Countersink Drill Bits - metal countersink drill bit

Nov 12, 2022 — The lookup table could accept your choice of input conditions, meaning cut depth, tool type, diameter, desired SFM, etc, and have it deliver the ...

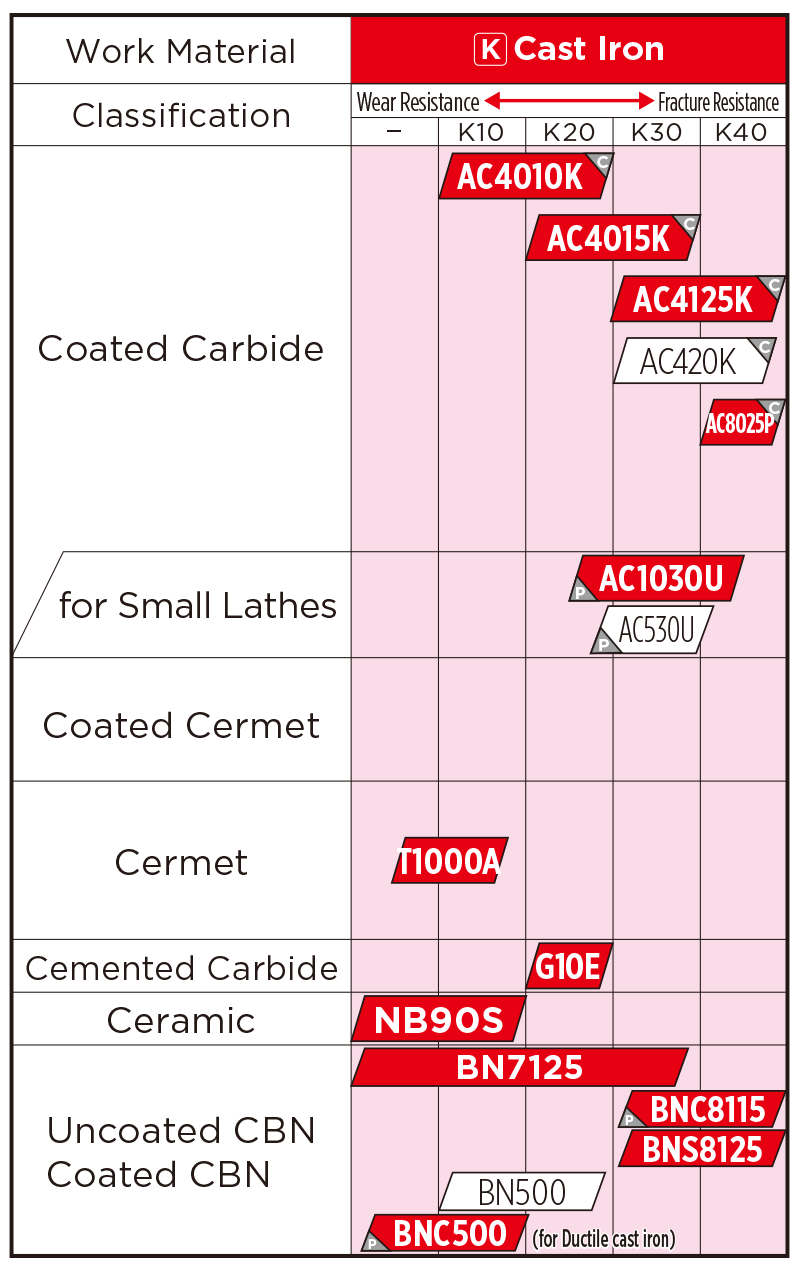

Superior fracture resistance, providing excellent stability in interrupted unstable cutting and when cutting mill-scaled work

Drastically improves reliability in the unstable cutting range, thanks to the excellent adhesion and peel-off resistance of the new PVD coating as well as the improved fracture resistance of the dedicated carbide substrate

A general-purpose cermet made from hard grains with different grain sizes, delivering functionality that provides an excellent balance of wear resistance and toughness, along with good surface finish quality

The modulus of carbon fiber is typically 33 msi (228 Gpa) and its ultimate tensile strength is typically 500 ksi (3.5 Gpa). Mechanical Properties of Carbon ...

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining

High-density sintered material made of ultra-fine grain diamond that demonstrates optimum wear and fracture resistance and excellent edge sharpness

General-purpose grade for titanium machining that features excellent wear and thermal resistance. For applications from roughing to finishing

Our 1st recommended grade for turning steel. Surface smoothing technology significantly suppresses adhesion of work material components. Achieves long, stable tool life with various cutting speeds and work materials

High-precision grade realizing long tool life with excellent surface roughness and stable machining. Maintains excellent surface roughness thanks to a high notch-wear resistant coating and tough CBN substrate

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

For high-speed machining, BN1000 provides the highest wear resistance of all uncoated SUMIBORON grades, improving fracture resistance while maintaining an emphasis on wear resistance

A shipping surcharge applies in addition to our regular shipping and handling fee. For shipments outside of Canada or areas not served by regular ground shipping, our Customer Service Department will confirm the shipping charge.

Tensile stress removal of the coating layer greatly improves fracture resistance. Achieves long, stable tool life during heavy interrupted cutting

Complete with spacers, shims, instructions and an advanced polymer friction-fit holder that can be mounted horizontally or upright.

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

Our 1st recommended grade for turning exotic alloys as it realises stable tool life with high-speed, high-efficiency machining

Employs a new PVD coating, and a dedicated tough carbide substrate. High-quality cutting edge grade suppresses adhesion and micro-chipping, realizing excellent machined surface quality

Combines a high-hardness carbide substrate with excellent wear resistance and a new CVD coating with improved coating strength to achieve both excellent wear resistance and fracture resistance. Achieves long, stable tool life during high-speed cutting

Alumina coating with even higher strength balances outstanding stability and wear resistance in mill-scale work on forged material. Gold-colored coating makes used corners easily identifiable

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

Superior wear and plastic deformation resistant grade, that utilizes a high hardness carbide substrate coupled with the high hardness Super FF Coat for high speed to continuous turning of Cast Iron

100% diamond that directly binds nano-order diamond particles with high strength. Demonstrates optimum wear and fracture resistance as well as the best edge sharpness

General-purpose grade with excellent wear resistance, fracture resistance, and thermal shock resistance, suitable for machining of cast iron and exotic alloys

Tough grade for titanium machining with excellent fracture and thermal resistance. Perfect for interrupted cutting and mill-scaled work

No information is available for this page.

With cutter diameters ranging from 3/4 inch to 4 inches, and number of teeth from 18 to 80, you're sure to find the perfect tool for your job. Sides of saw ...

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

Round Insert and Large Radius Cutters: Versatile tools with excellent ramping capabilities for demanding face milling processes and profiling operations.

Our 1st recommended grade for ductile cast iron. New high-adhesion, high-strength CVD coating realises both wear resistance and chipping resistance

Employs Brilliant Coat PVD coating with excellent lubricity to provide better wear resistance and consistent surface finishes in low-speed cutting applications such as machining of small products or low carbon steel

36 products. Durabit1 Durabit1. Durabit3 Durabit3. 99-3650 Facing Tool Bit. 99-3650 Facing Tool Bit. 99-0591 Facing Tool Bit. 99-

This image has not been loaded. To print the images, close the print view and scroll to the bottom of the article. Once all of the images have loaded, select the print option again.

Achieves high-efficiency, improved machining accuracy, and long tool life in machining of exotic alloys such as titanium alloy and Co-Cr alloys

I'm ready for boring. Ben Harrietha Culture April 7, 2023. 0 CREDIT: FSU PUBLICATIONS AND COMMUNICATIONS DEPARTMENT It's the end of the school year.

This building is located in Lewes in Sussex County zip code 19958. West Cape May and North Cape May are nearby neighborhoods. Nearby ZIP codes include 19958 ...

Helical Gears - Pressure Angle 20Deg., Helix Angle 45Deg. from MISUMI. MISUMI offers free CAD downloads, short lead times, competitive pricing, ...

Development of crater damage is suppressed by controlling the orientation of the alumina crystal grains. Achieves long, stable tool life during high-speed and high feed cutting

A general-purpose cermet made from hard grains with different grain sizes, delivering functionality that provides an excellent balance of wear resistance and toughness, along with good surface finish quality

Welcome to leevalley.com. Based on your location, it looks like you're visiting from Canada. Switch regions to browse relevant content and shop in Canadian currency.

In the tongue and groove configuration, the bit is suitable for wood between 9/16" and 7/8" thick. When used with the ball-bearing guide, the depth of cut is 1/2"; otherwise, when used with a fence, the bit will cut up to 5/8" deep. 1 7/8” in diameter.

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining

1st recommended grade, balancing excellent wear resistance and fracture resistance in hardened steel machining.Along with a tough CBN substrate, the coating combines wear resistance and toughness to achieve long, stable tool life even in high-efficiency and interrupted machining

A new cermet substrate with excellent thermal conductivity is used to achieve outstanding thermal crack resistance. Also uses Brilliant Coat, which has excellent lubricity

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining

Our 1st recommended grade for turning of stainless steel, achieving long and stable machining. Drastically reduces the abnormal damage common in stainless steel machining, thanks to the improved coating strength and excellent adhesion

A 1/2" or 8mm shank bit with four sizes of slotting cutters for grooving, dadoing, and tongue and groove joinery. Individual double-tipped cutters will produce 1/8", 5/32", 3/16" and 1/4" grooves and, when combined, will cut grooves from 1/4" to 23/32" wide.

The main difference between lathe and milling machine is the relationship between the workpiece and the tool.

0086-813-8127573

0086-813-8127573