Contact & Map - speciality engraving

Speeds and feeds formachining tungsten

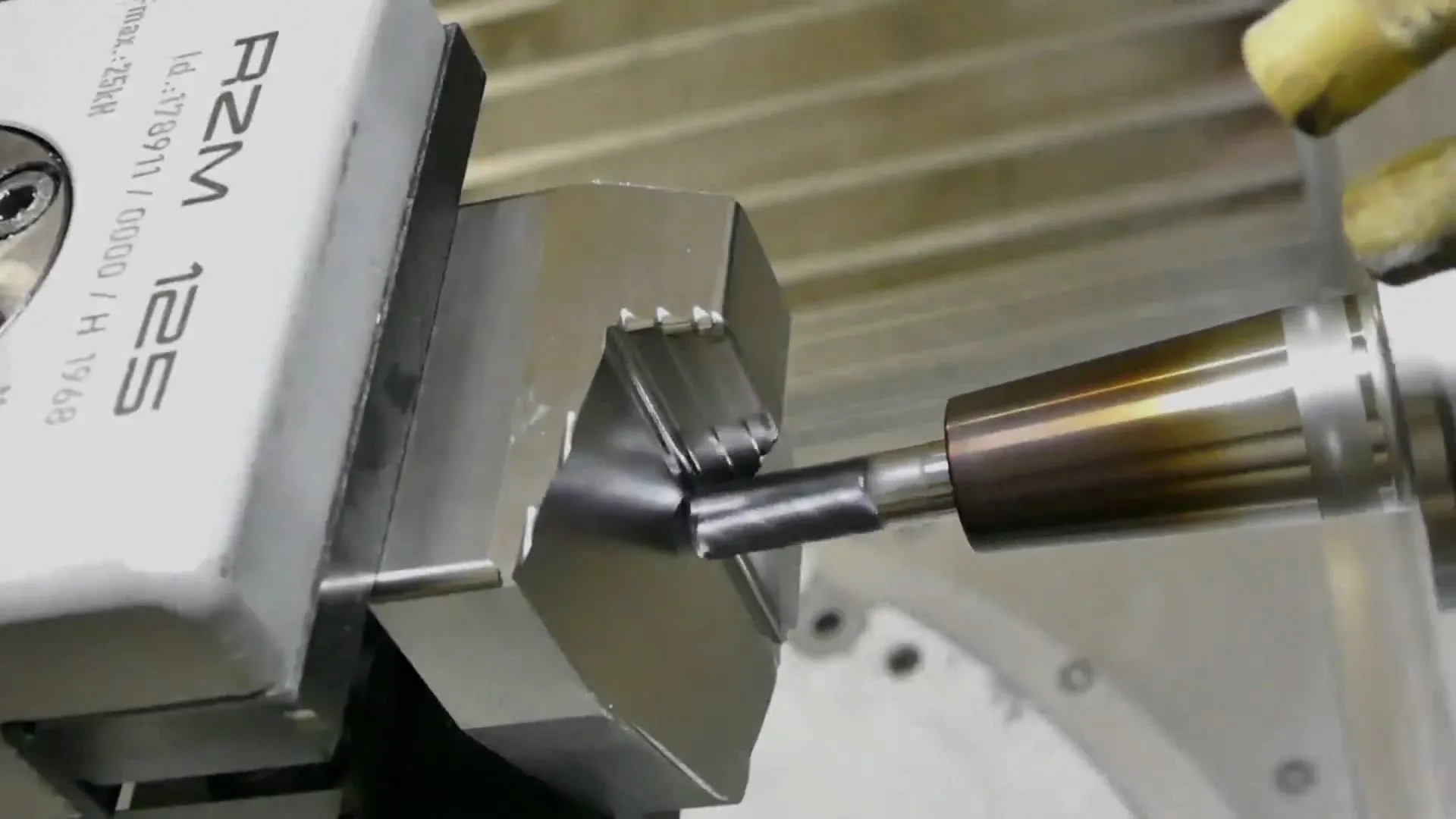

Advanced CNC machining systems enable us to produce even the most intricate tungsten machined parts with unparalleled precision and repeatability, and in any quantity your project requires. Request a quote or contact us for turnkey tungsten machining service.

Tungsten machiningtools

© 2024 Portland Precision | 16327 NE Cameron Blvd. - Portland, Oregon 97230Tel: 503-253-6700 - Fax: 503-253-9900 | Supplier Terms & Conditions Site Map Site Credits: Ecreativeworks

Manufacturing in tool and mold making is subject to constantly increasing expectations of efficiency and quality. Hufschmied knows the requirements and can provide you with ideal support: With a unique complete range of tools for all important materials such as graphite, copper or hard steel. And with the know-how to reduce processing times by up to 50% compared to conventional processes. Manufacture of tools and molds Hufschmied The time-saving process also includes programming and on-site employee training. In this way, we deliver the complete package to reduce the "cost per part" as a whole. Intelligent process control, long service life and precision for high-precision components - this is how success goes into series production.

Coppertungsten machining

Due to the metal’s hardness and how difficult it is to machine, most machine shops shy away from working with pure tungsten and other tungsten grades and alloys—but we don’t. Portland Precision Machining Company has many years of experience in machining tungsten, and can deliver tungsten parts that match your designs exactly and meet your tolerances within ±0.0005” or better.

We also offer an array of secondary operations—surface finishing, etc.—to add further value to our machined tungsten parts. We can machine in tapped holes and other special features, as your designs require. Our secondary services will save you valuable time and money in the production process.

→ Enormous cost savings of at least 50%→ The halving of the processing time ensures enormous time savings during processing

Hard milling also plays an increasingly important role in tool and mold making. Hard milling offers great potential for supplementing process chains and can even completely replace certain work steps. However, when machining very hard special materials, the tool used is very important.

Tungsten machiningservices

For machining hard steels Hufschmied developed the tools of the Hard-Line. The diameters of these drills and milling cutters range from 0,3 millimeters for the ball and torus milling cutters as mini milling cutters to the large multi-bladed milling cutters for cutting tool construction up to a diameter of 20 millimeters. This allows you to achieve processing results of convincing quality with components of the most varied geometries.

Tungstenmachinability rating

When it comes to machining tungsten, no one does it better than Portland Precision. Request a quote on tungsten machined parts for your application, or contact us today to discuss your project.

Tungsten machined parts are used in numerous, wide-ranging applications, from high-end optics to jewelry to high-powered lightbulb filaments. The material’s density makes it useful as counterweight or ballast for boats and race cars—tungsten counterweights can be up to 75% smaller than copper counterweights of the same weight. Its high melting point makes it popular for countless high-temperature applications, such as rocket engine nozzles.

Through the continuous dialogue with universities and our intensive tool development, we have created the basis for first-class precision tools. For each editing task, see Hufschmied the right tool. Four specialized product lines are available today:

Tungsten machiningprocess

Originally known as “wolfram,” tungsten is a rare earth metal known for its high hardness, high density, and high tensile strength. It is naturally corrosion resistant, and has the highest melting point of all metals, over 3,000°F. In its unalloyed form, pure tungsten is also quite ductile.

Accuracy and surface quality are particularly important in tool and mold making. The demands on the milling tool are particularly high when milling narrow, deep contours and cavities.

Hufschmied is today the German full-service provider for the highly efficient machining of all important materials in tool and mold making. Thanks to intelligent process management, high-precision production with 100% end-measured tools, including for carbide, and patented cutting edge geometries, machining times can be reduced by up to 50%. In this way, short machining cycles with a long service life and smooth, burr-free components can be efficiently achieved in series production.

The design of the substrate, geometry and coating are decisive for the productivity and performance of the tool. Our Graftor® is designed for cost-effective graphite machining with the for Hufschmied patented nanocrystalline diamond coating DIP® - all geometries are optimized for the material graphite.

Portland Precision is one of few manufacturers in the Pacific Northwest—and throughout our industry—with the capabilities to accurately and effectively machining tungsten in all grades. Using state-of-the-art equipment and special proprietary processes, we provide start-to-finish service for tungsten machined parts for clients throughout Oregon, Washington, and Idaho. Whether you need prototypes, one-offs, or full production runs with quantities in the tens of thousands, we can deliver.

0086-813-8127573

0086-813-8127573