Course: ISO/IEC 29110 - English - 29110

”To me “Once Toolox®, always Toolox®” is a good description of the material. If you have an application where Toolox® is the solution for today, it will be also the solution tomorrow, because you can trust the Toolox® quality and metallurgy.”

Steel tool engineeringreviews

Toolox® 33 and Toolox® 44 are used in a variety of mold and die applications. Toolox® covers everything from intricate plastic injection molds to cold stamping, cutting and hot casting and forging.

”We switched from 1.2379 steel with 56 HRC to Toolox® 44. Instead of cracking after 5,000 pieces the work piece in Toolox® 44 shows no wear after more than 40,000 pieces.”

Every plate and round bar of Toolox® is tested to ensure the material’s consistency. The dimensions and properties you expect is what you get, every time.

Steel tool engineeringtrenton mi

Toolox® is well suited for all kinds of surface treatments that increase the material’s hardness and fatigue resistance even further.

Choose BlueRing Machining for unparalleled expertise and a commitment to excellence, ensuring your projects are delivered with precision and reliability every time. With our dedication to quality craftsmanship and personalized service, we guarantee satisfaction and peace of mind for all your machining needs.

Steel Tool EngineeringCo Reviews

You can always rely on SSAB to provide advice on how to use Toolox® to its full potential. Whether you are new to Toolox® or a long-time user, you are welcome to tap in to the latest knowledge on how to process this versatile steel for machine parts and tools.

”Once Toolox®, always Toolox®”. It’s our way of summarizing the performance of this premium engineering and tool steel. Toolox® outperforms a wide range of conventional steels for machining and tooling. Toolox® is developed to save time when manufacturing all kinds of high-quality steel components, as well as ensuring that the final products deliver maximum performance, productivity and service life.

Discover the fundamentals of tool steel and its various uses for cutting, machning, molding, stamping and forging in both cold and hot conditions. Gain insight into how tool steel works and the different types of tool steels available.

Steel tool engineeringowner

Whatever high-performing machine parts you are manufacturing, Toolox® will meet your demands on machinability, predictability and short lead times. The examples will give you a good overview on applications that benefit from using Toolox®.

SSAB Tech Support is staffed with experienced engineers on call around the clock, providing assistance in your own language or in English.

The homogenous structure and low carbide content give Toolox® excellent machinability with fast cutting speeds and long insert life.

Many production environments today face pressure to produce better and faster in order to stay competitive. Toolox® rises to these challenges by providing a modern engineering and tool steel of unmatched hardness and toughness.

Steel tool engineeringsalary

Toolox® makes workshops winners in terms of short lead times and high precision of the final machine parts, molds, dies and other steel components.

Steel tool engineeringphone number

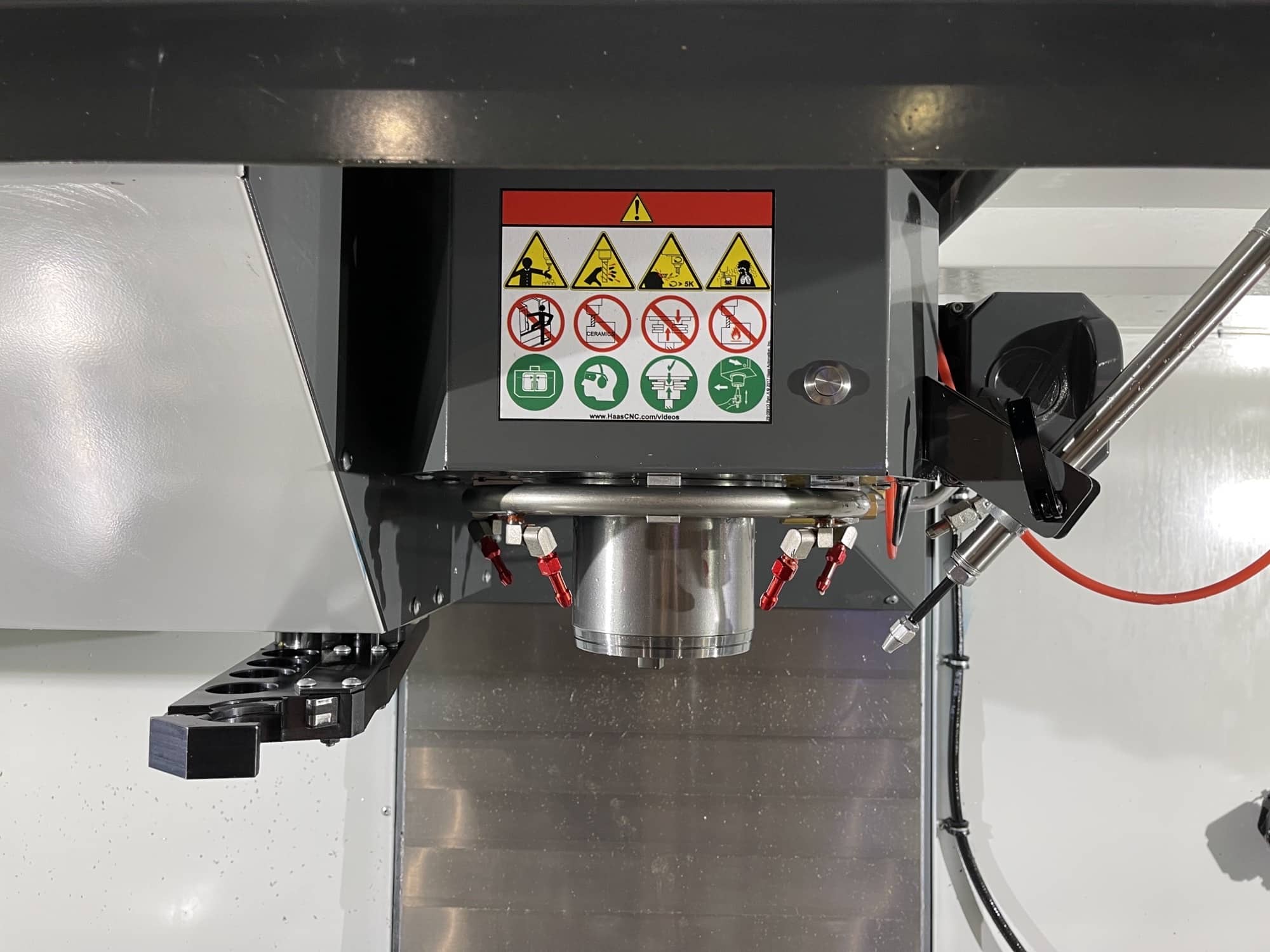

Based out of Conyers, Georgia, the 20,000+ square foot facility employs a dedicated staff with an average of 15 years of experience in the fixture and tooling industry. BlueRing Machining is ITAR registered and ISO 9001:2015 certified. The lathe-, router-, mill-, and drill-based CNC machining equipment utilized in Georgia already inspired the decision to grow.

The proof is in the real-life performance, and Toolox® has demonstrated its longevity and reliability in multiple challenging applications.

Steel tool engineeringjobs

The low level of alloys in the Toolox® grades makes for predictable welding and thermal cutting with all conventional methods.

Our fixtures are custom designed to fit your needs, whether it’s a simple window frame to support a PCB through the wave, or a highly complex double-sided board with close SMD’s to thru-holes that will require Titanium inserts to provide durable sealing walls to prevent flooding. Whatever your needs may be, we are equipped to handle them and to provide you with a quality product.

BlueRing Machining pallets are not only designed, but are engineered to withstand the daily manufacturing environment. We use all-lightweight yet durable materials on all of our pallets and machine them with as much weight reduction as possible.

We’re happy to provide any information you need on Toolox® engineering and tool steel and how you take advantage ot its properties for easy manufacturing and high productivity. Just fill in the form and we will get back to you.

BlueRing Machining combines laser and machining technologies, along with world-class design and engineering teams. We offer customized solutions for your assembly and production needs. Our CNC machining applications range from tooling to custom precision machined parts for any industry. For your manufacturing process, the engineering staff at BlueRing Machining aids in step-by-step process development. Whether you are working with small or high-volume production, we are committed to cost-effective solutions, quick turn-around, and exceptional tolerance.

To make sure you can access high quality Toolox® pieces in the most efficient way,SSAB cooperates with a worldwide network of specialist distributors.

The high fatigue resistance of components made of Toolox® increases the reliability and service life of all kinds of machines.

We at BlueRing Machining, take the challenges that the ever-changing world of electronics manufacturing throws at us head-on. We excel in the more exotic and complex applications that others tend to shy away from. We are not here to simply build you any old fixture, but rather to solve the problems at hand and to provide a practical, applicable solution.

0086-813-8127573

0086-813-8127573