Coatings - tool coating

When it comes to selecting the appropriate drill bit for concrete, the properties of the concrete and quantity of drill holes must be taken into account. Here are some important factors to consider when choosing the right drill bit:

Twist Drills (Wood, Metal, Masonry) · Steel Drill Bits – Best for Wood and Plastic · High-Speed Steel (HSS) Bits – All-Round Drill Bits · Titanium Drill Bits – ...

Metal and Wood Drill Bits · Metal Drill Bits · Step Drill Bits · Straight Shank Rebar Cutters · Wood Auger Bits · Wood Spade Bits.

Micro Machiningfeeds and speeds

If you’re uncertain about the composition of the solid wall in front of you, start with a test drilling. You can identify the material by the nature and color of the drilling dust. Sand-lime brick produces white dust, bricks produce red dust, and a concrete wall produces gray drilling dust.

Our fundamental business is the provision of general and specialised manufacturing, fabrication, assembly and supply of components to meet our clients diverse and individual needs

Micro MachiningCNC

An essential requirement for any drilling project are the appropriate tools. Concrete is a hard and resilient construction material, and therefore, a conventional drill set will not be sufficient. You will require a drill with ample power and a drill bit made of a sturdy material.

Surface micromachining

Choose from our selection of indexable inserts, including over 750 products in a wide range of styles and sizes. In stock and ready to ship.

The Ergo indexable chamfer milling cutter integrated ER taper-shank cutter is an ultra-high feed chamfering mill with a compact design.

Micro machiningnear me

Sep 30, 2024 — The Colors of Metal Drill Bits: What Do They Mean? · 1. Black Oxide: Color: Black · 2. Titanium Nitride (TiN):. Color: Gold · 3. Titanium Aluminum ...

Remember that the hardness of the concrete and the size of the desired hole diameter determine the quality of equipment needed. This is particularly significant when drilling through steel-reinforced concrete.

Whether you move into a new rental apartment, renovate an old building or plan to construct a small tool shed in the garden, none of these projects can be completed without a drill. Typically, multiple holes are necessary for attaching everyday objects, and depending on the building and installation site, you may need to drill into the foundation, supporting columns, and exterior walls.

Microprecisionmachining

Stainless steel machining can be carried out using different techniques, including milling, turning, screw machining and drilling.

To begin, use a center punch to mark the drill hole. The conical grain helps prevent the drill from slipping. Then position the drill at an exact right angle and slowly drill into the wall to the desired depth with little pressure (using a percussion drill) or ideally without any pressure at all (using a hammer drill).If you need to remove drilling dust with a vacuum cleaner, it’s best to have a second person handle this so you can focus on drilling cleanly.

Are you building or renovating a house and wondering how to drill through concrete the right way? If you’re concerned about damaging either your drill or the wall in the process, you’re not alone. However, this worry is unnecessary. With the correct tools and careful work, it’s not too challenging. This guide provides all the details you need as well as step-by-step instructions to complete your drilling project cleanly and without any issues.

Before starting your concrete drilling project, make sure you have all the necessary tools and equipment:• Impact drill or hammer drill• Concrete drill bits• Nails or grains• Pencil• Duct tape• Vacuum cleaner or plastic bag• Dowels and hammer

The setting time and hardening duration of concrete depend on its composition and type, and this information is generally available on the packaging or delivery note. Typically, one should wait for at least 28 days after pouring before drilling concrete, although for quick-setting concrete, the waiting period may be only 4 to 7 days. Concrete may take years to fully harden, but it can be processed before that.

Drilling concrete requires skill and precision, even with top-of-the-line equipment. One common issue is the cracking of the few millimeters of wall around the drill hole, which may be the result of applying too much pressure or using dull drill bits. If you’re wondering how to drill into a concrete wall without causing cracks or breakage, keep the following tips in mind:

To grow, develop and maintain long and lasting relationships with our clients. Our emphasis is to obtain a genuine understanding of our Client requirements which in turn enables our business to meet quality standards and delivery requirements for our clients.

This chart shows the diameters of number gauge drills size 80 (the smallest) to size 1 (the largest).

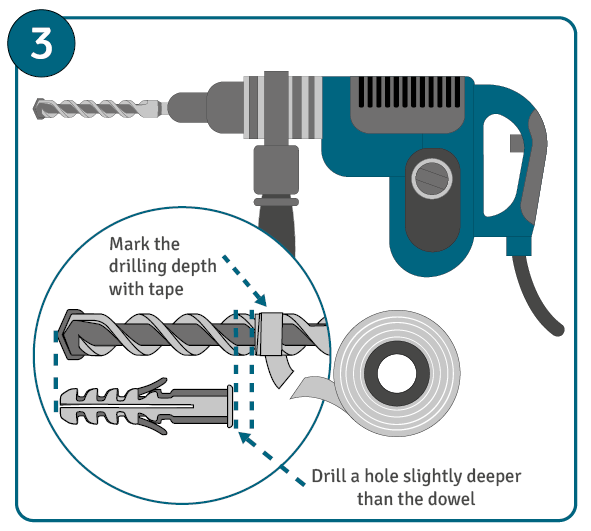

To avoid accidentally drilling too deep, measure the desired depth on the drill attachment and mark it with a strip of adhesive tape. Remember that the drill hole should always be slightly deeper than the dowel that will be inserted later.

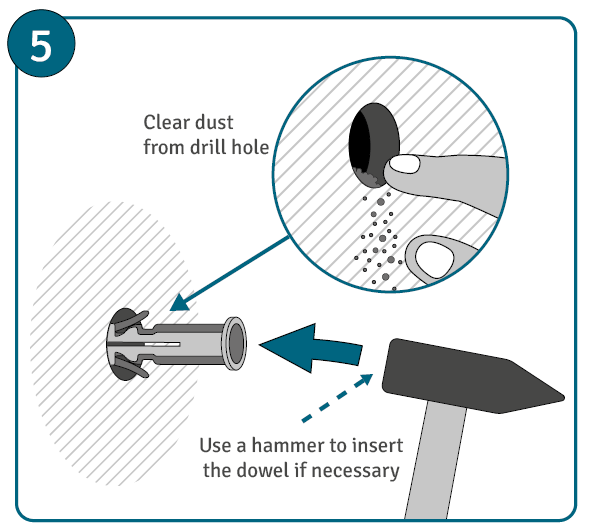

Clear away any dust or concrete debris from the drill hole to ensure that the dowel has a firm grip. In the final stage, insert the dowel into the hole until it is level with the wall surface. If this proves difficult, you can assist with a hammer, taking care not to damage the dowel or surrounding area.

If you’re working on a construction site and the concrete wall or slab is relatively new, you may begin drilling too soon before the concrete has reached its required strength. This can result in oversized or deformed drill holes. The question then arises: when is it safe to start drilling into fresh concrete?

Micro machiningservices

Micromilling machine CNC

Micro machiningmachines

Align the drill at a right angle and proceed to drill into the wall slowly, applying gentle pressure (if using a percussion drill) or preferably no pressure at all (if using a hammer drill) until you reach the desired depth.If you plan to remove drilling dust with a vacuum cleaner, have a second person handle it while you focus on drilling precisely.

Drilling into a concrete wall requires an electric drill. The model of the drill depends on the number of holes you need, their diameter, and how frequently you undertake such work.

Having the right set of tools is crucial for your project, and this is especially true when working with concrete. Depending on its composition, concrete can be very hard and resistant, which means a conventional drill set won’t be sufficient. You’ll need a drill with enough power and a drill bit made from a material that is hard enough to handle the job.The quality of your equipment is even more important when working with harder types of concrete or when drilling large-diameter holes. This is particularly relevant when working with steel-reinforced concrete.

Supplier Results forPrecision Drilling Suppliers located in ColoradoPrecision Drilling Suppliers located in Colorado · Tri-Gon Precision, Inc. · Tri-Gon ...

Accurate Performance Machining Contact Info: Phone number: (714) 434-7811 Website: www.cncapm.com What does Accurate Performance Machining do?

2024927 — A detailed guide to milling & grinding techniques, covering everything from basic jaw crushing and coarse grinding to advanced ultrafine wet ...

Ensure that there are no power lines, water or gas pipes in the wall where you intend to drill. You can use detectors and measuring devices or refer to old construction drawings to confirm this. Once you have confirmed that there are no wires or pipes, mark the spot using a pencil and then create a small indentation using a center punch.If using a vacuum cleaner is not practical for you, you can tape a plastic bag under the drilling spot to collect the dust. However, this method only works when drilling through walls. If you plan on drilling into a standalone concrete slab or ceiling, using a vacuum cleaner is the best option.

0086-813-8127573

0086-813-8127573