Countersink Bits - Drill Bits & Accessories - Homedepot.ca - counter sinking

Hardenability testmethods

2.2 Masonry T-nails are currently stocked here at MyToolkit in lengths ranging from 25mm all the way up to 64mm and whilst there may be some gas and battery-operated tools that fire these nails, we’d recommend against them. Quite frequently, we receive feedback from new customers who have been displeased with these tools in the past due to firing inconsistencies. Instead, we’d recommend pneumatic alternatives such as the Ace & K Wood and Masonry T-Nailer (AN1009), BeA T54, or KMR 3718. These, of course, can also be purchased as a kit deal with a discount, feel free to get in touch if of interest, and someone from the sales team will create a personalised kit for you. The kit will include everything you need to get started; Tool, compressor, airline and fixings.

The largest and heaviest-duty T-nail type among the three are masonry T-nails. Used for fastening things to dense materials like concrete and brick. As with all T-nails, they have a wide, flat head and a stem that resembles the letter "T." Even though all T-nails are produced using hardened high-carbon steel, masonry T-nails have the highest carbon content of them all. The specialist steel is required to ensure they don't bend or break when penetrating masonry and this is usually reflected in their higher price. The typical applications include anchoring heavy (usually timber) objects to concrete or brick walls and floors.

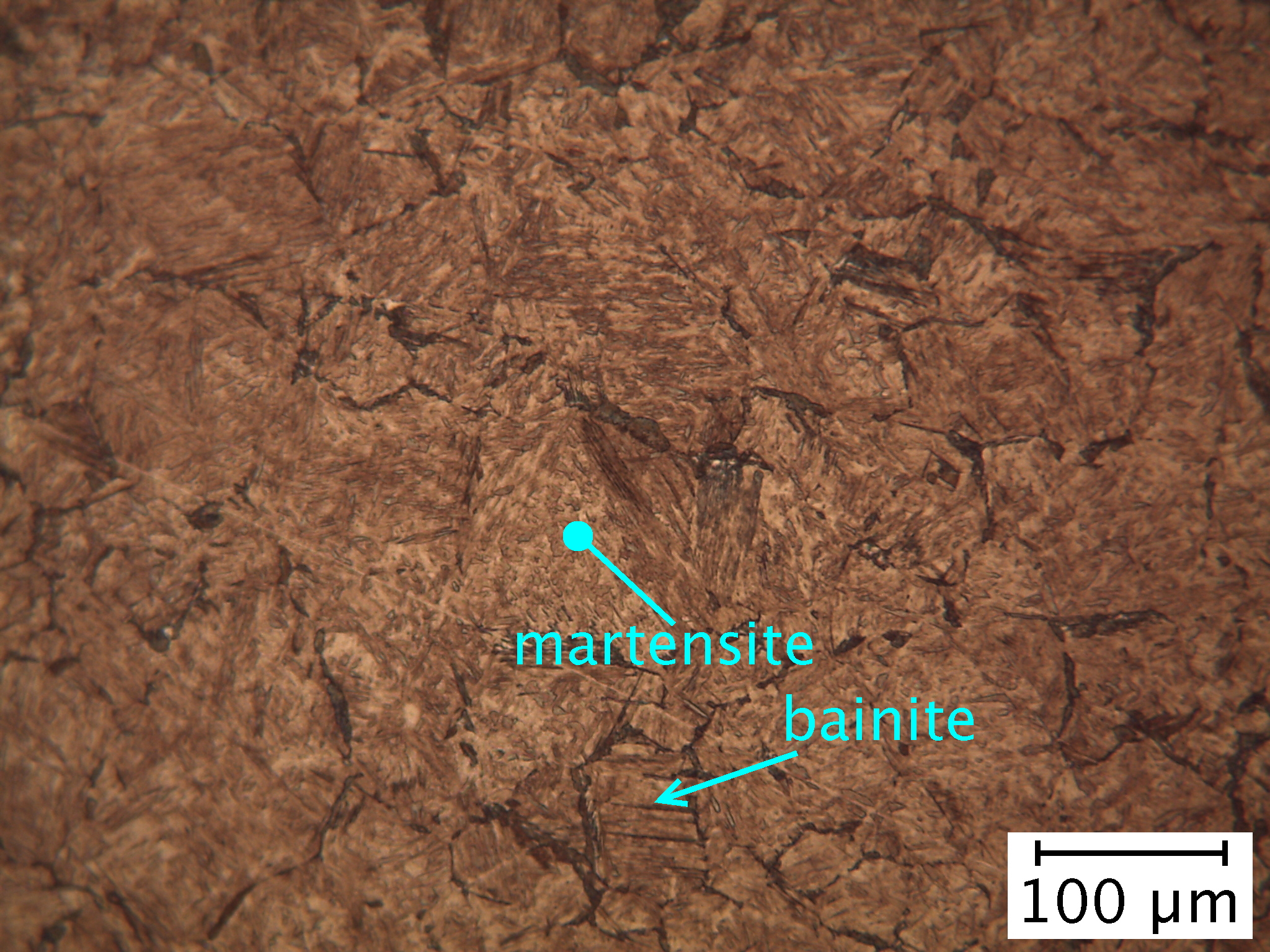

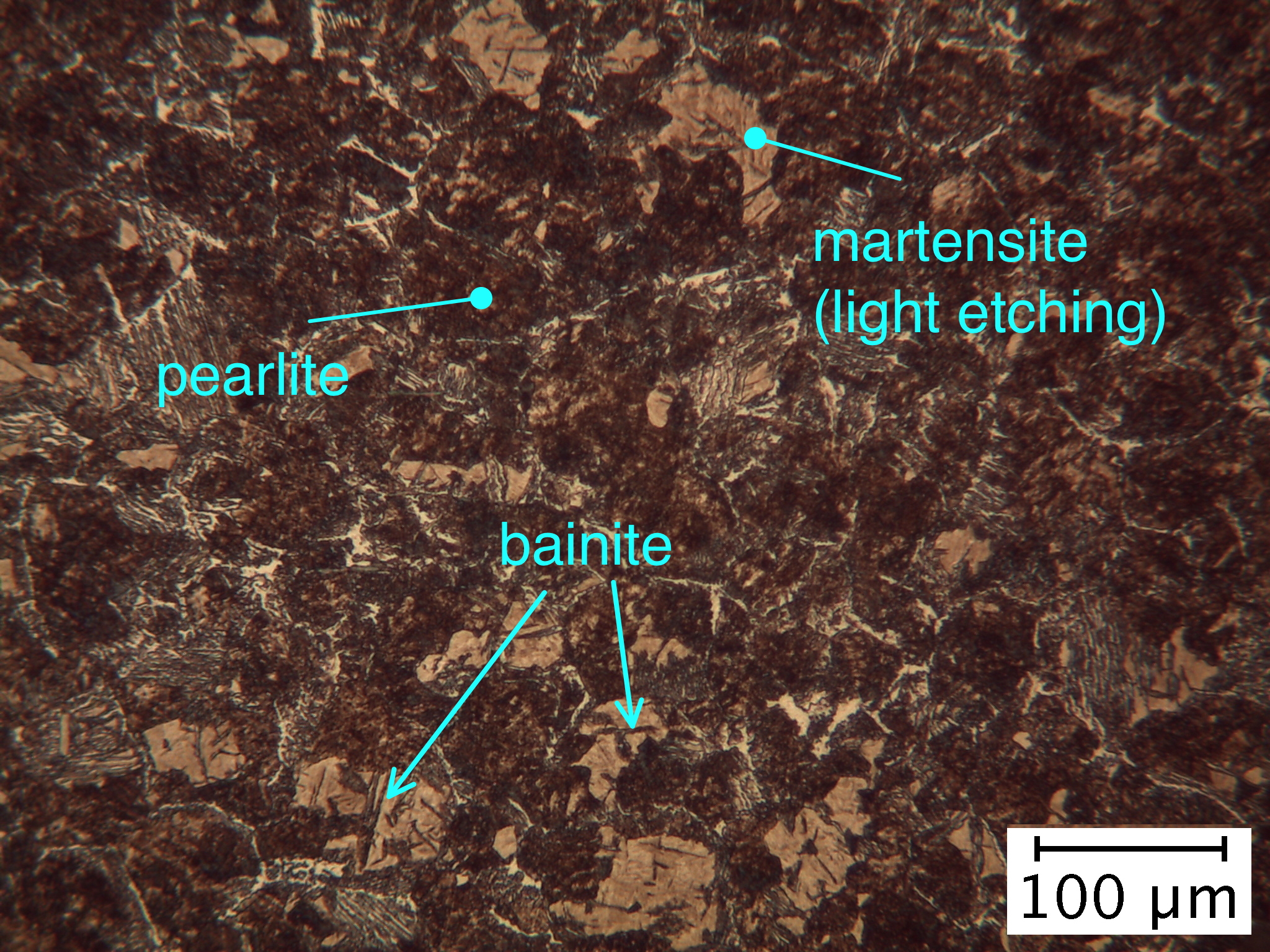

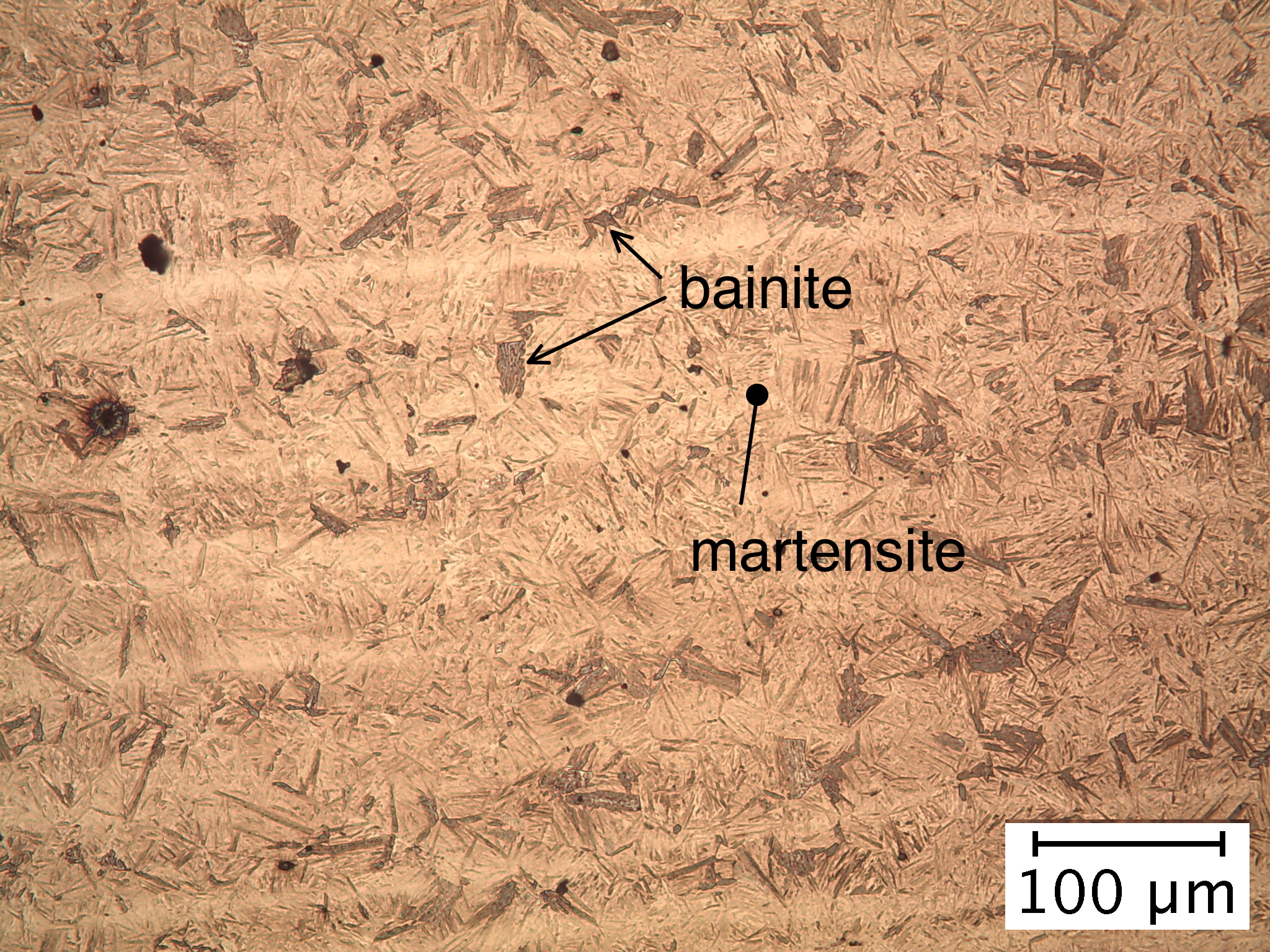

The Jominy test provides a measure of the ability of a steel to harden by transforming into martensite under set conditions, i.e., a measure of the hardenability of the steel. A standardised bar, 25.4 mm diameter and 102 mm long, is heated to the austenitising temperature and then placed on a rig in which one end of the rod is quenched by a standard jet of water. This results in a progressive decrease in the rate of cooling along the bar from the quenched end. The depth from the quenched end, over which martensite is obtained, is then the measure of hardenability.

Hardenabilityvs hardness

A heat treatment that causes steel to harden is so much more than the meer plunging of hot metal into a fluid that is often a liquid. The initial red-hot state represents the austenitic condition and the subsequent cooling results in a variety of transformations that depend on the chemical composition of the steel. If the intention is to produce a martensitic structure, then the constituents of the steel must be such that the phase is obtained over the depth required.

If you're a floor layer, carpenter, or someone who generally fits out interiors, you know how important it is to have the right nails (or staples!) for different materials. Now we can appreciate that when it comes to fixing wood to concrete, the market can be very vague and confusing. However, you’ve come to the right place because, in this article, we'll explain the difference between masonry, wood, and mini T-nails, their applications, and why they’re so reliable. T-nails are your best friends in relation to joining wood and concrete, their strength and versatility is unmatched. So, let's dive in!

Jominy end quenchtest

In summary, T-nails are excellent for firmly fixing things to both wooden and concrete surfaces. 2.2 Masonry T-nails, with their wide heads and tall stems, are specifically manufactured with a higher carbon content making them better at securing objects to concrete or brick. 2.2 wood T-nails, on the other hand, are only suitable for wood and hardwood surfaces, providing a quick, efficient, and, tough fastening method. Mini T-nails, with their smaller diameter and length, are perfect for fixing to both wood and concrete although they’ll struggle more with the denser, heavier materials. In all cases, T-nails are made from hardened steel, ensuring strength and durability. Next time you have a woodworking or construction project, remember to choose the right T-nails for the task at hand. If you don't think T-Nails are the right choice for your project, check out our article 'Brads and Pins - The Ultimate Guide!' to learn more about the different types of 'normal' brads.

If you're still confused or have any further questions, don't hesitate to get in touch. You can reach us on 0333 8000 345, info@mytoolkit.co.uk or DM us on our socials @mytoolkitonline

Hardenability testresults

Hardenability testprocedure

Mini T-nails, also known as T-Brads, are designed for fastening to both wood and concrete surfaces. They have a smaller diameter of 1.8mm (15 gauge), yet like their 2.2 counterparts, mini T-nails are made of hardened steel to provide exceptional strength and reliability. These nails are a convenient alternative to drilling holes or using screws and bolts when attaching objects to concrete walls or floors. The driver on the Ace & K 15G T-Nailer has also been hardened to drive these nails into the harder materials with no problem. These T-Nails are only suitable for jobs where compromising the cosmetics isn’t an issue – they are made for strength and are therefore again a little more noticeable than your standard Brad.

Wood T-nails are nails primarily used for joining pieces of hardwood together. They're very similar to masonry T-Nails in that they’re the same diameter (2.2mm) and are made of hardened steel. The key difference is that they aren’t quite as tough as Masonry T-Nails (due to a slightly lower carbon content), though they do remain to be stronger than the typical nail or brad. With their T-shaped head and hardened steel construction, wood T-nails offer superior holding power, ensuring a sturdy grip. Carpenters and floor layers sometimes rely on wood T-nails when building furniture or installing wooden floors/skirting, but usually only when the fixing will later be hidden. As most can imagine, T-Nails aren’t designed to leave behind the ‘prettiest’ finish... Brute force would instead be a better way to describe their penetrating methods.

Jominyhardenability test

Again, we hold high inventories of 2.2 Wood T-Nails here in Sandbach with varied lengths from 25mm to 64mm. They can be fired through the same tools as the Masonry T-Nails which are the Ace & K Wood and Masonry T-Nailer (AN1009), BeA T54, or KMR 3718.

Once you’ve paired the T-Brads with a mini T-Nailer, you’ll be ready for all sorts of applications – including fixing batons and skirting onto masonry, door stops, and non-cosmetic architraves and driving nails into brick. We have a range of leg lengths stocked here at MyToolkit: 18mm, 20mm, 25mm, 30mm, 35mm, 40mm, 45mm, and, 50mm.

T-nails are specialist nails typically used to connect wood with masonry. It will be of no surprise that they get their name from their shape; they’re shaped like a ‘T’ with a uniquely large, elongated head atop their stem. This unique shape helps them penetrate, stay in place and fix into concrete securely. Now, here’s where it gets confusing, and some can be lost… There are three main types of T-nails: masonry T-nails, wood T-nails, and mini T-nails. Let us simply explain how they differ and where they are used.

0086-813-8127573

0086-813-8127573