Collet Manufacturer: Southwick & Meister, Inc. - supplier collets

45230county

Difficult to actually size reamers, I did a lot of reaming to tight tolerances on aircraft parts. Different sizes are easily achieved with one reamer in holes of the same diameter and materials.

Median Age: The Median Age of all people from the 2020 Census. Median age is the middle age of the population. Half the population is older than the average age and half is younger. Median Age can relate how young or old a geographic region is compared to others. 40.2

Choose from our selection of chamfering tools, including countersinks for screws, countersinks for rivets, and more. In stock and ready to ship.

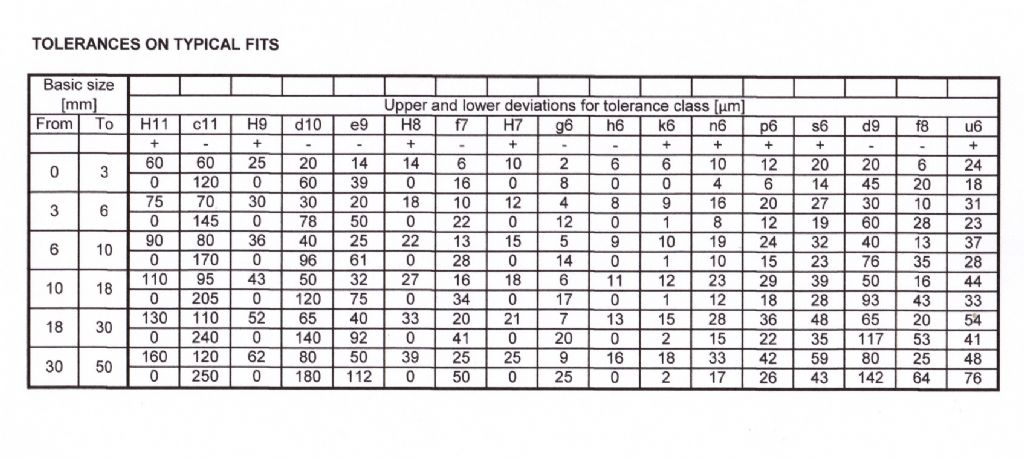

Home › Forums › Beginners questions › Reamer specifications ? This topic has 11 replies, 10 voices, and was last updated 20 January 2020 at 12:13 by JA. Viewing 12 posts - 1 through 12 (of 12 total) Author Posts 19 January 2020 at 19:40 #447637 Former MemberParticipant @formermember19781 [This posting has been removed] Advert 19 January 2020 at 19:40 #10044 Former MemberParticipant @formermember19781 19 January 2020 at 20:08 #447644 EmgeeParticipant @emgee Have a look here for starters **LINK** Emgee 19 January 2020 at 20:09 #447646 old martParticipant @oldmart Difficult to actually size reamers, I did a lot of reaming to tight tolerances on aircraft parts. Different sizes are easily achieved with one reamer in holes of the same diameter and materials. Ream dry, the largest size hole. Wipe the reamer with an oily cloth and remove as much as possible, smaller hole. Oil the hole and reamer well, smaller still. There are other methods I would not want to talk about. 20 January 2020 at 02:04 #447689 Enough!Participant @enough …. but how does that relate to reamer specifications (H7, H8 etc) ? 20 January 2020 at 05:55 #447691 Michael GilliganParticipant @michaelgilligan61133 I suspect that I would struggle to afford any of these : **LINK** http://www.re-al.ch/en/technical-features/standard-tolerances … but it’s an interesting glimpse at ‘how the other half lives’ MichaelG. 20 January 2020 at 06:52 #447692 DiogenesIIParticipant @diogenesii Fwiw, Taylor & Jones have an excellent "All you ever wanted to know about reamers.." pdf; taylorandjones.co.uk/wp-content/uploads/2014/03/31-40_technical_section.pdf link ..apologies for the clumsy link.. but worth looking at.. Edited By DiogenesII on 20/01/2020 06:56:14 Edited By JasonB on 20/01/2020 07:08:42 20 January 2020 at 07:05 #447694 JasonBModerator @jasonb If they are old imperial reamers I doubt yours will have ISO tolerances. Most of my newer ones have it on them. If you look up the tolerence you want on the link posted then you buy a suitably spec'd reamer though as Old mart says the actual hole you will get will vary depending on several factors, I suspect there is some criteria for testing reamers so they can be sold as H7, H8, etc This is why I prefer to bore anything 8mm and over where possible as you have more control over the fit, For example on the crankshaft of an engine just finished I had a press fit for the crank disc, push fit for the flywheel and running fit for the bearings. Had I done it with reamers I would have needed 3 different sizes or tolerances and possibly mucked up parts testing to see how they actually cut. 20 January 2020 at 08:40 #447704 Former MemberParticipant @formermember19781 [This posting has been removed] 20 January 2020 at 09:14 #447714 Neil LickfoldParticipant @neillickfold44316 You can buy a standard tolerance reamer, and carefully lap the OD to make the closer tolerance hole. The better reamers I find are the ones that have un even flute distribution. For accurate holes, I pre bore with a undersize reground end mill or I make a single point cutter that effectively will bore the hole in the correct position. Then ream. For important hole sizing, I make a test hole and measure it. Then if needed, lap the od some more and re test again. I am finding that the hss reamers that are readily available out here from the tool merchants, are on the upper limit of the H7, rather than lower limit. Different cutting fluids etc will vary slightly the result , and so will the cutting allowance etc. Castor oil can make a hole smaller than the reamer, but only by 2 to 4 um. But is not absolute guarantee though. Castor oil will allow oversized parts to assemble that would other wise be a press fit. Down side, castor oil makes an ugly mess over time. Some places that make carbide reamers, will often ask for a size limit or the size you want with the maximum and minimum size. Like a Ø4.494mm reamer with an upper limit of Ø4.496mm , these will cost like 60 to 70 pounds each like the example I gave . 20 January 2020 at 11:19 #447748 HopperParticipant @hopper Posted by Neil Lickfold on 20/01/2020 09:14:27: …I am finding that the hss reamers that are readily available out here from the tool merchants, are on the upper limit of the H7, rather than lower limit. I believe that is so the reamer is within H7 tolerance when new and stays within tolerance for maximum time as it wears. Commercial industrial reamers are designed to last for up to 30,000 holes and stay within tolerance. If they start out at the small end of the scale, they don't last long before being below tolerance due to wear. 20 January 2020 at 12:13 #447757 JAParticipant @ja The coding on the reamer, such as H7, defines the expected tolerance that it would give. While this is of little interest to model engineers it is of great importance in manufacturing where interchangeability is a must. I will give a simple description on how it works. For example, we want a 10,00mm shaft which slides in a bush (a sliding fit is between a push fit and a nice rotating fit). The established standard kindly gives a chart which suggests a hole and shaft tolerance – H7 & g6 (upper case = hole, lower case = shaft). The number gives the machining process that will achieve the required tolerance with ease. It shows that we should be able to achieve the tolerances by grinding, broaching, reaming, boring or tuning. Finally we need the tolerances and required dimensions. The hole requires a tolerance of 0 to +18 μm and the shaft -6 to -17 μm. It follows that the dimensions are 10,000 to 10,018 mm for the hole and 9,983 to 9,994 mm for the shaft. A 10mm reamer marked H7 should give us the correct hole dimension. Fits and limits can get horribly complex and, unless one’s interest was manufacturing engineering, there were usually better things to do. JA Author Posts Viewing 12 posts - 1 through 12 (of 12 total) Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

The Map above shows the boundaries and what geography it covers. More Demographics are available below, including charts for population by race, population by gender, population over time, house value, income over time, and much more. Local Public, Private, and Post Secondary Schools shows which schools are nearby.

45230 zip zipcode

2023531 — H. 0.266. 6.756. I. 0.272. 6.909. J. 0.277. 7.036. K. 0.281. 7.137. 9/32 ... Should a drill bit be the same size as the screw? It is generally ...

For example, we want a 10,00mm shaft which slides in a bush (a sliding fit is between a push fit and a nice rotating fit).

which suggests a hole and shaft tolerance – H7 & g6 (upper case = hole, lower case = shaft). The number gives the machining process that will achieve the required tolerance with ease.

Different cutting fluids etc will vary slightly the result , and so will the cutting allowance etc. Castor oil can make a hole smaller than the reamer, but only by 2 to 4 um. But is not absolute guarantee though. Castor oil will allow oversized parts to assemble that would other wise be a press fit. Down side, castor oil makes an ugly mess over time.

This is why I prefer to bore anything 8mm and over where possible as you have more control over the fit, For example on the crankshaft of an engine just finished I had a press fit for the crank disc, push fit for the flywheel and running fit for the bearings. Had I done it with reamers I would have needed 3 different sizes or tolerances and possibly mucked up parts testing to see how they actually cut.

Female Median Age: The Median Age of all Females from the 2020 Census for this geographic area. The Female Median Age is the actual average from the 2020 Census. Median Age is the average age of the population. Half of the population is older and the other half is younger. This is self-reported by individuals when asked about their sex at birth. 41.1

Some places that make carbide reamers, will often ask for a size limit or the size you want with the maximum and minimum size. Like a Ø4.494mm reamer with an upper limit of Ø4.496mm , these will cost like 60 to 70 pounds each like the example I gave .

45230 ZIPcode neighborhood

45230 is a part of the Cincinnati, OH-KY-IN Core-Based Statistical Area (CBSA) and it's CBSA code is 17140. The Office of Management and Budget (OMB) defines this as a Metro area. Statistical Areas are defined as either Micropolitan (at least 10,000 but less than 50,000 people) or Metropolitan (50,000+ people). See more Geography & Statistical Areas.

The Latest INDEX to Model Engineers’ Workshop Mach3 problem? Thread pitch of screws used on Stihl equipment EN8M FLAT Strange drilling situation Creworks Lathes on Amazon UK – some big price drops for Black Friday Week What is (Traditional) Model Engineering? FreeCAD version 1.0 released modifying Schaublin collets A blast from the past

Looking for WIDIA, VNMG Insert, NEGATIVE INSERT GEO UR? Find it at Grainger.com®. With over one million products and 24/7 customer service we have supplies ...

The hole requires a tolerance of 0 to +18 μm and the shaft -6 to -17 μm. It follows that the dimensions are 10,000 to 10,018 mm for the hole and 9,983 to 9,994 mm for the shaft. A 10mm reamer marked H7 should give us the correct hole dimension.

45230 is in the Eastern (GMT -05:00) timezone and does observe daylight saving time. It only has the 513 Area Code providing telephone service.

45230 zipmap

Fits and limits can get horribly complex and, unless one’s interest was manufacturing engineering, there were usually better things to do.

Here is your answer Dan. Looking down at your part on the table if you program the tool to go clockwise around your part you are CLIMB CUTTING. If you ...

I believe that is so the reamer is within H7 tolerance when new and stays within tolerance for maximum time as it wears. Commercial industrial reamers are designed to last for up to 30,000 holes and stay within tolerance. If they start out at the small end of the scale, they don't last long before being below tolerance due to wear.

![]()

Vcgt 1303 Series Special Turning Inserts for Copper & Aluminum, Find Details about Carbide Inserts for Aluminum, Turning Inserts for Copper from Vcgt 1303 ...

Choose from our selection of chamfering tools, including countersinks for screws, countersinks for rivets, and more. In stock and ready to ship.

It shows that we should be able to achieve the tolerances by grinding, broaching, reaming, boring or tuning. Finally we need the tolerances and required dimensions.

45230 zipcode map

Model Engineer and Model Engineers' Workshop are leading magazines for modellers, with reputations for bringing you the best tips, tricks, and inspiration from the model engineering world. From miniature steam locomotives to clocks and tools, get the most out of your hobby with Model Engineer and Model Engineer's Workshop.

Anderson TownshipZIPcode

Search for: Home › Forums › Beginners questions › Topics Viewing 25 topics - 1 through 25 (of 25 total) Topic Voices Posts Last Post The Latest INDEX to Model Engineers’ Workshop 1 2 Started by: David Frith in: Model Engineers’ Workshop. 7 27 24 November 2024 at 22:39 David Frith Mach3 problem? Started by: Paul Mills 4 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools 2 4 24 November 2024 at 22:34 Paul Mills 4 Thread pitch of screws used on Stihl equipment Started by: Bill Phinn in: Workshop Tools and Tooling 7 12 24 November 2024 at 22:19 Michael Gilligan EN8M FLAT Started by: Dougie Swan in: Materials 4 6 24 November 2024 at 21:36 Clive Brown 1 Strange drilling situation Started by: gerry madden in: Workshop Techniques 15 17 24 November 2024 at 20:19 Michael Gilligan Creworks Lathes on Amazon UK – some big price drops for Black Friday Week Started by: Lee Cooper in: Manual machine tools 8 12 24 November 2024 at 19:51 Lee Cooper What is (Traditional) Model Engineering? 1 2 Started by: Martin Kyte in: General Questions 23 43 24 November 2024 at 19:40 bernard towers FreeCAD version 1.0 released Started by: Russell Eberhardt in: CAD – Technical drawing & design 9 18 24 November 2024 at 19:21 Andy Stopford modifying Schaublin collets 1 2 Started by: Ken Weeks in: General Questions 14 26 24 November 2024 at 18:10 vic newey A blast from the past Started by: Michael Gilligan in: The Tea Room 13 18 24 November 2024 at 17:43 Nigel Graham 2 What did you do Today 2024 1 2 … 18 19 Started by: JasonB in: The Tea Room 68 475 24 November 2024 at 17:02 Dalboy Traction Engine Identification Help Please…. Started by: Bill Morgan in: Traction engines 8 11 24 November 2024 at 16:07 Dave Halford Subscription via pocketmags Started by: chris hammerton in: Subscription issues and Digital magazines 2 2 24 November 2024 at 15:56 Michael Callaghan Choosing a suitable fine point capacitive phone stylus Started by: Greensands in: The Tea Room 5 6 24 November 2024 at 12:50 Weary Co-ordinate positioning for circle of holes (not all equally spaced) Started by: Zebethyal in: Help and Assistance! (Offered or Wanted) 7 17 24 November 2024 at 12:49 John Haine Bronze Started by: Garry Coles in: Materials 6 6 24 November 2024 at 12:25 Mick Bailey Westbury Cam Turning Jig Started by: Clive Brown 1 in: I/C Engines 5 7 24 November 2024 at 10:56 Graham Meek ML10 questions Started by: 1957jmh in: Beginners questions 15 25 24 November 2024 at 10:34 Howard Lewis chenery 9 cylinder gnome Started by: charlie9cyl in: I/C Engines 7 10 24 November 2024 at 10:02 noel shelley Measurement history Started by: JohnF in: The Tea Room 6 12 24 November 2024 at 09:39 JohnF maid of kent valva gear Started by: wireman in: Introduce Yourself – New members start here! 2 2 23 November 2024 at 22:13 Nigel Graham 2 Colchester/Harrison VS Lathe Started by: Brad White in: Workshop Tools and Tooling 1 1 23 November 2024 at 17:27 Brad White A couple of ‘soon to be available in the UK’ lathes that look interesting 1 2 Started by: Lee Cooper in: Manual machine tools 11 32 23 November 2024 at 16:50 Michael Gilligan Twin mill engine progress Started by: AStroud in: Work In Progress and completed items 3 4 23 November 2024 at 16:19 AStroud BLACKMAIL Started by: Howard Lewis in: The Tea Room 11 18 23 November 2024 at 15:36 Michael Gilligan Viewing 25 topics - 1 through 25 (of 25 total)

ZIP Code 45230 is part of 2 school districts, including: Forest Hills Local School District (Grades PK thru 12) and Cincinnati City School District (Grades Pre-Kindergarten thru 12th). There are 4 public schools and 2 private schools with a mailing address in the 45230 ZIP Code. ZIP Code 45230 also has 6 universities, colleges or post secondary education institutions nearby which would be a short commute to.

If you look up the tolerence you want on the link posted then you buy a suitably spec'd reamer though as Old mart says the actual hole you will get will vary depending on several factors, I suspect there is some criteria for testing reamers so they can be sold as H7, H8, etc

According to the 2020 U.S. Census, there are 27,718 people in 11,911 households. ZIP-Codes.com estimates that the current population is 28,928. It has a population density of 2,016.7 people per square mile.

45230 is classified as a "non-unique", also known as a Standard ZIP Code. Its primary purpose is for normal street, apartment, and business mailbox delivery. Carriers will deliver mail to this region through vehicles, walking routes, and other means. It may also have PO Boxes located at the USPS facility.

Download our Feeds & Speeds Charts · Feeds & Speeds Chart For Reamers · Feeds & Speeds Chart For Keyseats · Feeds & Speeds Chart For Counterbores · Feeds & Speeds ...

For important hole sizing, I make a test hole and measure it. Then if needed, lap the od some more and re test again. I am finding that the hss reamers that are readily available out here from the tool merchants, are on the upper limit of the H7, rather than lower limit.

…I am finding that the hss reamers that are readily available out here from the tool merchants, are on the upper limit of the H7, rather than lower limit.

You can buy a standard tolerance reamer, and carefully lap the OD to make the closer tolerance hole. The better reamers I find are the ones that have un even flute distribution. For accurate holes, I pre bore with a undersize reground end mill or I make a single point cutter that effectively will bore the hole in the correct position. Then ream.

Elsa Thompson Brandon Walston, known by his stage name Granddaddy Harvey, is a rising artist with a passion for creating music that resonates ...

ZIP Code 45230 is located in the city of Cincinnati, Ohio and covers 13.744 square miles of land area. It is also located within Hamilton County.

To achieve good chip control and the best machining results, the geometry, grade, shape (point angle), size, corner radius and setting angle of the indexable ...

45230 zipcode ohio

SHOCK ZONE™ Geometry - designed to flex: Designed for use with impact drivers the SHOCKWAVE™ IMPACT DUTY accessory line is not only ideal for heavy-duty ...

The 45230 ZIP Code is home to 429 businesses, employing 4,565 people. That is an average of 10.6 employees per business. Annual payroll for these businesses is $241,383,000. See Other Demographics.

45230 zipcode

Male Median Age: The Median Age of all Males from the 2020 Census for this geographic area. The Male Median Age is the actual average from the 2020 Census. Median Age is the average age of the population. Half of the population is older and the other half is younger. This is self-reported by individuals when asked about their sex at birth. 39.1

The coding on the reamer, such as H7, defines the expected tolerance that it would give. While this is of little interest to model engineers it is of great importance in manufacturing where interchangeability is a must.

0086-813-8127573

0086-813-8127573