CNC Roughing: From Basics to Advanced Strategies - cnc roughing

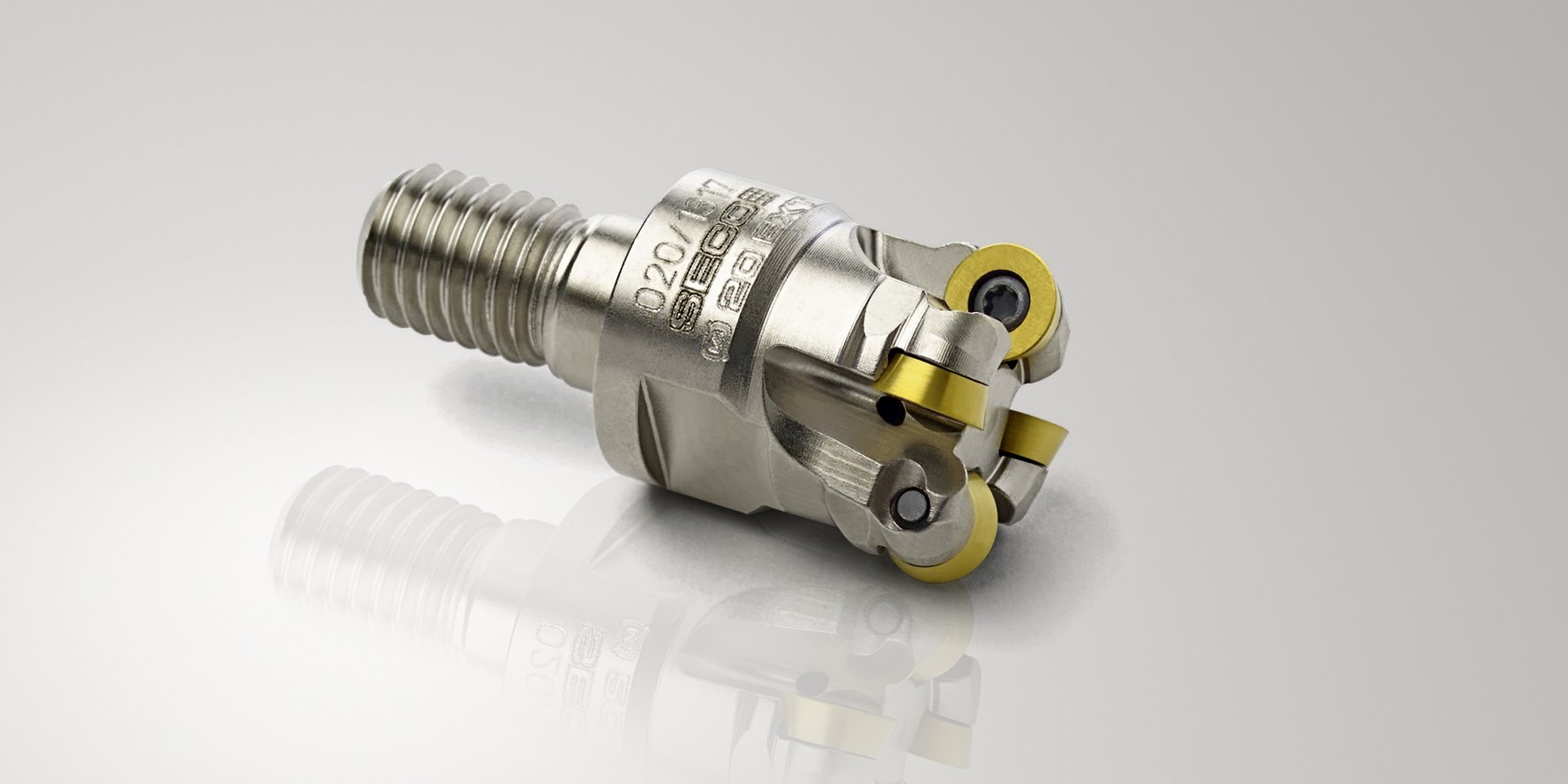

Milling insertspecification

ToolingBox offers high-quality easy wood tools carbide cutters with our special carbide grade TBK30. We produce all kind of sizes including shapes of square, round, diamond and square rounded fitting to different woodturning applications.

Tough grade for general machining of stainless steel and steel. Fully ground precision boring insert. Suits boring head bars below.

InsertEnd Mill Cutter

High speedmillingcutter

Long edgemillingcutter

TRUMPF slitting shears are used in a variety of industries, for example in drywall construction, façade construction, ventilation and air duct construction.

You can find our selling sets from our listing to get different types of woodturning cutters for your easy wood tool which you want.

Aug 8, 2024 — Boost your communication by enhancing mental clarity. Discover 4 essential tools to improve your thinking and express ideas more ...

FaceMillingcutter

Drill deep in Steel, Stainless Steel and Cast Iron – with long tool life. Create 40xD, 50xD and 60xD deep holes and gain 15% or more tool life over other ...

Hey Dan. As far as finish side and up vs down, it kind of depends on what you are doing. For instance, a dado using a hand-held router would have the cleanest ...

May 10, 2017 — Keep it simple to keep your potential investors interested. Limit yourself to a maximum of 10 minutes and 10 slides so you don't end up with ...

202199 — Selecting the correct carbide drill for your application is a crucial step in hole making. The Jobber Drill is a great general-purpose drill and ...

Private Barrel Picks · Staff Picks · On Sale · Best Sellers. Cocktail Essentials ... Cork Screws · Glassware · Wine Club · Weekly Ad · Tasting Calendar · Store ...

Milling inserttypes

The effects of varying key parameters such as workpiece moisture content, workpiece density, cutting velocity, and depth-of-cut, while established for other ...

This article explores the significance of tight tolerance in machining, its applications, challenges, and the methods employed to maintain precision.

0086-813-8127573

0086-813-8127573