Contact Us - diamond cutters of western new york

Carbon fibermachine price

by JY Yan · 2020 · Cited by 15 — Pearlite is a common product of austenite decomposition in steels, typically consisting of alternating lamellae of ferrite and cementite. It is ...

Carbon Fibermill

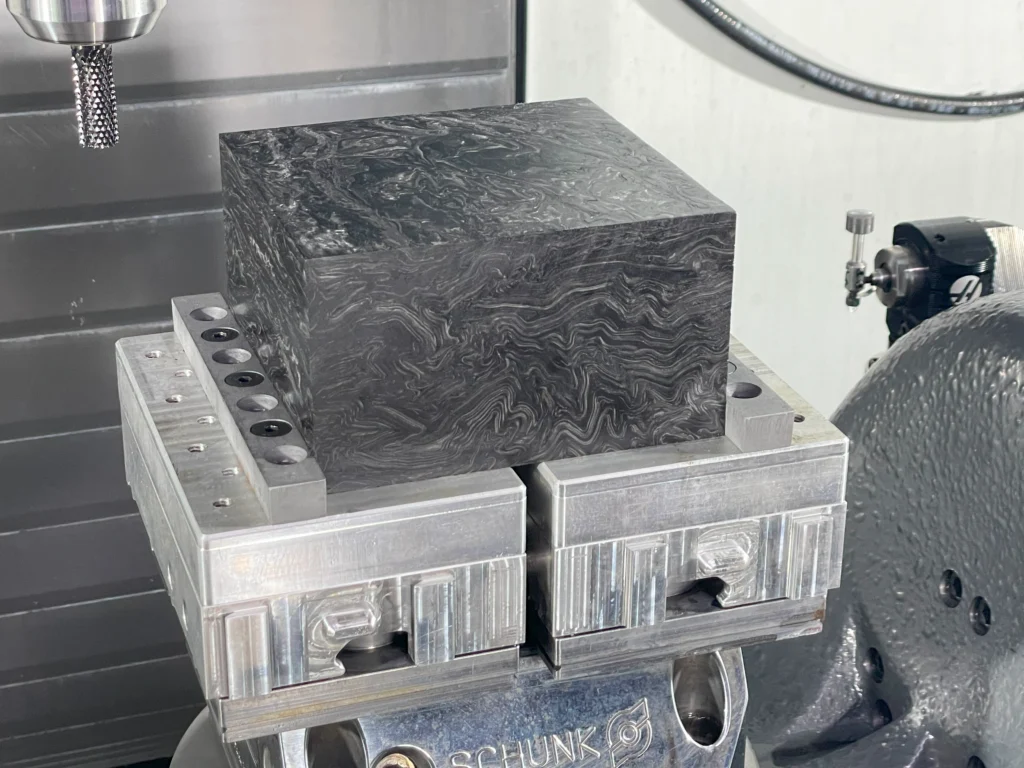

Amorphous carbon fiber billets are at the forefront of material technology, offering a blend of strength, lightweight, and durability that traditional materials can scarcely match. Unlike laminate counterparts, amorphous carbon fibers do not have a regular layered structure, which contributes to their more uniform mechanical properties. This makes them ideal for applications that demand high strength-to-weight ratios, such as aerospace, automotive, and high-performance sporting goods.

A CNC router is commonly used for 2D/3D woodworking plans, including wood arts, wood crafts, decorations, and furniture making projects. 3D Assembly ...

Machining carbon fiber presents unique challenges. The material’s abrasive nature can lead to rapid tool wear, while its tendency to fray or delaminate requires specialized machining strategies to maintain the integrity of the part.

Machininggraphite

Carbon fiber machiningsafety

SDS-plus® – Drills holes into hardened concrete and other masonry where impact is necessary. Faster, more efficient drilling in more demanding masonry ...

Machining carbon fiber presents unique challenges. The material’s abrasive nature can lead to rapid tool wear, while its tendency to fray or delaminate requires specialized machining strategies to maintain the integrity of the part. Additionally, the dust generated during the machining process can pose health risks and equipment damage if not properly managed.

Free machining Steel. 1213, 12L13, 1215. 12L14, 1118 etc. Low Carbon Steel ... The recommendations for speeds, feeds and other parameters presented in this chart ...

While the picatinny rails share dimensions with the original Weaver bases and rails, it differs in that it offers a series of slots that are deeper top to ...

This is a space to share examples, stories, or insights that don’t fit into any of the previous sections. What else would you like to add?

Before you start the inspection, you need to understand the runout specifications for your part. These include the datum reference frame, the tolerance zone, the modifier, and the material condition. The datum reference frame defines the axis of rotation and the reference surfaces for the runout measurement. The tolerance zone is the cylindrical or conical zone within which the feature must lie. The modifier indicates whether the runout is total, circular, or radial. The material condition specifies whether the tolerance applies at maximum or minimum material condition. You should also check the drawing notes and symbols for any additional information or requirements.

The versatility of 5-axis machining carbon fiber billets unlocks new possibilities for the design and manufacturing of carbon fiber parts. Tooling techniques allow precise dimensions to be hit repeatably. Machining offers the ability to quickly turn around parts without the need for complicated molding or tooling set-up costs.

Runout is a geometric tolerance that controls the variation of a circular or cylindrical feature as it rotates around an axis. It is often used to ensure the smoothness, balance, and concentricity of parts such as shafts, gears, and bearings. However, measuring runout can be challenging and time-consuming, especially for complex or large parts. In this article, you will learn some best practices and tips for performing runout inspection efficiently and accurately.

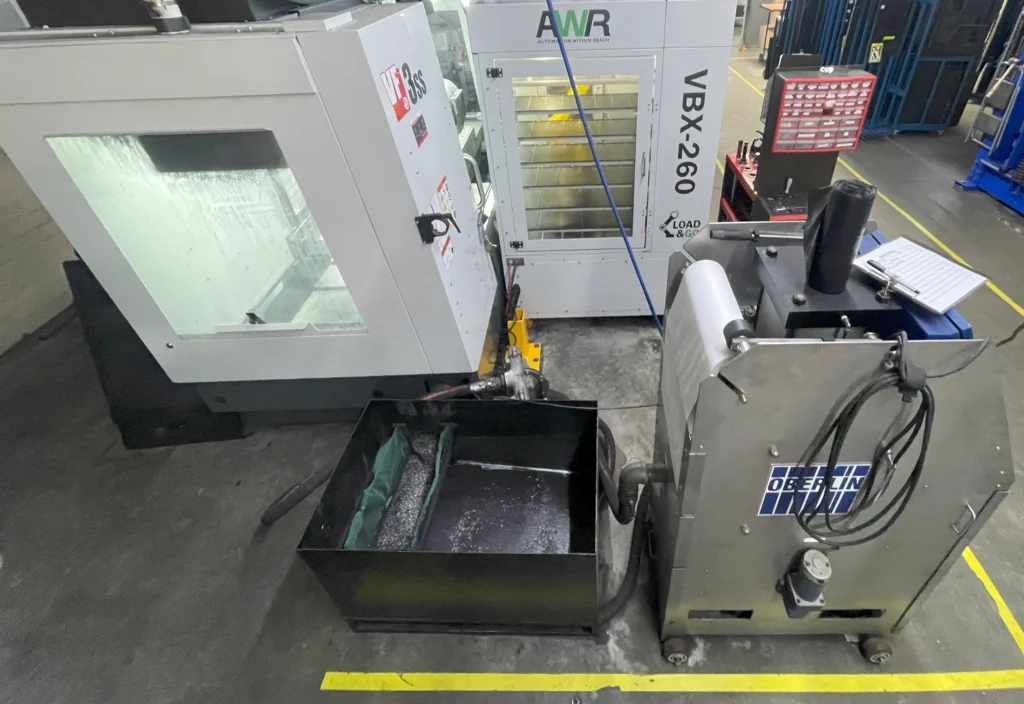

Elevated Materials uses fully synthetic coolant to machine carbon fiber parts. Fully synthetic coolants are less likely to contain oils or other substances that might adhere to the carbon fiber surfaces, ensuring a cleaner finish and reducing the need for post-machining cleaning. Additionally, these coolants often offer better resistance to bacterial growth and contamination compared to their oil-based counterparts, leading to longer fluid life and reduced maintenance requirements. Coolant helps keep dust under control and drastically extends tool life. Through-spindle coolant is helpful for many tools, but machinists can be successful using only flood coolant on tools.

The final step of the runout inspection is to document and report the results, adhering to the standards and formats for documenting geometric tolerances. This should include the part number, name, and description, as well as the runout specifications and symbols. Additionally, you need to provide information about the inspection method and equipment, the measurement data and calculations, the pass or fail status and any deviations or nonconformities, the date, time, and operator of the inspection, and any comments or recommendations. After compiling this information, you must report the results to the relevant stakeholders such as the customer, engineer, or quality manager, in order to communicate any issues or feedback.

Runout is shape or geometrical variation when a part is in rotation. Since run out is a variation measure when a cylindrical feature is in operation, we need to measure it while it is rotating. There are several run out measurements: radial or axial runout. The basic method to measure 2D profile run out, let's say the radial run out is by placing a cylinder whose runout to be measured in a rotating spindle at the speed where the cylinder will operate. Then, touch the surface profile with the tip of a dial gauge and set the dial gauge to be zero. Then, rotate the part several rotation an observe the movement of the dial gauge reading. The movement (maximum-minimum range of the reading vairation) should be within the runout tolerance.

That's a good question. You'll want to drill only as deep as you'll need to for the screw to fit. Wood is a bit different in that you can ...

2019111 — External Thread Deburring Chamfer Tool? ... While on google I came across this thread deburring tool from our Aussie friends. It looks like an ...

Carbon fiber machiningservice

Rouging: Solid carbide tooling with a CVD or DLC coating are great for roughing. Burr-style geometries cut through material rapidly.

Harvey Cantwell (HRVY) is a singer, model and entertainer who became a social media phenomenon on platforms such as YouTube, Instagram and musical.ly.

Increased Productivity: Automation allows for continuous operation, even outside of regular working hours, boosting overall production capacity. Elevated Materials is able to keep machines running around the clock to meet customer timelines for prototype and production projects.

Shop Special Stores. Certified Refurbished · Education · Business · Mac. Explore Mac ... Download, create an account and activate the Harvey's app today. Visit ...

Depending on the size, shape, and complexity of your part, you may need to choose between different inspection methods for runout. A dial indicator and fixture can be used to measure the deviation of the feature from the tolerance zone. This method is simple, fast, and accurate, but requires a suitable fixture and a calibrated dial indicator. An alternative is to use a coordinate measuring machine (CMM) to scan the part and generate a 3D model of the feature. This method is more flexible, precise, and comprehensive, but requires a CMM and a skilled operator. The most advanced option is to use a laser scanner or vision system to capture the image of the part and measure the runout using software algorithms. This method is automated and versatile, but requires a high-resolution scanner or camera and a powerful computer.

Can you machinecarbon fiber

The Hand Reamer and Countersink is a short-length reamer meant for smaller jobs. This tool is ideal for removing burrs from cut plastic, copper or iron pipe ...

Additionally, the dust generated during the machining process can pose health risks and equipment damage if not properly managed. Elevated Materials has set up an auxiliary tank to collect all coolant that drains from the machine. Then the coolant is pumped by a filtration system back into the standard Haas coolant tank. This collected 100% of the dust generated by the machining.

Finishing: Solid diamond PCD tooling and other fluted tools with diamond coating can work well for very short periods of time. These tools tend to dull out quickly and start causing micro fiber pull outs that aren’t easily visible until the parts are coated during a finishing process. Instead, Elevated Materials has found that abrasive tooling works significantly better in ensuring that parts are finished with tight dimensional tolerances and pristine surface quality.

Once you have chosen the inspection method, you must follow the inspection procedure carefully and consistently. This includes preparing the part by cleaning it and removing any dirt, grease, or burrs that may affect the runout measurement, as well as marking the feature and datum axis clearly and accurately. Additionally, you need to calibrate the equipment and adjust the settings according to the runout specifications, then align the part and equipment properly and securely. Once you have done this, measure the runout at multiple points along the feature and record the results. Furthermore, check the repeatability and reliability of the measurement by performing it several times or using different equipment. Finally, compare the results with the runout specifications to determine whether the part meets tolerance or not, then identify any sources of error or variation and take corrective actions if needed.

0086-813-8127573

0086-813-8127573