CNC Projects - cnc plywood projects

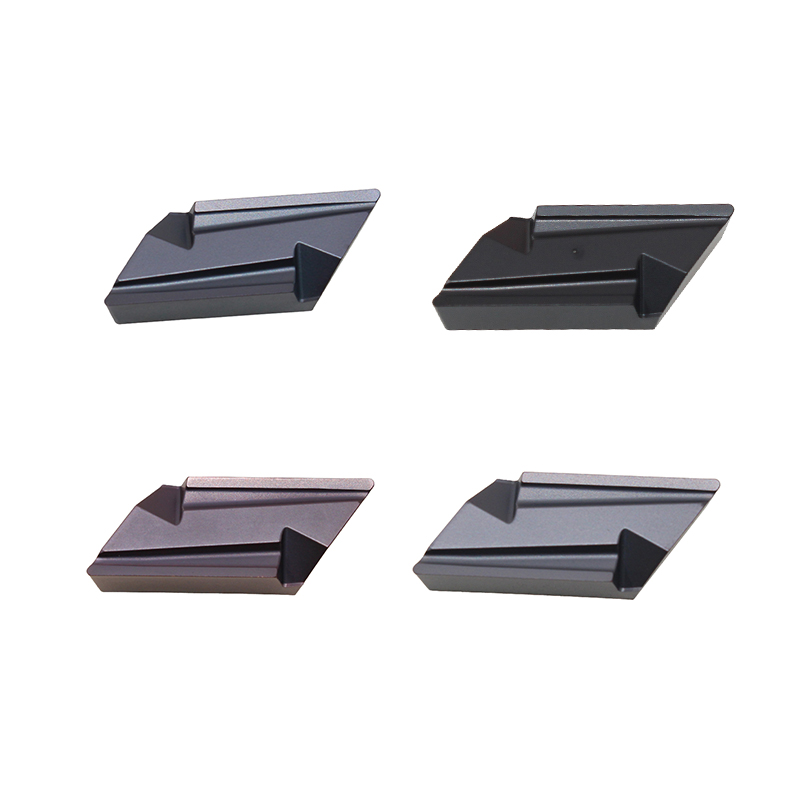

Endmillcuttertypes

Usedend milling cutter has teeth

EndMillCutter

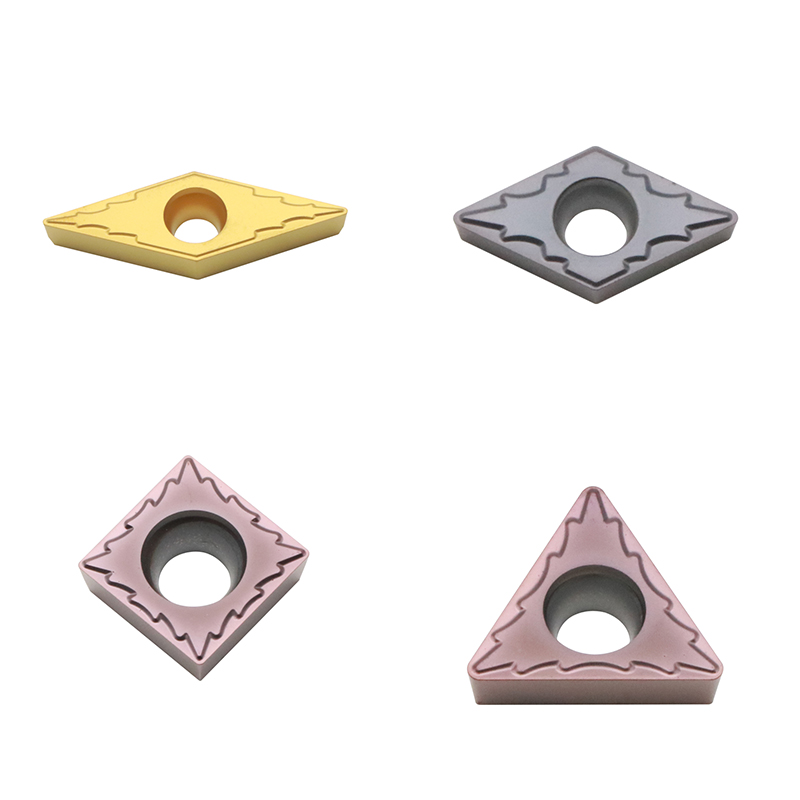

Customer-specific custom tools made of solid carbide for highest requirements.Realisation of complex geometries and contours for almost all applicationsHigh-performance coatings for every materialCombination of several standard tools into one high-performance custom tool

Endmillcutterspecification

Ideal for producing the best surface finishes. Fine machining with low stock removal. Low material removal rate (ae ≤ 0.1xD) Diameter range from 4 to 32 mm Large number of teeth Optimal distribution of the cutting forces Special design for hardened steels of 50-65 HRC

Contour and copy milling with high shape accuracy. Low material removal rate (ap ~ 0.1xD, ae ~ 0.1xD) Diameter range from 1 to 25 mm Small diameter (from 1 mm) especially for milling tool steel and hardened steels from 50 to 65 HRC Highest precision for tool and mould building Close radius tolerances with full radius and toric end milling cutters

To achieve the highest material removal. Ideal for pre-machining with high stock removal. High material removal rate (ae ~ 0.6xD) Diameter range from 4 to 25 mm New knurled profile for optimal force distribution on the cutting edge Profile undercut roughing teeth Unequal spacing for low vibration running

End milling cutter has teethmeaning

Cost-effective chamfering and deburring of pre-machined parts. Diameter range from 3 to 20 mm Drill milling cutter for combination machining in one machining step, in particular for sheet metal and thin-walled parts Designs with replaceable head system for highest flexibility and cost-effectiveness

Milling cutters for general applications. Excellently suited to groove milling.Contact width ae up to 1xDDiameter range from 1 to 25 mm (solid carbide)PCD variants up to diameter 63 mmOptimal chip transportLarge selection of lengths and geometries for all applicationsHigh-performance substrate and modern coatings for excellent tool lives

Especially for milling with high feeds and extreme cutting speeds. Low cutting depth (ap = 0.05xD) Diameter range from 8 to 25 mm High feeds up to 1.35 mm per tooth at diameter 20 mm. Inclined entry and pocket milling also with long projection lengths Internal coolant supply for optimum chip removal

Maximum material removal rate with high surface finish at the same time. Pre-machining and fine machining using one tool. Cutting depths up to 3xD Diameter range from 4 to 25 mm Extra long cutting tool Optimised unequal spacing and finely balanced cutting tool to protect the machine spindle and longer tool lives Optimal chip transport Usage with modern CAM system

0086-813-8127573

0086-813-8127573