Count Line - count on tools

I recently had your company do some reconditioning work on quite a few end mills and related items. So far, I am very pleased with the quality surface finishes I am getting on the wide variety of parts I manufacture. I will gladly have RTS do more reconditioning work for me as the need arises.

The cutters arrived yesterday and they look like jewelry. I just finished using them and they worked flawlessly. I have not pressure tested a manifold pump in the cavity just yet but I do not expect any issues.

RTS has proven to be a first choice supplier when it comes to the cavity reamers and drills, as well as the custom group drills. The custom ground drill that RTS did for us, the still work flawlessly.

The Magnum Super Premium drills will substantially outperform cobalt drills in work hardening stainless steel applications. This performance advantage is the result of construction differences between the two types of drills. Cobalt drills, manufactured to Type J NAS907 specs, has a very thick web. This web is necessary to limit breakage of the brittle cobalt steel. Magnum Super Premium drills are made of special Hi-moly tool steel, which is much tougher than cobalt steel. The web on a Magnum Super Premium drill can be thinned considerably due to the toughness of the steel.A Magnum Super Premium drill with its thin web will penetrate the work hardening stainless fast enough to continually cut beneath the chip which is hardening from deformation. This means the drill is cutting softer steel. The cobalt drill, with its thick web, cannot be fed at a fast enough rate to cut beneath the area which is hardening. As a result the cobalt drill is continually drilling into hardened steel.

I just wanted to give you a little feedback on the Tapered Reamer you guys fabricated for us. It worked perfectly. Although we don’t usually have a high demand for custom made tooling, we do occasionally require it. I will definitely be contacting you again in the future with any similar needs!

Our origins began in the automotive industry, but with a focus on continued diversification we have expanded to cover many industrial markets. Learn More

We would like to thank you for your outstanding service. The tool arrived and we are waiting for our machining expert to check it. Thank you and best regards

Our custom "blue print" cutting tools are manufactured from high speed steel or carbide that is the finest material available from select American suppliers. Learn More

With over 80 years of experience helping customers to solve their cutting tool problems you can be sure we will have a solution for you. Learn More

Rodger, We received the tooling yesterday and we're impressed with the attention to detail as well as the quick turnaround. Thank you and your team.

We tested the form tools and they ran great at your parameters. Didn't make a peep and the surface finish is as good as our other tools . . . FYI, these speeds/feeds are about 15X faster than our old tools!

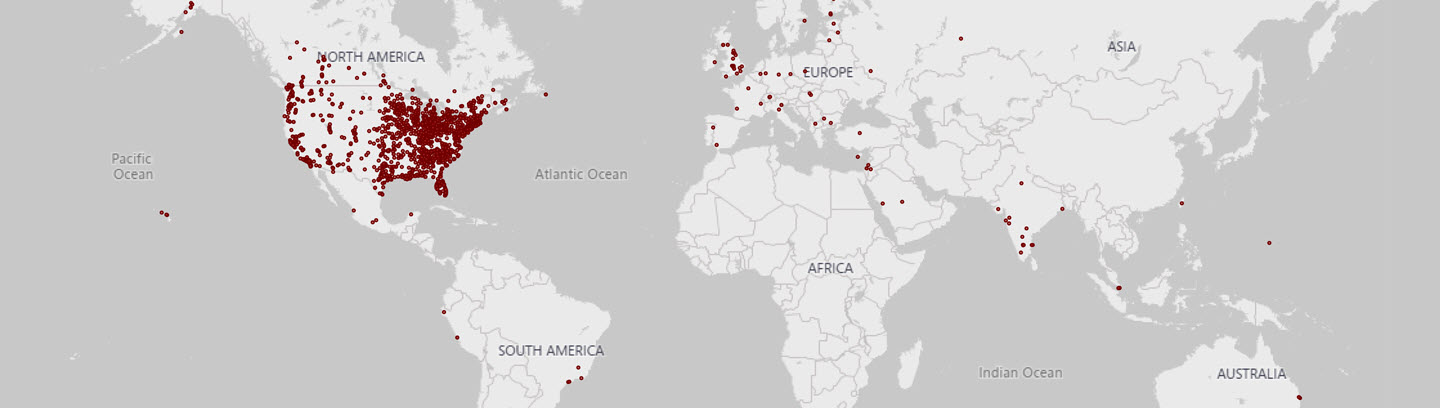

When you’ve worked in the special tools business for over 80 years –and won as many awards and certificates as we have – you’ve got to believe we’re doing something right. Our clients think so, too. RTS serves all of the major automotive, aerospace, appliance and aftermarket manufacturers in North America. Tier I, Tier II, and commodity managers are among our most valued customers.

0086-813-8127573

0086-813-8127573