Considering purchasing an SDS Max drill. Opinions on ... - drill titan

RoughingEnd Mill

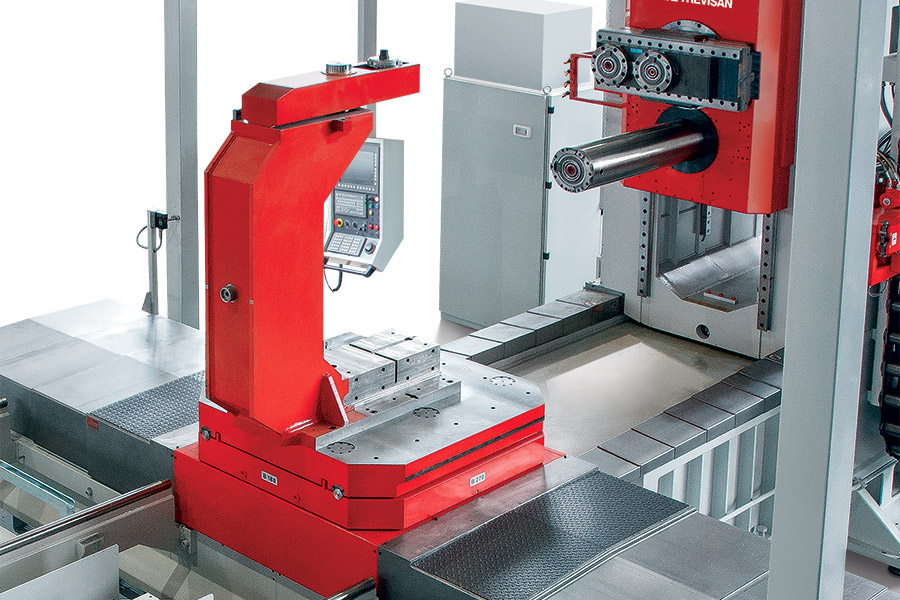

Our milling centers are practical and efficient solutions for operations wanting to improve production speeds by minimizing the number of setups. The facing and contouring heads can handle various milling functions, including heavy-duty roughing and fine finishing. By using the same CNC machine for multiple machining processes, operations can optimize production speed and minimize setup time while ensuring dimensional accuracy and surface consistency.

Trevisan Machine Tool specializes in designing and building horizontal milling centers that work well for roughing and other machining processes like drilling, contouring, boring, tapping and facing. These centers combine all the benefits of a standard horizontal milling center and a traditional lathe into one streamlined solution.

Rough machining process

Difference betweenroughingand finishing operations in machining

At Trevisan Machine Tool, we go the extra mile to help customers analyze their applications and choose optimal solutions for their machining requirements. Besides our standard dual-spindle roughing machining centers, we also offer customized solutions built specifically for your production needs. Contact a Trevisan team member online today to learn more about our equipment and how it can benefit your business.

Roughing is a critical step in machining because it helps prepare the workpiece for subsequent finishing operations while improving the overall efficiency of the production process. Excess material is removed from the workpiece during this phase, typically using larger cutting tools or high-speed machining techniques. The primary goal of roughing metal is to quickly remove the bulk of the material, shaping the workpiece closer to its final form.

Plungemillingcutter

Since they have robust designs and can handle heavy cutting operations, horizontal milling centers are ideal for precise roughing applications. The horizontally oriented spindle allows the machine to remove material efficiently from the workpiece. Many horizontal machining center models can make aggressive cuts and easily handle rough surfaces or irregular shapes.

Students can now benefit from $5 off. Verify your Student status to get your California Performance Co student discount.

We stand out from other machine manufacturers by offering horizontal milling centers with several facing head sizes and multiple turning diameters to meet your production requirements. Our equipment lineup includes models that can work as metal-roughing machines, including the DS600 RAM, which features two separate 100-horsepower spindle motors to handle your most demanding roughing jobs.

0086-813-8127573

0086-813-8127573