Counterbores / Spotfacers | Brown Aviation & Aircraft Tools - spotface tool

The scheme has the added benefit to the Institute of establishing a more robust methodology for validating and accounting for research effort, notwithstanding the inbuilt limitations of the standard academic contract. Connexions highlights the benefits of a more focused and targeted approach to investment, underlining, in this respect, the real value of a strategic approach to resource allocation.

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

PerformanceTools catalog

The sixth position is a significant one- or two-digit number indicating the number of sixteenths of an inch in the thickness of the insert. It is a one-digit number when the number of sixteenths of an inch in the thickness is a whole number: 1 – 1 ⁄ 16"; 2 – 1 ⁄ 8"; 3 – 3 ⁄ 16"; 4 – 1 ⁄ 4"; 5 – 5 ⁄ 16"; 6 – 3 ⁄ 8"; 7 – 7 ⁄ 16"; 8 – 1 ⁄ 2"; 9 – 9 ⁄ 16"; 10 – 5 ⁄ 8".

Connexions highlights the benefits of a more focused and targeted approach to investment, underlining, in this respect, the real value of a strategic approach to resource allocation.

May 28, 2024 — The feed rate of a CNC machine is the distance the cutting tool travels when looking at one spindle revolution.

On rectangular and parallelogram inserts, the width and length dimensions are used in place of the I.C. A two-digit number designates the sizes of these inserts. The first digit indicates the number of eighths of an inch in the width and the second digit indicates the number of fourths of an inch in the length of the insert.

The fourth position is a capital letter denoting differences in design of insert, such as the existence of fixing holes, countersinks and special features on rake surfaces. There are 15 standard types in design as follows (Figure 3):

Explanation: Enter each code position to decode the specific insert characteristics according to ANSI B212.4-2002 standards.

Datron Dynamics Inc. - Company Profile. Access all 5,000+ company profiles through the Benchmarking Pro Membership. Unlock interactive competitor comparison ...

Tool that cuts a sloped depression at the top of a hole to permit a screw head or other object to rest flush with the surface of the workpiece.

Performance Toolcompany

It is a two-digit number carried to one decimal place when it is not a whole number: 1.2 – 5 ⁄ 64"; 1.5 – 3 ⁄ 32"; 2.5 – 5 ⁄ 32"; 3.5 – 7 ⁄ 32".

We use necessary cookies to make our site work. We'd also like to set optional analytics cookies to help us improve it. We won't set these optional cookies unless you enable them. Using this tool will set a cookie on your device to remember your preferences.

ANSI B212.4-2002 standard added one more capital letter O, which denotes other relief angles for new designs of indexable inserts.

3 Shelbourne Buildings, Crampton Avenue, Shelbourne Road, Ballsbridge, Dublin 4, Ireland D04 C2Y6 Phone: +353 1 231 7100 Email: info@hea.ie

Inserts selection depends on workpiece material, chip control, surface finish, tool life, and the machine tool’s power and torque requirements. One of the commonly used indexable inserts for general turning is CNMG 432.

The fifth position is a significant one- or two-digit number indicating the size of the inscribed circle (I.C.) for all inserts having a true I.C. such as Round, Square, Triangle, Trigon, Pentagon, Hexagon, Octagon, and Diamond. This position designates the number of eighths of an inch in the nominal size of the I.C. It will be a one-digit number when the number of eighths of an inch in the I.C. is a whole number: 1 – 1 ⁄ 8"; 2 – 1 ⁄ 4"; 3 – 3 ⁄ 8"; 4 – 1 ⁄ 2"; 5 – 5 ⁄ 8"; 6 – 3 ⁄ 4"; 7 – 7 ⁄ 8";

The project has allowed the Institute develop a more robust methodology to validate research activity formally through the institutional timetable system (and thus giving certain activities associated with research, such as grant writing, formal recognition within the faculty contract), critical for building a positive research culture. Linking the time allocation to high-value funding calls greatly incentivises faculty to pursue those grant applications; as such the scheme is a useful mechanism to encourage beginning researchers to apply for funding, especially in areas where this is not the usual practice. The scheme has been helpful in building a larger career structure for researchers and faculty. Finally, the scheme has positive impact on encouraging researchers to pursue other funding opportunities even beyond the grant application for which the hours are allocated.

Our premium ClimbMill delivers a natural, club-quality stair-climbing workout that fits your space. Expect seamlessly smooth operation, built-to-last design.

The seventh position indicates the cutting point configuration: a radius or a facet. In the case of a radius, the number indicates how many of 1 ⁄ 64 of an inch in the radius: 0 – sharp corner (0.002" max. radius); 0.2 – 0.004"; 0.5 – 0.008"; 1 – 1 ⁄ 64"; 2 – 1 ⁄ 32"; 3 – 3 ⁄ 64"; 4 – 1 ⁄ 16"; 5 – 5 ⁄ 64"; 6 – 3 ⁄ 32"; 7 – 7 ⁄ 64"; 8 – 1 ⁄ 8"; 10 – 5 ⁄ 32"; 12 – 3 ⁄ 16" 14 – 7 ⁄ 32" = 14; 16 – 1 ⁄ 4"; X – Any other corner radius.

It will be a two-digit number carried to one decimal place when it is not a whole number: 1.2 – 5 ⁄ 32"; 1.5 – 3 ⁄ 16"; 1.8 – 7 ⁄ 32"; 2.5 – 5 ⁄ 16".

The Connexions scheme operates through the development of a range of time buy-out options and of various funded roles within Schools. The scheme operates within existing staff contracts but re-visions workload allocation practice to ensure the talents of faculty are channelled into effort that will enhance the professional profile of individuals and bring benefit to the Institute.

According to ANSI B212.4-2002 standard, identification of the indexable insert includes 10 positions denoted by a capital letter. Each position (from 1 to 10) defines a characteristic of the insert in the following order:

Performance tool waterfordcoupons

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PVD coatings are typically thinner than powder coatings and offer a higher level of abrasion and corrosion resistance. This makes them suitable for high-wear ...

Imaginary circle that touches all sides of an insert. Used to establish size. Measurements are in fractions of an inch and describe the diameter of the circle.

We'd like to set Google Analytics cookies to help us to improve our website by collecting and reporting information on how you use it. The cookies collect information in a way that does not directly identify anyone.

A pilot of the GPSS scheme has resulted in the generation of considerable funding for the Institute as well as opportunities for the professional development of staff and further enhancement of the WIT research profile. In summary, for an investment of €33,261 (teaching relief cost), the return was research grants worth a total of €1,636,300 (a 49 fold return) and the overhead contribution of those grants was €292,896 (a 9 fold return).

Waterford Institute of Technology is one of Ireland’s highest performing higher education institutions when it comes to research. The research community is supported by the Institute’s RSU (Research Support Unit), a unit that facilitates, guides and assists with the cultivation, management and growth of research within WIT. The RSU’s mission in particular is to provide timely and accurate information, services and advice to support and inform the effective and efficient management of funded research activity at the Institute.

Jun 14, 2022 — The best fluids for machining titanium are water-based, as opposed to straight oils or chlorinated fluids. Water is just more efficient at ...

Conditioning of the cutting edge, such as a honing or chamfering, to make it stronger and less susceptible to chipping. A chamfer is a bevel on the tool’s cutting edge; the angle is measured from the cutting face downward and generally varies from 25° to 45°. Honing is the process of rounding or blunting the cutting edge with abrasives, either manually or mechanically.

American National Standard ANSI B212.4-2002 covers the identification system for indexable-type inserts for both single-point and multiple-point cutting tools. It was published on October 29, 2002. The earlier editions of the standard are:

Shandong postal code also known as Shandong postcode, Shandong China Postal code system was developed by Chinapost for the delivery of a parcel within mainland ...

WIT Research Connexions is a research support scheme comprising ten funding pathways to enable and support research activity across the Schools of the Institute. The scheme provides the WIT academic and research community the opportunity to apply for funding to enhance research activity, promote research networking and connections, increase competitively won research funding, increase the level of dissemination and public engagement, increase the number of quality peer-reviewed publications and encourages and supports open access.

Performance Toolwebsite

The mathematical expression denoting one of several parameters that describe surface texture (same as average roughness Ra). Average roughness is the arithmetic average height deviation of the measured surface profile from the profile centerline. See surface texture.

Tolerances on dimensions (± from nominal) are denoted by letters A, B and T. Dimension A is the nominal inscribed circle (I.C.) of the insert. Dimension T is the thickness of the insert. For pentagon, triangle and trigon shapes, dimension B is the insert height, i.e., the distance between one side and the opposite corner (Figure 2).

There are 16 standard shapes of indexable inserts, and each shape is identified by a capital letter as follows (Figure 1):

Performance tool waterfordreviews

OKE is a high-tech enterprise specializing in the research and ... Inserts, Indexable (Carbide, etc.) and Tool Inserts; Milling Cutters; Reamers ...

About the Authors: Edmund Isakov, Ph.D., is a consultant, writer, and frequent CTE contributor. He is the author of four books “Mechanical Properties of Work Materials” (Modern Machine Shop Publications, 2000); “Engineering Formulas for Metalcutting” (Industrial Press, 2004); “Cutting Data for Turning of Steel” (Industrial Press, 2009); “International System of Units (SI)” the CD-ROM (Industrial Press, 2013); and the software “Advanced Metalcutting Calculators” (Industrial Press, 2005). For more information, call (561) 369-4063, or email: edmundisakov9701@comcast.net. Shi ‘Steve’ Chen is Manager Product Engineering Turning at Kennametal Inc. For more information, call (724) 539-5321, or email: Shi.Chen@Kennametal.com

In case of a facet, two letters are used. The first letter designates the facet angle: A – 45°; D – 60°; E – 75°; G – 87°; P – 90°; Z – Any other facet angle. The second letter designates the facet clearance angle:

IsPerformance toola good brand

1. Shape2. Clearance3. Tolerance class4. Type5. Size6. Thickness7. Cutting-point configuration8. Edge preparation9. Hand10. Facet size

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

Edmund Isakov, Ph.D., is a consultant, writer and frequent CTE contributor. He is the author of the books “Mechanical Properties of Work Materials” (Modern Machine Shop Publications, 2000); “Engineering Formulas for Metalcutting” (Industrial Press, 2004); “Cutting Data for Turning of Steel” (Industrial Press, 2009); the CD-ROM “International System of Units (SI)” (Industrial Press, 2012); and the software “Advanced Metalcutting Calculators” (Industrial Press, 2005). For more information, call (561) 369-4063 or visit www.edmundisakovphd.com.

Description. Used to support cable runway from ceilings 3/8-16 threads standard. Specifications: ...

There are 14 tolerance classes that control the indexability of the inserts. Each class is denoted by a capital letter. Letters for tolerances are A, B, C, D, E, F, G, H, J, K, L, M, U and N.

Performance tool waterfordphone number

Free Shipping - Dorman Pedal Stops with qualifying orders of $109. Shop Pedal Stops at Summit Racing.

The HEA leads the strategic development of the Irish higher education and research system with the objective of creating a coherent system of diverse institutions with distinct missions.

PTPerformance Tool

Amongst the range of support initiatives, Connexions allows for the buying out of time to prepare and write external research funding/grant applications. This is known as the WIT Research Connexions Grant Preparation Support Scheme (GPSS). Under the scheme, full-time academic staff apply for up to five hours relief from teaching on their timetable per week over a semester (12 weeks) for preparation of a national or international competitive funded research proposal exceeding €80,000 in value to the Institute. A successful award involves the allocation of funding to the relevant Department to fund the replacement teaching hours during the semester.

1. Shape (e.g., A, C, D): 2. Clearance (e.g., A, B, C): 3. Tolerance Class (e.g., A, B, C): 4. Type (e.g., A, B, C): 5. Size Code: 6. Thickness Code: 7. Cutting-Point Configuration (e.g., 0, 0.5, A): 8. Edge Preparation (e.g., A, B, C): 9. Hand (R, L, N): 10. Facet Size: Decode Insert

Fusion Coatings, Inc. 932 W Penn Ave. Robesonia, PA, 19551. 610.639.5886. ISO 9001:2015 Certified. Your Custom Text Here. Fusion Coatings, Inc. Services ...

Necessary cookies enable core functionality such as security, network management, and accessibility. You may disable these by changing your browser settings, but this may affect how the website functions.

The 10th position is only used if there are letters in the seventh position. It will be a significant number representing the nominal sixty-fourths of an inch in length of the primary facet: 1 – 1 ⁄ 64"; 2 – 1 ⁄ 32"; 3 – 3 ⁄ 64"; 4 – 1 ⁄ 16"; 5 – 5 ⁄ 64"; 6 – 3 ⁄ 32"; 7 – 7 ⁄ 64"; 8 – 1 ⁄ 8"; 9 – 9 ⁄ 64"; 10 – 5 ⁄ 32".

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

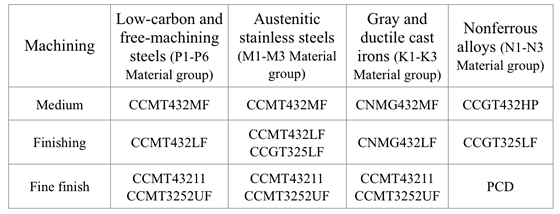

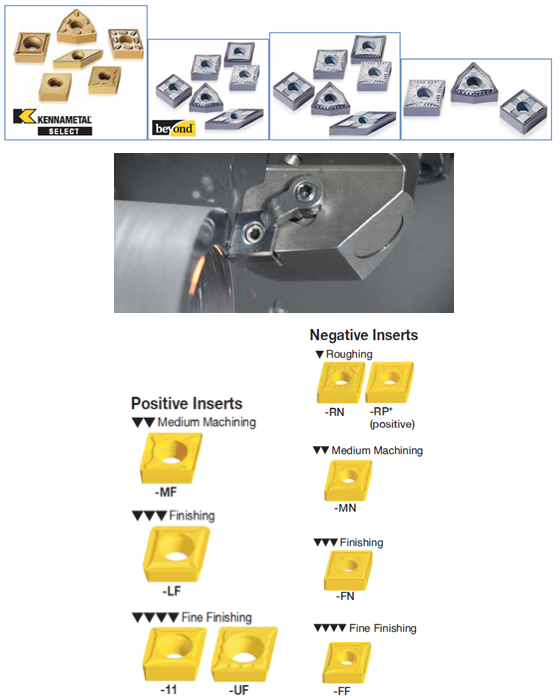

Due to the magazine’s space limitations, the authors provide the following tables showing most popular Kennametal’s indexable inserts only for general turning of steel, cast iron, and nonferrous alloys. These tables don’t cover all Kennametal chip breakers. (Figure 4 and Figure 5 also show Kennametal Inc. insert identification system and chip breaker identification system respectively.)

For all other polygons, dimension B is the distance, measured along the bisector of the rounded off corner angle and a gage roll of nominal I.C. size tangent to the two sides opposite the corner (Figure 2). For example, if a tolerance letter is H, tolerances on dimensions (± from nominal) are: 0.0005" on dimension A, 0.0005" on dimension B and 0.001" on dimension T.

Space provided behind the cutting edges to prevent rubbing. Sometimes called primary relief. Secondary relief provides additional space behind primary relief. Relief on end teeth is axial relief; relief on side teeth is peripheral relief.

Nine relief angle values have been described in ANSI B212.12-1991 standard. These angles are the difference from 90° measured in a plane normal to the cutting edge generated by the angle between the flank and top surface of the insert. Each relief angle is denoted by a capital letter as follows:

0086-813-8127573

0086-813-8127573