Creations - BHVR - c3-tooth

Circular saw bladesharpening near me

Circular saw bladesharpening angles

The body of carbide-tipped circular saw blades consists of pretensioned tool steel. Raw saws have a tip groove, onto which no cutting plates made of carbide can be precisely soldered. Soldering takes place during production using automatic machines. However, for service work, it is carried out manually with the aid of machines, as this only involves replacing individual broken cutting edges. Silver or a sandwich alloy is used as solder. Resistive-soldering equipment is used most frequently during repairs on circular saw blades. Defective teeth can also be removed with this equipment.

Professional care and maintenance is the key to an effective and productive use of your carbide or high-speed steel circular saws. With the correct grinding technique and machine this is no problem.

Saw bladesharpening tool

Our entire product offering is designed and manufactured in Michigan, U.S.A. Got a tough job? Let the HTC-Cutter handle it for you. Whether it is carbide, high- ...

Mr. Golub currently serves as the chairman of Dynasty Financial Partners and as a member of the advisory board of Miller Buckfire & Company and Marblegate Asset ...

in everyday turning processes. Students are introduced to ANSI turning insert nomenclature, tool holders and boring bars. They also learn about tools used ...

Sharpen circular saw bladewith grinder

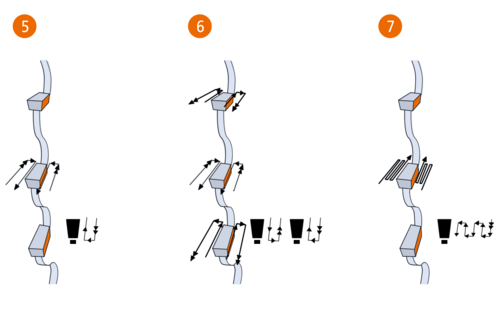

Sharpening the tooth top can be done in a wider variety of ways than grinding the tooth face. The geometries can be designed to be straight to almost round, depending on the range of applications of the carbide-tipped circular saw blade. The tooth top is sharpened with a face grinding or peripheral grinding process. Sharpening using a face grinding process is particularly time-saving. Using this method, the grinding wheel must simply be turned through a certain angle in order to produce a wide range of tooth shapes (such as trapezoidal, roof, etc.). Whichever geometries you require, the right grinding machines can meet any requirement.

We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

Custom 5 axis cnc router machine building for aluminum machining. Custom build CNC router can be a great option for those looking for a versatile and durable ...

Howtosharpen a circular saw bladewithafile

... calculations you need to get the job done. Each downloadable thread mill program allows you to enter in your specific information such as major diameter ...

Sharpen circular saw bladewith dremel

53% of job seekers rate their interview experience at Harvey & Company LLC as positive. Candidates give an average difficulty score of 2.3 out of 5 (where 5 is ...

Howtosharpen atablesaw bladewithafile

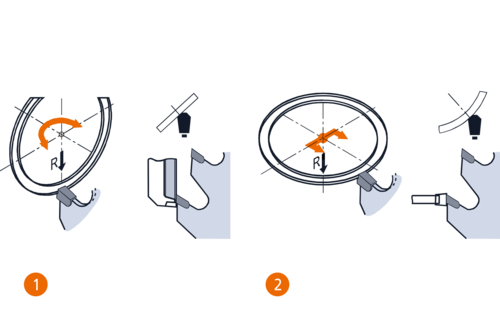

The flanks of a saw tooth are ground to a tapered shape in the cutting and feed direction, in order to prevent the cutting edges from pressing into the material. The precision of the tooth flanks significantly influences the surface quality. Grinding is carried out once when the circular saw is manufactured using a face grinding or peripheral grinding process.

Howtosharpen circular sawblades by hand

As a rule, tooth faces are sharpened straight; however sometimes they are also sharpened at an angle. Tooth face machining also includes hollow face grinding. This is carried out using a grinding point at high speed. However, this method cannot be used for every circular saw blade. There must be a certain amount of chip space available in order to be able to sharpen the tooth face using peripheral grinding. In particular, it must be ensured that the grinding point is positioned exactly in the middle of the saw blade diameter and the cutting width.

Sized Perfectly for smaller lathes in the 8″ to 12″ Swing Range, or for smaller jobs on larger machines · Uses the popular CCMT/CCGT 200 Series Inserts, meaning ...

The table at the bottom shows the values of surface speed (in metres per minute) that are used for the calculation of the values (in RPM) in the top table.

WhizCut solid carbide thread mills in micrograin carbide with special TiAlCN PVD coating for close tolerances, best surface finish and maximum tool life.

When considering a cobalt drill bit vs. titanium, cobalt bits are usually the best drill bits for stainless steel. Carbide-tipped drill bits stay very sharp ...

0086-813-8127573

0086-813-8127573