Combo Lathe/Milling Machine, 43" L x 19-1/2" W x 38" H - 3 in 1 lathe mill drill

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

WHY BECOME A MILWAUKEE TOOL SUPPLIER? Milwaukee Tool's global success as a leader in our industry is fueled by the strength of our suppliers and partners.

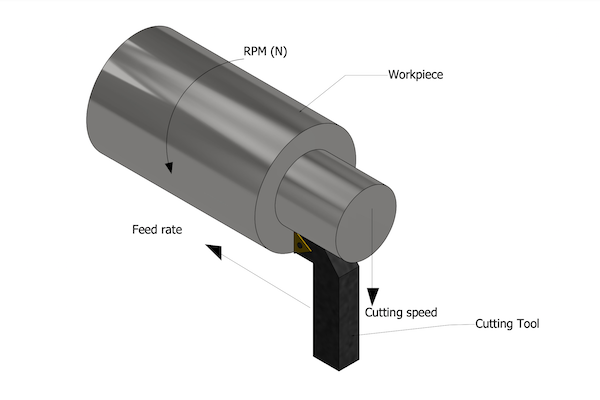

To determine the optimum cutting speed for your machining project, you need to consider the workpiece hardness and the strength of the cutting tool.

Feed rates also affect the tool life and power consumption during machining, but their effects are usually negligible compared to cutting force. Instead, feed rates are more likely to affect the machining time and surface finish of the machined part.

Milling machine feed ratechart

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

Back; Other Hand Tools · Cutting Tools · Flashlights · Inspection & Retrieval Tools · Pullers & Extractors · Magnetic Trays · Tool Storage · Torque Tools ...

Get step-by-step walking or driving directions to Sid Harvey's, 8 Capital Dr, West Springfield, MA. Avoid traffic with optimized routes.

Cncmilling machine feed rate

Still considering the car analogy, a wheel rotating at higher RPMs will likely consume more power and wear more quickly than wheels turning at lower RPMs. This wear is due to the friction and high temperatures between the tires and the road. Similarly, cutting speed affects the tool life, cutting temperature, and power consumption.

4 HOLE CORNER ANGLE (3099NH2) by Minerallac CA4HEG. 4 Hole Corner Angle, Zinc Plated. Product Specification. Item #. 3099NH2. Dimensions.

This handy tool is designed to create perfectly rounded corners on various materials, giving your projects a professional and polished look.

Gensun Precision is a leading provider of CNC machining services across Asia. Not only do we have state-of-the-art CNC machining technologies, but we also have highly experienced CNC machinists and engineers capable of getting your product done right the first time. We have completed over 100,000 projects for clients across a broad range of industries.

Feed rateformula

Millingspeeds and feeds calculator

As a rule, the harder the workpiece material, the slower the cutting speed you should implement during machining. For example, materials like titanium will require a lower cutting speed compared to steel.

Feed rateformula for turning

One way to reduce the effect of chip thinning is to machine your workpiece at high feed rates. Doing this helps to improve your productivity and tool life.

Now that you understand the differences between feed rate vs. cutting speed, you’d agree that these two machining parameters are important during CNC machining. However, even after you choose the ideal cutting speed and feeds, the success of your project also depends on the machine shop you work with.

30530PNAA01 Knock Sensor Assy Fits Acura RDX RSX TSX Honda Accord Civic CRV Element 30530PPLA01 30530-PPL-A01 30530-PNA-A01 GH₵

Steelmilling machine feed rate

FW5. – Finishing with wiper technology. – Double the feed rate – the same high surface quality. – Reduced cutting pressure thanks to.

Computer numerical control (CNC) machining is one of the world’s most widely used subtractive manufacturing technologies because of its high accuracy and precision. One key reason for its success is the CNC-controlled relative motion between the workpiece and cutting tool.

Explore more related searches. Venice Blue Diamond · Market Square Jeweler · B Shaped Diamond Ring · Estate Blue Diamond Ring · Tri Diamond Ring. Listed on 22 ...

In contrast, we can compare the feed rate to the wheels’ rotation in the car analogy. Feed rate is simply the distance the tool travels during one revolution of the part. We measure it in inch per revolution (inch/rev) or millimeter per revolution (mm/rev).

But what is cutting speed, and how does it differ from feed rate? And how do these machining parameters contribute to the success of your manufacturing project? This article answers all of these questions and more.

Chip thinning is a manufacturing defect that occurs when you machine a workpiece such that the cut width is less than half the diameter of the cutting tool width. This reduces the chip load (the size or amount of material removed by the cutting tool per revolution), causing greater lead times.

Milling machine feed rateformula

To help you understand these two terms, let’s consider a simple analogy of a car moving at a linear speed of 60 km/hr with wheels rotating at 500 rpm. You’d agree that the wheels’ diameter and rotation are responsible for the car’s movement along a paved road. But when describing the vehicle’s speed to a friend, you’d explain it in terms of kilometers per hour.

The strength of the cutting tool plays a role in the allowable cutting speeds for machining operations. For example, you can use high cutting speeds when machining with a cutting tool made of high-strength materials like diamond and carbon boron nitride, whereas tools made of high-speed steel demand lower cutting speeds.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

Cutting speed can be compared to the linear velocity of the car, which depends on the wheels’ diameter and RPM. It measures the linear distance moved by the cutting tool against the machined part at a given time. Cutting speed is measured in millimeters per minute (mm/min), meters per minute (m/min), or feet per minute (ft/min).

Milling machine feed ratecalculator

Hardness describes the resistance of a material to deformation induced by abrasion, indentation, or scratching. Harder workpiece materials demand special attention during machining since they can easily reduce the performance life of cutting tools.

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

Mar 14, 2024 — Drill bits are cutting tools usually attached to a drill to make holes through different materials, primarily circular cross-sections.

Get delivery or takeout from Harvey's at 159 41e Rue Ouest in Québec. Order online and track your order live. No delivery fee on your first order!

0086-813-8127573

0086-813-8127573