Copy Cutters: Round Inserts High Metal Removal Rates - round insert milling cutter

Millinginsert types

We drive progress across a wide range of sectors, including battery materials, thermoplasticcomposites, and renewable materials. Explore our diverse products and solutions portfolio.

Embark on a journey of scientific discovery with Syensqo. Learn more about our teams, our job opportunities, and our recruitment process – in locations around the world.

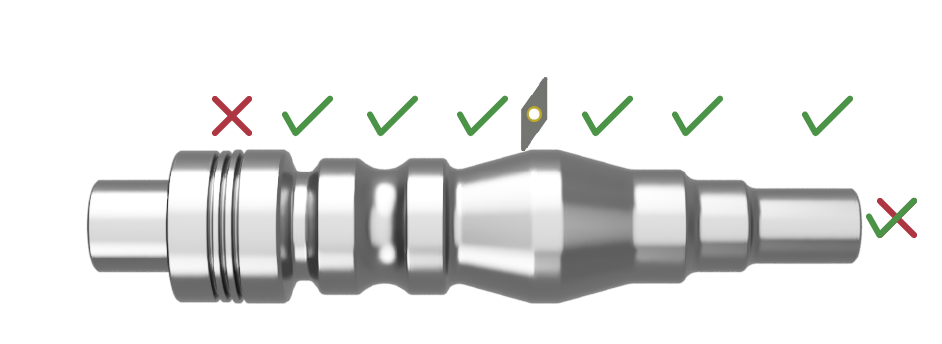

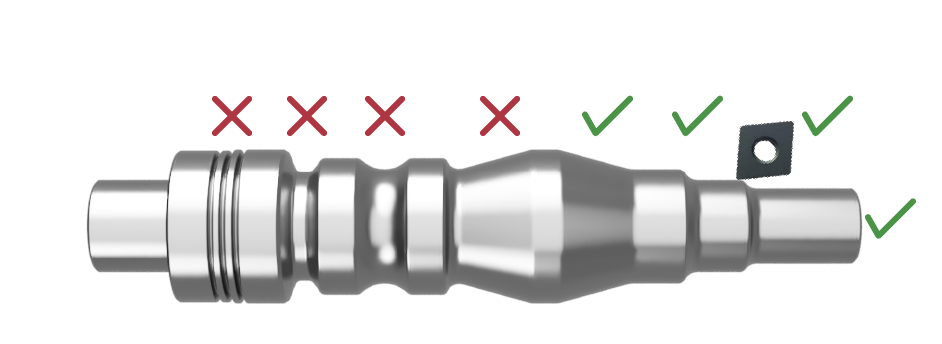

Insertgeometry chart

We care deeply about our impact on people, environment, and society. Discover Syensqo’s sustainability and philanthropy work and how we’re investing in positive change.

Carbideinsertidentification chart PDF

Trillium will supply Syensqo with bio-ACN from Trillium’s planned commercial asset, and Syensqo will evaluate bio-ACN for carbon fiber manufacturing as part of its long-term commitment to developing sustainable solutions from bio-based or recycled sources.

Overall, W type inserts offer versatility, good cutting edge strength and cost-effectiveness, making them a very popular choice for roughing and semi-finishing turning operations. However, their limitations in finishing cuts, higher cutting forces, limited precision and size constraints should be considered when selecting the appropriate insert for a specific turning application.

Syensqo announced today that it has signed an agreement with Baker Hughes to partner on innovative solutions implementing Thermoplastic Composite Materials in offshore flexible pipes and risers for the oil and gas industry.

V Type inserts, have a distinct shape with a 35° cutting edge.Here are the advantages and disadvantages of using V-shaped inserts in turning:

W type inserts (with 80° edge angle) are commonly used in turning operations, particularly for roughing and semi-finishing applications. Due to their versatility and effectiveness these inserts have specific advantages and disadvantages that are important to consider.Advantages of W type Inserts in Turning:

Syensqo has joined the ThermoPlastic Composites Research Center (TPRC), the world-leading research, development and innovation center for thermoplastic composites (TPC) focused on enabling the use of this technology in large volume applications and eliminating technological barriers towards its widespread adoption.

It’s important to note that the advantages and disadvantages of V-shaped inserts can vary depending on the specific application, cutting conditions, and the material being machined. Proper tool selection and setup, along with considerations for cutting parameters, are essential for achieving the best results.

Syensqo and Penso successfully developed the composite design, material and manufacturing technologies required to create a modular, multi-material Body-In-White structure suited for large production volume.

Investing in Syensqo means investing in a pioneering, future-focused business dedicated to enabling a sustainable future. Explore our commitment to our investors and shareholders.

Turning insertchart

C Type (80° diamond) inserts are commonly used in turning operations due to their versatility and effectiveness. Here are some advantages in turning:

Syensqo and SGL Carbon have entered into a joint development agreement (JDA) to bring to market the first composite materials based on large-tow intermediate modulus (IM) carbon fiber.

CNCturninginserts

Syensqo and Wichita State University’s National Institute for Aviation Research (NIAR) celebrated the official opening of their joint Manufacturing Innovation Center dedicated to enabling the future of flight through advances in composite technologies.

We also provide advanced composite and adhesive materials for extreme-demand environments, radical temperature changes, aircraft material expansion and contraction and other external conditions.

Innovation is at the heart of our business. Find out how our innovation focus informs our four Growth Platforms and our Syensqo Ventures investment portfolio.

Turning insertGuide

Combining 50 years of technology heritage, a comprehensive product portfolio and expertise in design materials and process engineering to deliver innovative customer solutions that maximize technology capability and simplify manufacturing.

It’s important to note that the advantages and disadvantages of D type inserts can vary depending on the specific cutting conditions, workpiece material, and the intended application. Manufacturers and machinists should consider these factors alongside their specific requirements to make informed decisions about insert selection.

It’s important to note that the advantages and disadvantages listed here are general observations and may vary based on specific machining conditions, workpiece materials, and machine tool capabilities. Manufacturers and machinists should consider these factors along with their specific requirements when choosing the appropriate inserts for turning operations.

0086-813-8127573

0086-813-8127573