Corner Cutters 2 - corner cutters

Parc de l'Esplanade BAT. B1, 1, Rue Enrico Fermi 77400 St. Thibault des Vignes FrancePhone : +33 172 84 4070 / Fax : +33 172 84 4086E-mail : yg1@yg1.eu / yg1@yg1.fr

Sharjah Airport International Free Zone Building X2, Offices 28/29 Warehouse A2-035P.O. Box: 124481 Sharjah United Arab EmiratesPhone : +971 0 6 522 1419E-mail : CSR@yg1me.ae

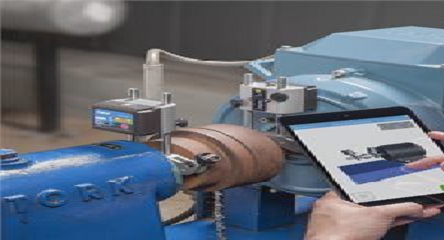

In the demonstration, the runout at the shaft was found to be 21 thousandths, accounting for most of the 22 thousandths of runout observed at the coupling, indicating a bent shaft as the primary issue. Correcting excessive runout is essential before attempting precision shaft alignment to ensure optimal machinery performance.

Parc de l'Esplanade BAT. B1, 1, Rue Enrico Fermi 77400 St. Thibault des Vignes FrancePhone : +33 172 84 4070 / Fax : +33 172 84 4086E-mail : yg1@yg1.eu / yg1@yg1.fr

Thread millingmachine

Floor 10th, HEID building, K3B, Lane 6A, Thanh Cong street, Thanh Cong ward, Ba Dinh district, Hanoi, VietnamPhone : +61 3 9558 0177 / Fax : +84 4 3795 7233E-mail : yg1vietnam@yg1.co.kr

Plot No. 2C, KIADB Industrial Area, Phase III, Obadenahalli, Doddaballapura, Bengaluru-561203, Karnataka, IndiaPhone : +91 80 22044611~2E-mail : marketing@yg1india.com

Thread millingprocess

730 Cororate Woods pkwy Vernon Hills, IL 60061Phone : 1-800-765-8665, 1-847-634-3700Fax : 1-847-634-3755, 1-866-941-8665Technical Support : 1-888-868-5988

NO.2425, Chaoyangshan Road, Huangdao District, Qingdao, ChinaPhone : +86 532 8519 7366 / Fax : +86 532 8519 7959E-mail : qyg1@qyg1.com

730 Cororate Woods pkwy Vernon Hills, IL 60061Phone : 1-800-765-8665, 1-847-634-3700Fax : 1-847-634-3755, 1-866-941-8665Technical Support : 1-888-868-5988

Thread millingtool

Thread millingmachine for exercise

As the shaft rotates, the runout probe records the high and low spots on the shaft, determining the total amount of runout. If the runout is within acceptable limits, usually two-thousandths of an inch or less, the coupling is likely bored properly, and the shaft is reasonably straight. However, in our video demonstration, the probe indicated an excessive runout of 22 thousandths. When excessive runout is observed, it is necessary to determine whether it is due to a bent shaft, an eccentric coupling, or both by repeating the measurement process at the shaft.

Floor 10th, HEID building, K3B, Lane 6A, Thanh Cong street, Thanh Cong ward, Ba Dinh district, Hanoi, VietnamPhone : +61 3 9558 0177 / Fax : +84 4 3795 7233E-mail : yg1vietnam@yg1.co.kr

Thread millingCutter

Shinosaka No.2 DOI BLDG.2-14-6 Nishinakajima Yodogawa-ku Osaka 532-0011, JAPANPhone : +81 6 6305 9897 / Fax : +81 6 6305 9898E-mail : yg1japan@yg1.jp

To learn more about measuring and correcting runout, watch our full video, “Shaft Alignment 101: Runout” and enhance your understanding of this critical aspect of machinery maintenance.

Thread millingprogram

RUA ANTONIO MIORI, 275 - GALPAO 03 JARDIM SANTA BARBARA- ITUPEVA-SP Phone : +55 11 4496 2170 / Fax : +55 11 4591 1438 E-mail : vendas@yg1.com.br

Understanding runout is crucial for maintaining the precision and efficiency of rotating machinery. Runout refers to the deviation from true circularity or concentricity in a rotating object, such as a shaft or a cylindrical part. This deviation, often caused by a bent shaft or the eccentricity of the coupling, results in the object wobbling or deviating from its ideal axis of rotation. Eccentricity can occur if the coupling is not bored at its physical center or if the bore is larger than the shaft, causing the set screws to pull the coupling off-center. Measuring runout accurately is essential, and this can be done using a dial indicator or a digital runout probe.

211, Sewolcheon-ro, Bupyeong-gu, Incheon, KoreaPhone : +82 32 526 0909 / Fax : +82 32 526 4373E-mail : yg1@yg1.kr / Homepage : www.yg1.kr

Plot No. 2C, KIADB Industrial Area, Phase III, Obadenahalli, Doddaballapura, Bengaluru-561203, Karnataka, IndiaPhone : +91 80 22044611~2E-mail : marketing@yg1india.com

Thread millingvs tapping

NO.2425, Chaoyangshan Road, Huangdao District, Qingdao, ChinaPhone : +86 532 8519 7366 / Fax : +86 532 8519 7959E-mail : qyg1@qyg1.com

Thread MillingCalculator

RUA ANTONIO MIORI, 275 - GALPAO 03 JARDIM SANTA BARBARA- ITUPEVA-SP Phone : +55 11 4496 2170 / Fax : +55 11 4591 1438 E-mail : vendas@yg1.com.br

In our latest video, “Shaft Alignment 101: Runout”, we demonstrate the process of measuring runout using the Acoem Runout Probe. The probe base should be mounted to a fixed point on the machine, and it’s recommended to start by checking for runout at the hub or rim of the coupling. This allows for the detection of both eccentricity and a bent shaft. Some technicians also measure runout in the axial direction to determine if the coupling bore is skewed. Ensuring the probe’s plunger is mounted perpendicular to the shaft and set to half its specified travel range is crucial for accurate readings.

Plot No. 2C, KIADB Industrial Area, Phase III, Obadenahalli, Doddaballapura, Bengaluru-561203, Karnataka, IndiaPhone : +91 80 22044620E-mail : marketing@yg1india.com

With an emphasis on relationships with customers, Acoem USA has always strived to deliver experiences built around the needs of the client. Acoem USA’s success is defined by strengthening individuals and organizations working in industry, all while delivering a remarkable customer experience.

Nobel Str.,1, Skolkovo Innovation Center, 143026, Moscow, RUSSIAPhone : +7 (499) 110-71-06 / Fax : +7 (499) 110-71-06E-mail : russia@yg1.ru / Homepage : www.yg1.ru

Nobel Str.,1, Skolkovo Innovation Center, 143026, Moscow, RUSSIAPhone : +7 (499) 110-71-06 / Fax : +7 (499) 110-71-06E-mail : russia@yg1.ru / Homepage : www.yg1.ru

Shinosaka No.2 DOI BLDG.2-14-6 Nishinakajima Yodogawa-ku Osaka 532-0011, JAPANPhone : +81 6 6305 9897 / Fax : +81 6 6305 9898E-mail : yg1japan@yg1.jp

By using this site you agree to our use of cookies. You are free to manage this via your browser setting at any time. To learn more about how we use the cookies please see our cookies policy.

Plot No. 2C, KIADB Industrial Area, Phase III, Obadenahalli, Doddaballapura, Bengaluru-561203, Karnataka, IndiaPhone : +91 80 22044620E-mail : marketing@yg1india.com

Sharjah Airport International Free Zone Building X2, Offices 28/29 Warehouse A2-035P.O. Box: 124481 Sharjah United Arab EmiratesPhone : +971 0 6 522 1419E-mail : CSR@yg1me.ae

Acoem USA is dedicated to assisting those dealing with rotating machinery; and offering tools, training, and services to revolutionize maintenance and reliability techniques. Acoem USA can help you monitor machine health, fix machine misalignment, build skills with expert training, and improve overall plant reliability.

0086-813-8127573

0086-813-8127573