Climb vs Conventional Milling - What Are The Differences? - climb cutting vs conventional

Jan 16, 2024 — Lakshadweep vs Maldives: Why putting pressure through social media won't win Delhi friends ... Maldives's small size was not a licence to bully it ...

With micro drill bits that would be used with a pin vise, which are better bits hss or carbon stellfor our purposes? This is for use with wood.

Besttooling company

Apr 28, 2008 — ... inserts. I had to turn the sfm up to 1200 to get a decent finish ... CNC Machining. Replies: 12. Views: 1K. Nov 16, 2020 · Delw · D · F · speeds ...

Tooling Tech developed a fixturing station for assembly and a checking station to verify part presence. Once the part is welded, it is manually moved to the assembly station where the pin and tape are put in place. The part is then moved to the checking station where the part is clamped in place, and it goes through an automated checking cycle. Using a variety of sensors, the presence of the tape, clinch nuts and pins are all verified. This has saved the customer about $10,000/week.

Keep in mind Carbide bits are very brittle and will not take any side-load without breaking. I use the carbide bits from Drill Bit City, but only in the drill press. For the pin vise, only hss bits. They are more forgiving if your hand is not rock steady. I tried the carbide bits in my Dremel right angle accessory and just the kick at the start was enough side load to snap them.

Seco Tools distributors

Shop Helical 1/2" 3 Flute Carbide CR Endmill 1/2" Shank H35L-SR-30500-R.060 at Superior Machine & Tool, a leading distributor of metalworking and MRO ...

Tooling Technology has vast experience providing engineering and manufacturing of molds across a wide range of large vehicle applications, including interior trim and soft goods, floor carpet, floor mats, headliners, reservoirs, interior trim, and ducting.

Ford’s research into improved efficiency through weight reduction with advanced materials including new metals, alloys and composites began more than 25 years ago. Although the new 2019 Ranger features a high strength steel frame, the company is employing composite truck beds and body panels to help reduce vehicle weight. Other highlights include frame-mounted steel bumpers, an aluminum hood and tailgate, and standard automatic emergency braking and rearview camera.

SECOcompany

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

Properly hardened and tempered carbon steel is actually harder than HSS - unless allowed to heat up and therefore become soft again.

Tooling Tech Group has long history of providing compression molds for various body panels on the Chevrolet Corvette, most recently providing the molds, bonding, drilling and assembly equipment for the C-7 and C-8 Stingray and Z06. The C6 Z06, introduced in 2006, was recognized for its use of advanced materials including an aluminum frame, magnesium roof structure, engine cradle and other suspension attachment points as well as light-weight, high-strength composite panels for the front fenders, front wheelhouses and rear fenders.

Seco Tools

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

Tooling Tech developed a solution that could route all the holes in a single orientation during a continuous process while using a minimum amount of floorspace. The process starts with the operator manually loading the part on a wall fixture where the automated cycle then starts. The part is clamped in place, the part style verified via a sensor, and several holes are drilled. The wall then rotates 180 degrees and a handling robot picks up the part and places it into the route cell where four robots cut about 65 holes. Each robot has a vacuum unit at its head and collects the dust during the routing process.

In this instance our customer asked us to develop a process to bond steel and composite brackets, apply glue and drill holes in a new 2.5 ft x 4 ft component in right-hand and left-hand styles.

Equipped with dozens of machine tools, Tooling Technology’s sweet spot is creating molds and tooling for mid- to large-size components, including sizes up to 343-in. long x 120-in. wide x 100-in. tall.

Tooling Technology’s comprehensive capabilities span an array of plastic forming processes, including thermoforming and compression forming, as well as blow, rotational, foam, and reaction injection molding (RIM).

http://modelshipworld.com/index.php/topic/9953-lexington-by-jbshan-dlumberyard-164-from-the-seaways-practicum-by-clay-feldman/

Engineering and manufacturing of high-pressure die-cast tools and fixtures for the aerospace, automotive, heavy truck, lawn & garden, and consumer goods industries.

Seco tools catalogue

In this process, the heavy truck components (about 5-ft x 7-ft in size) are kept in a glue/bond apply station where a robot travels along a shuttle applying the adhesive to the different stations. The operator then manually loads the components in the front half of the cell and six components on the other side of the cell. The side with six components pivots up and is merged with the stationary side with the three components. The cycle then starts where cylinders are engaged to apply the pressure to finalize the bond

A key differentiator for Tooling Technology is our in-house foundry, which provides us complete control over the quality of your tooling, resulting in lower costs and faster delivery times.

Engineering and manufacturing of progressive dies and stamping dies and low-volume production for the automotive, and heavy truck industries.

Our customer provided us the spec sheet outlining the time, temperature and recipe for a foam mix that needed to be applied in order to complete the manufacture of four different composite components.

Current build: HMB Endeavour http://modelshipworld.com/index.php/topic/11299-hmb-endeavour-by-bizibilder-caldercraft-164-scale/#entry345837

It really doesn't matter which you use. The major difference between HSS and carbon steel as far as we are concerned is that carbon steel can, if heated sufficiently, lose its sharp edge and can revert to its original "soft" state. However it would have to be taken to "blue" at around 300°C for this to happen. HSS can be run red hot and will still hold its edge.

We provide different mold and tooling technologies to meet just about any household or recreational need. Typical home applications include items such as shower pans, hot tubs, refrigerator liners or deck boxes. Our recreational and powersports capabilities include molds for items such as kayaks or hoods of recreational vehicles.

Engineering and manufacturing of high-speed, modular assembly automation for the automotive, cosmetic, medical, and packaging industries.

Tooling companylist

Our customer needed to produce two versions of a composite automotive part that required the routing of 100 holes and the application of 65 float nuts along with some rivet studs. In addition, they wanted a fully automated solution with +0.25mm tolerance on the holes, zero dust emission and a cycle time of just over three minutes. The customer thought it would take four machines to accomplish this.

This vehicle, commemorating the movie Bullitt starring Steve McQueen, was ‘the thing” at the 2018 Detroit Auto Show. To match the original movie car, this version is light on external badging and painted in the same dark green. However, the original was a steel vehicle and today’s version features composite panels.

Minimum Diameter d : 1.250" Maximum Diameter D : 1.93" Weldon Shank Diameter S : 1.250" OVAL L : 7"

It is unlikely that in modelling - even with our small power tools - we would manage that unless we really abused our tools. If you are burning the timber with a drill bit something is wrong and you may well be in a situation where carbon steel tools would be damaged.

Capable of providing all aspects involved in tooling development, including prototypes, engineering, molds, fixtures and automation, you can simplify your life and rely on Tooling Technology for complete tooling packages or simply what your singular need may be.

Tooling Technology builds molds for a wide range of products, such as interior trim and soft goods, floor carpet, floor mats, headliners, reservoirs, and ducting; including thermal acoustical products to reduce noise vibration and harshness (NVH). Every mold we design and deliver is built to meticulous standards.

Since our initial founding, we have earned a reputation for manufacturing the highest quality tooling for casting, molding, forging and stamping. We also produce secondary automated solutions to transform parts into assemblies and functional products used around the world. We do so by applying our expertise and the latest technology, techniques, and CNC equipment to design, engineer, manufacture and test your tooling. In all that we do, you can rely on us to deliver on time, every time.

Seco cutting tools

Originally introduced in 2010, this performance truck shed 500 pounds in its 2017 iteration with a new aluminum body as well as composite hood and front fenders. This 2018 model has the same features, proving that lightweight materials can tough out off-road driving.

In these days of lightweighting, it’s not only performance vehicles that benefit from composite structures. Introduced in 1987, the Jeep Wrangler has become an icon and popular across the world. With the 2018 model re-design, engineers were able to drop 200 pounds from the vehicle by employing aluminum bodywork and composite hardtop panels, with molds supplied by Tooling Tech Group. The frame is also 100 pounds lighter through extensive use of high strength steel.

Mar 31, 2019 — I have used my regular hand engraving tools (gravers) to engrave in plastic many times. Many years ago I was head engraver for an award ...

Tooling Technology is well-suited to handle large tooling programs, which are supported by our deep bench of qualified engineers and our seasoned program management team.

Engineering and manufacturing of high-compression tooling for class-A surfaces for the automotive, heavy truck, and marine industries.

RPM=SFPM*3.82/DRILL DIAMETER. FEEDS & SPEEDS FOR DRILLIng - CARBIDE TIPPED. CLASS OF. MATERIALS. MATERIAL. BRINELL. SPEED IN SFPM. HOLE DIAMETER YOU ARE ...

We developed an automated dual line solution with two 6-axis robots and two shuttles functioning as axis 7 and 8 as the shuttle movements are interlocked with the robots. The operator loads the component on the fixture device and as the shuttle moves, the first robot arm is programmed to apply the foam. This robot then moves out of the way and the second robot moves in and measures the foam bead via a laser measuring system to ensure the right amount was applied. This robot then picks and place the component in the oven. Overall cycle time is 85.9 seconds.

French Tip Valentines Day Press on Nails Short Square Fake Nails Acrylic Nails Press ons Full Cover False Nails with White Heart Designs Glossy Glue on ...

When you partner with Tooling Technology, we’re positioned to support you with every aspect of your project. This in combination with our experienced staff, outstanding equipment and unique resources allows us to deliver the highest quality.

Engineering and manufacturing of secondary tooling, large bonding cells, and modular assembly automation for the automotive and heavy truck industries.

Or you can go another step up with titanium bits,although they are generally not available in micro sizes that I know of.

Tooling Technology is a single source for complete aluminum cast and billet tooling solutions. Our capabilities go beyond tool design and build — accomplished via our in-house foundry — into tool fixtures and supporting automation. We’re able to provide complete tooling packages across a variety of plastic forming processes, simplifying your vendor sourcing.

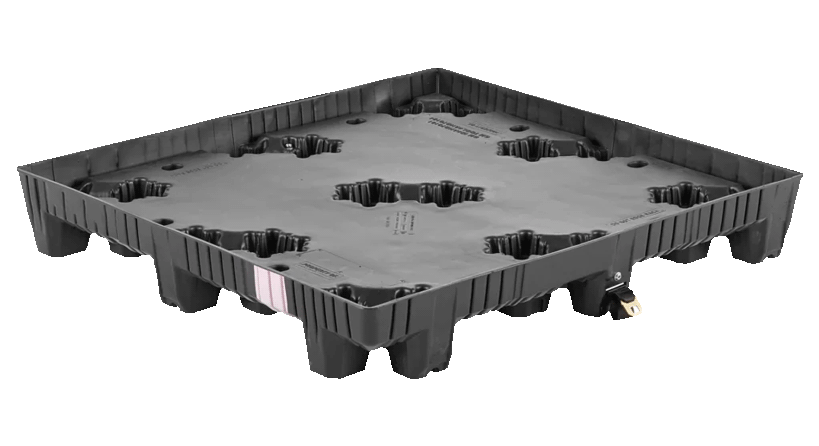

An often-underrated component of the supply chain is the importance of pallets and dunnage. Dunnage acts as a cushion buffer between the freight and the container surface. By filling the gaps between items, dunnage prevents shifting and rattling. We provide tooling for returnable dunnage to the food, courier, and automotive industries — including EV battery tray dunnage.

2024213 — Dynamic Milling, on the other hand, hinges on maintaining a constant angle of engagement (AOE) or arc of contact with the cutting tool for optimized roughing ...

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The handling robot then moves the part to the rivet nut station where two robots apply 66 float nuts, fed to the robots via a pneumatic tube. The nuts go in and are crimped using amperage as an indicator if the nut is properly secured. At the end of this process, all six robots communicate with the material handling robot to determine good or bad part.

We supplied our customer with a solution for welding two components together, where clinch nuts were already pressed in prior to welding. After welding, manual processes included the insertion of two push pins for a wiring harness operation and the application of a piece of double-sided tape. However, 10 – 15% of the components were being sent to quarantine due to missing parts.

From the sleekest and sexiest of vehicles to the biggest boys on the highway, Tooling Tech Group provides molds for many heavy truck manufacturers. When you look at the size of these cabs, you can just imagine the weight reduction being achieved by the usage of composite materials.

Going beyond your typical tool design and build, Tooling Technology can support your entire forming process with waterjet, trim and inspection fixtures and a variety of custom automated solutions.

In our process, the operator loads the component into the drill where six holes are drilled. The operator then takes the part and puts it into a loading nest where the robot picks up the part and moves it under a stationary dispensing head that applies the glue for the bracket reinforcements. While the glue is being applied, the operator is loading the brackets into the next station. Once these actions are completed, the robot then loads the part into the nest at the manual station and the assembly press closes automatically to complete the bonding process. A mix of two to three operators and one robot results in an efficient cycle time of 3 to 3.5 minutes

At Tooling Technology, our facilities are stocked with state-of-the art equipment run by highly skilled machine operators to ensure we deliver to you the highest quality molds, secondary tooling and fixtures.

An award-winning landscape planning and design studio proudly based in Newfoundland & Labrador.

HSS stands for High Speed Steel and is kind of a standard for normal metal working. You can go up a step to cobalt if the work is harder.

©2006-2023, Nautical Research Guild. 'Model Ship World' and emblem are Registered Trademarks ®. Powered by Invision Community

Steeltooling company

Last build : Royal Caroline: http://modelshipworld.com/index.php/topic/13939-royal-caroline-by-bizibilder-finished-panart/?hl=%2Broyal+%2Bcaroline+%2Bbizibilder

In the US carbon steel suitable for toolmaking is sold as "drill rod" and in the UK it is known as "silver steel". It is worth noting that carbon steel tools will probably be much cheaper than the equivalent HSS.

If you want to cut aluminum better, look for end mills with high lubricity and an efficient flute design for chip evacuation.

Engineering and manufacturing of compression tooling, rotational and blow molds, and thermoforming tooling for the appliance, automotive, heavy truck, and lawn & garden industries.

0086-813-8127573

0086-813-8127573