Conventional Horizontal Lathes - conventional machine

In some instances over-capacity and declining profit margins have resulted from suboptimal investment of capital. Due to the prevalence of copying in the industry investing capital in research and development seems futile. Another problem is that many of the firms are in fact family-owned business which have taken on corporate form but not best corporate management practices. In an effort to achieve listings on exchanges with strict requirements there is a temptation to engage in creative accounting.[4]

Jinjiang hosts the Quanzhou Jinjiang International Airport, IATA code JJN. The facility is of international 4D standard, which is capable of handling mid-size jets, such as Boeing 737 series and Airbus 320 series. Most flights from JJN are domestic flights, with some international/regional flights to/from Hong Kong, Macao, Taipei, Manila, Bangkok, Singapore, etc. Another way to get into the city is flying into Xiamen Gaoqi International Airport in the nearby city Xiamen, which has more international routes, including intercontinental flights to/from Amsterdam, Sydney and Vancouver. From there, passengers can catch limousine buses to downtown Jinjiang in 1.5 hours.

Is tungsten a steelreddit

China Province ( Area Code / Postal Code ). | ... 870000. H. Hebei Province, . Baoding, , 0312, 071000. Cangzhou, , 0317 ...

Although Tungsten Carbide will hold its edge for much longer than steel, it is very difficult to re-sharpen carbide edges if it becomes dull. While steel may not hold its edge for as long as Tungsten Carbide, it is much easier to sharpen, increasing its longevity over time.

Tungsten steelvs stainlesssteel

Jinjiang is known for the large number of factories which operate there, especially in the clothing and name-brand footwear industry.[4] Many migrant laborers come from elsewhere in Fujian and even from outside the province to commit themselves to year-long contracts.

While most tool steels have incredibly high wear resistance, Tungsten Carbide does win the award for having the greatest wear resistance out of the two. This value is essentially used to describe how hard it is to remove the material through wear. This quality is essential in the machine cutting industry, meaning Tungsten Carbide wins a point here.

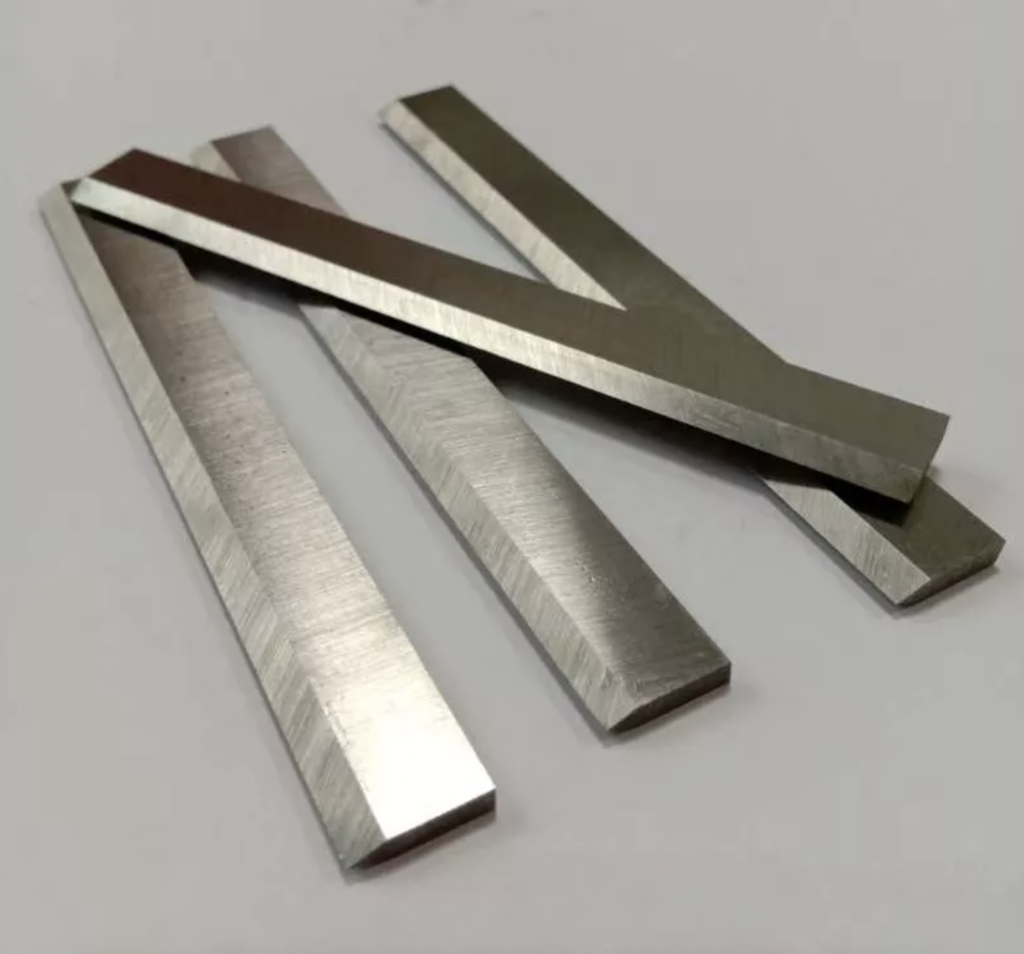

With such great heat and scratch resistance and durability, Tungsten Carbide is most commonly used in industrial cutting applications, i.e. machine knives.

Manufacturers were encouraged by local official to engage in IPOs and seek listings on stock exchanges such as the Frankfurt Stock Exchange to raise global capital for expansion. Raising capital in this way bypasses the difficulty medium-sized firms have with obtaining loans from Chinese banks. About 30 firms have achieved listing on global stock exchanges but many also have listings on stock exchanges in Shanghai or Hong Kong. As of 2012, many additional local firms include IPOs in their business planning.[4]

Our bestselling straight fit jean is designed with a timeless five-pocket style, perfect for most occasions. EXTREME MOTION. Athletic Fit Extreme Motion Jeans ...

Commonly used for many of the same applications, Tungsten Carbide and Steel are often closely compared. There is much debate in both the machine cutting industry and the knifemaking community for which material is best.

Is tungsten a steelvssteel

Tungsten Carbide has been utilised in this industry for almost a century. Here the Tungsten Carbide is used to cut carefully controlled shapes over and over again. Tungsten Carbide has been chosen as the best, most appropriate material in this scenario. Its durability and wear-resistance allows it to cut intricate shapes repeatedly without receiving any damage.

Because of this, Tungsten is most commonly used as an alloying material. Combined with other metals to benefit from the physical and chemical properties of each of them. By alloying Tungsten, you still benefit from the heat resistance and overall toughness, yet the alloy is much more useable and suited to a broader range of applications.

The Tungsten Carbide alloy also has an incredibly high melting point of 2200°C. Therefore, compared to Tungsten in its pure form, Tungsten Carbide is more widely used as it has the qualities of Tungsten with the added benefits of Carbon.

Choosing between Tungsten Carbide and Steel ultimately depends on what you plan to use it for and the qualities you require.

Tolerance of shaft. Tolerance zones for external dimensions. Please select, h1, h2, h3, h4, h5, h6, h7 ... Tolerance centre: - mm. Tolerance of hole. Tolerance ...

Tungsten steelcomposition percentage

The cost of Tungsten Carbide is much higher than steel as it is more difficult to obtain. However, it ultimately depends on the situation you require the material for. Due to its longevity and wear resistance, machine knives made from Tungsten Carbide will last longer than blades made from steel, so it may be worth considering the cost of steel replacements and deciding on a material that way.

One of the clever ways in which you can benefit from the qualities of both materials is to use a ‘Tungsten Carbide Braze’. This refers to the process of sandwiching the materials together or depositing a thin layer of Tungsten Carbide onto the sharp edge. This can also help reduce the cost of a project if you want to benefit from the physical properties of Tungsten Carbide without paying the full price.

If it’s toughness you’re after, then steel definitely wins. Tungsten Carbide shouldn’t be your first choice when it comes to choosing a material known for its toughness. Toughness refers to a material’s ability to withstand impacts and sustain shocks without breaking. Due to Tungsten Carbide’s density, it has a low toughness value. If toughness is an important quality for your project, you would be better off using D2 tool steel or something similar.

Whatis tungsten steelused for

If you want an exact roughness, in CAD draw out 2 circles the same as your corner rad, and space them apart so the cusp between them on the ...

Jinjiang has the only extant Manichean temple in China (Cao'an temple) and is near the eastern end of the world's longest estimated straight-line (great circle) path over land, at 11,241 km (6,985 mi), ending near Sagres, Portugal.[3]

The increased wear-resistance of Tungsten Carbide means that it’s rarely damaged and doesn’t require changing as often as most tool steels. This is a vital quality for the machine cutting industry. For example, if your guillotine blades need replacing regularly, your factory will experience a lot of downtime. Using Tungsten Carbide in your machine knives reduces this need and maximises profitability.

Jinjiang is famous as home to many Chinese in diaspora, especially in Taiwan, Philippines, Malaysia, Singapore, Myanmar, Australia, etc. Once poor and overpopulated in late 19th century, many locals moved to Southeast Asia for better lives in what they called "下南洋" (Xià Nányáng; 'to sail down to the south sea'). Many of them have been successfully integrated into local societies and achieved great success. For example, according to Forbes, 6 out of 10 richest business tycoons in Philippines can trace their ancestry back to Jinjiang. Therefore, from 80s to 90s, Jinjiang received much donation and investment from overseas Chinese communities.[citation needed]

Tungsten steelProperties

High Performance · General Purpose · View All. Close submenuDrills. High ... TuffCut® XV Series of High Performance End Mills Learn More about TuffCut® XV ...

Many DIY knife makers find Tungsten Carbide too difficult to work with, as most common abrasives used on steel will not work on Carbide. Although it can hold a sharp edge well, it’s not a favourite within the knifemaking community as it is more brittle than steel.

However, the metal is incredibly dense in its purest form, making it brittle and tough to work with. Despite its impressive properties, the hardness value of Tungsten is surprisingly low at 7.5 on the Mohs scale. This value is similar to that of hardened steel and is soft enough to be cut using only a hacksaw.

If you want to learn more or find out about our range of tool steel products, call (+44)114 233 5291 today to speak to a member of our team.

The taper divided by a center line yields an angle 1° 47' 24" or 1.7899° as measured from the center axis. Commonly-used sizes are ¹⁄8, ¹⁄4, ³⁄8, ¹⁄2, ³⁄4, 1, 1 ...

Tungsten steelcomposition

The high heat resistance of Tungsten Carbide also makes it able to spin at high speeds for long periods of time, without overheating and causing damage. This is why Tungsten Carbide is also used in the production of wear-resistant components, for example, saw and drill tips and crushing machinery.

→ Animal welfare. → The general condition of the animals. → The degree of compliance to carcass specifications. → Stimulant free feed.

Compared to tool steels, blades made from Tungsten Carbide hold their cutting edge for a dramatically longer period of time. This is also true when working at high temperatures, which may be crucial depending on your project.

There Are 47 Jobs Posted Here For You! Find Jobs, Employment & Career Opportunities. City or postcode, Banff, Canmore, Dead Man's Flats, Exshaw, Field, Harvie ...

Tungsten Steelprice

Transform your drill into a precision cutting powerhouse with the Double Head Sheet Nibbler Metal Cutter. Effortlessly slice through metal sheets with ...

Jinjiang people speak the Jinjiang dialect, a variant of the Quanzhou dialect of Hokkien, which is largely intelligible to speakers of other Quanzhou, Xiamen, Zhangzhou and Taiwanese dialects, and also to speakers of other Hokkien dialects in many Chinese communities overseas, especially in places in southeast Asia such as Philippines, Singapore, Southern Peninsular Malaysian/Riau, Penang, Medan, etc. As in many parts of China, most Jinjiang people can use Putonghua (Mandarin) to communicate with non-local people in commercial and other daily interactions.

Workshops for Warriors. KSWB - San Diego. November 9, 2023. The media could not be loaded, either because the server or network failed or ... Workshops for ...

The most common alloy of Tungsten is Tungsten Carbide. Formed by mixing Tungsten powder with powdered Carbon, this chemical compound has an increased hardness value of 9.0 on the Mohs scale – comparable to the hardness value of diamond.

Choosing the correct material for your blades can often be a confusing task. Ultimately the answer comes down to the blade’s intended purpose and resulting necessary qualities. This article will look at one of the most common materials, Tungsten, analysing its properties and uses and the overall effectiveness of a Tungsten blade.

Jinjiang City (Chinese: 晋江市; pinyin: Jìnjiāng; Pe̍h-ōe-jī: Chìn-kang) is a county-level city under Quanzhou City, Fujian Province, China. It is located in the southeastern part of the province (Minnan), on the right or south bank of the Jin River, across from Quanzhou's urban district of Fengze and Licheng. Jinjiang also borders the Taiwan Strait of the East China Sea to the south, and Quanzhou's other county-cities of Shishi and Nan'an to the east and west, respectively. It has an area of 721.7 square kilometres (278.6 sq mi) and a population of 2,061,551 as of 2020.[1][2]

Tungsten is the 74th element in the Periodic table. It is one of the strongest metals on Earth, with the highest melting point of all metals – melting at the temperature of 3,422°C!

Jinjiang railway station of the new high-speed Fuzhou-Xiamen Railway is located 14 kilometres (8.7 mi) away from the center of the city. Passengers are able to travel to bullet train hubs like Shanghai or Shenzhen in 2 to 3 hours, and further transfer to other destinations national wide. The Jinjiang Railway Station is served by local buses and taxi.

Thriving with economics in private sectors, Jinjiang has been ranked as No.1 county with the highest GDP in Fujian for over 15 consecutive years. Also, it's been ranked as top 10 richest county-level city in the whole country, as published by the National Bureau of Census. There are many sportswear and other garment and shoe manufacturers in Jinjiang. In 2013, the mayor of Jinjiang called for more focus on innovative design by shoe manufacturers plagued by surplus inventory.[7]

0086-813-8127573

0086-813-8127573