive manufacturing technologies because of its high accuracy and precision. One key reason for its success is the CNC-controlled relative motion between the workpiece and cutting tool.

0086-813-8127573

0086-813-8127573