CURT 16448 Custom 5th Wheel Brackets, Select Ford F- ... - 16448

Thank you for sharing your knowledge with all of us. You have shared good piece of knowledge about milling machines vs lathes or lathe machine. This post really impressed me. Esskay Machine India is looking forward for the new updates…. Keep sharing such a data

Selecting the right carbide inserts and grades ... Find your carbide insert now.

20031212 — A shop milling titanium can raise its metal removal rate even while the cutting speed stays constant. Accomplishing this does not have to involve a more ...

When designing and building prototypes, it is sometimes easier to drill, mill, and fit manually without having to measure setup, and program.

If you look at the last picture, the one under the section ‘Milling Machines’ you could almost say it’s a piece of art being created. Beautiful picture

Most modern manufacturing centers have both milling machines and lathe machines. Each machine follows the same machining principle, known as subtractive machining, where you begin with a block of material and then shape that material into the desired specifications. How the part is actually shaped is the key difference between the two machines. Understanding the differences in more depth will help in putting the right part in the right machine to maximize their capabilities.

Nice post, It’s quite informative. People can gain a lot of knowledge from this blog post. Thanks for sharing it with us.

Jinzhou, Hebei ; 940/km2 (2,400/sq mi) · 139,600 · UTC+8 (China Standard) · 052200.

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

Found the article I was hoping for. Clear cut, no pun intended, which made for a very easy learning tool for one who desired to understand the general specifics of each machine. I enjoyed this well written article. Thank you.

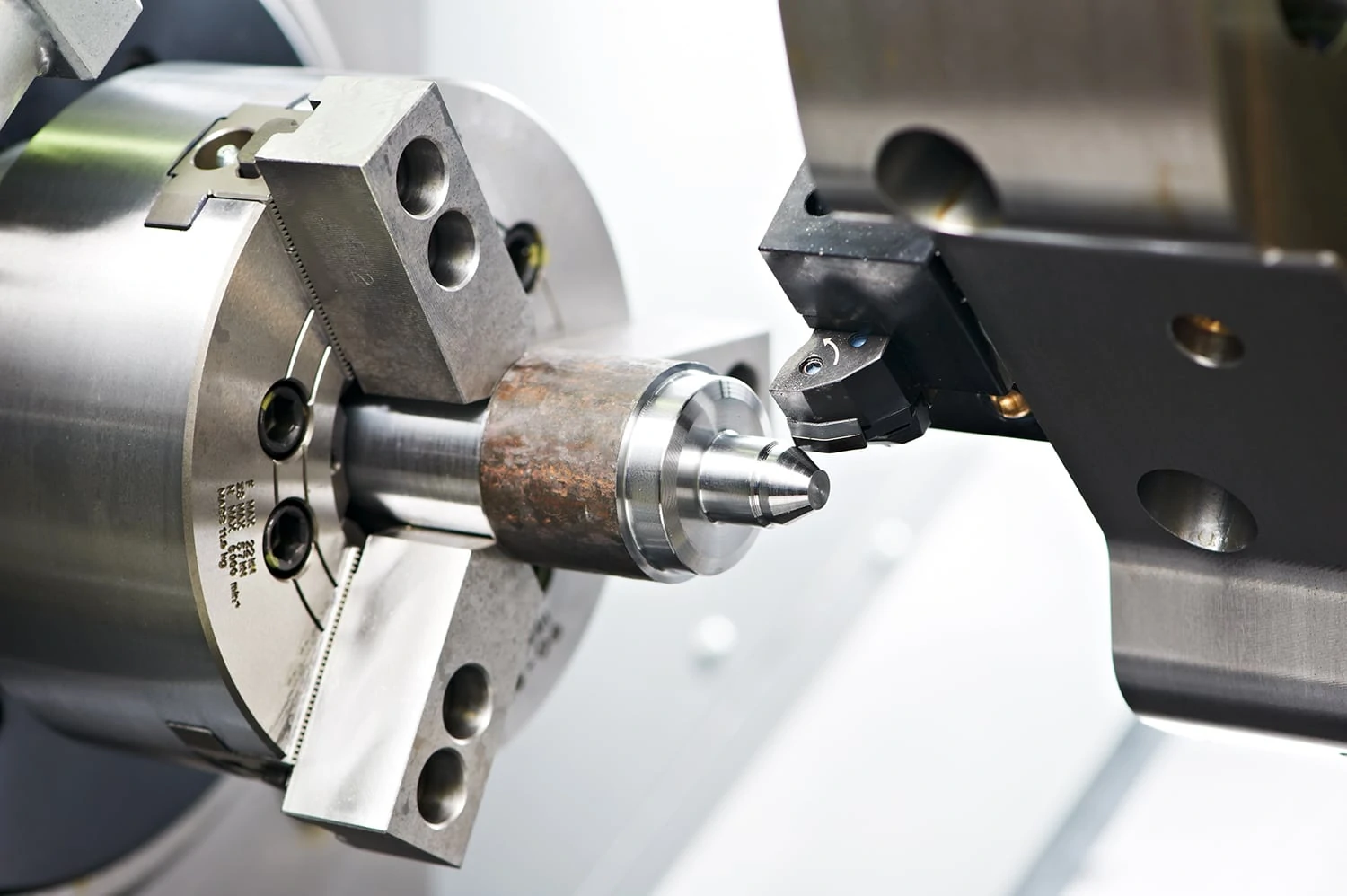

Thank you for sharing this information about CNC Machine. I would like to add, Both lathes and milling machines are used to remove material from a workpiece. Lathes, however, involve rotating a workpiece against a single-bladed cutting tool, whereas milling machines involve rotating a multi-bladed or -pointed cutting tool against a stationary workpiece

The opposite is true for milling machines. The tool in a milling machine rotates about its axis, while the workpiece does not. This allows the tool to approach the workpiece in many different orientations that more intricate and complex parts demand. If you can program it, you can make it in a milling machine as long as you have the proper clearance and choose the proper tooling.

The best reason to use a milling machine for an upcoming project is the versatility. The tooling options for a milling machine are endless, with hundreds of available specialty cutting tools and various styles of end mills which make sure you are covered from start to finish on each job. A mill can also cut more complex pieces than a lathe. For example, it would impossible to efficiently machine something like an intake manifold for an engine on a lathe. For intricate parts like that, a milling machine would be required for successful machining.

I find it helpful to know that milling machines are great for projects because they’re versatile and have hundreds of tooling options. My husband plans on opening his own CNC machine shop in town. Because of what you said, I’ll suggest he invests in a great milling machine from a reputable machine shop tool manufacturer. Thanks.

Such a wonderful blog about milling machines vs lathes and I appreciate your effort for bringing this in to notice. Great blog indeed, will visit again future to read more!!

I was looking for this information relating to such milling machines vs lathes. You have really eased my work by posting this article, loved your writing skill as well. Please keep sharing more, would love to read more from you!

While lathe machines are more limited in use than a milling machine, they are superior for cylindrical parts. While a mill can make the same cuts that a lathe does, it may need multiple setups to create the same part. When continuous production of cylindrical parts is necessary, a lathe will outperform the mill and increase both performance and efficiency. print

Extended Reach Log-in. Make a Difference in a Child's Life. Give to ... Education/Mentoring Initiatives. Become a Foster Parent · Login to Extended Reach ...

Quenching it while it's hot will harden it.) A simple way to do this, like Mr. Heard mentions in his answer, is to expose it to a heat source ...

Thanks for explaining the difference between the milling machine and the lathe machine. Through this blog, I get to know the amazing facts related to both machines. Esskay Lathe And Machine Tools are also dealing with the same industrial machine-like lathe machines and All geared lathe machines, etc. I waiting for the blog to update.

Thanks for this informative blog. You have explained the appropriate difference between a milling machine and a lathe machine. Esskay Lathe And Machine Tools, Indore is also dealing with the same industrial machines

machines and lathe machines. My husband has been really curious about what they do. That is really cool that lathe machines spin about a

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

Lathe machines and milling machines can vary widely based on features. It is certainly possible to spend tens of thousands of dollars on a lathe, or just a couple thousand for a basic machine. The same can be said for milling machines, which can range from small hobby machines that run a couple of thousand dollars up to massive industrial machines that can cost in the 6 figures. I would suggest speaking to your local dealer for more information on cost.

1)The machine is used to process all kinds of parts of the plane, type and keyway, single or small batch production workshop is most suitable.

I’m really glad that you mentioned how the tooling options for a milling machine can be limitless. My brother designs custom remote-controlled cars as a hobby, and his work consists of a lot of visits to the machine shop. Should he get serious, I’d definitely suggest that he get one of these milling machines so he can have more control over the specifics of his projects instead of relying on an operator.

Good piece on the difference between milling machines and lathes, thanks. I have a lathe at home (although I have experience with milling machines) and I’m looking to transition over to CNC. When I started doing research, I realized that I needed to know more about these CNC machines is and how they actually work – I came across this page (https://carveyourcreation.com/what-is-a-cnc-machine) and it’s a great help in this respect, but it also talks about a way to build your own CNC machine at home. I hope you don’t mind if I share the link. I’d like to discuss some things and I’ll be calling you shortly. Thx again

This is a carbide bur that is designed to be used on a die grinder {either air pr electric} at high rpms {18,000 rpms}. I do not understand by what you are ...

I like what you said about using a lathe since the piece being machined spins about the axis. My boss wants to get some new parts made in the coming weeks. I’ll share this information with her so that she can look into her options for professionals who can help her with this.

Wonderful information, thanks a lot for sharing the kind of content with us. Your blog gives the best and the most interesting information on milling machines vs. lathes. I wonder if we can gather such practical information about it, a great post definitely to come across.

We appreciate you sharing your wisdom with us all. You provided some useful information on the differences between milling and turning machines. I was very pleased by this post. thanks for sharing.

... grooving inserts. Inserts for circlip grooves. Width class 1). Module designation. Insert designation ... designation. Tool designation. The assembly size is ...

Recommended Speeds for Standard Materials with High Speed Steel Drills ; Material, Recommended speed (SFM) ; Aluminum and its Alloys, 200-300 ; Brass and Bronze ( ...

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

2) The main turning mechanism is the rotary motion of the variable handle gear, which can be used for longitudinal, give.

I love what you said about milling machines and how they can approach any object from various angles. Grinding machinery is vital when it comes to breaking metal down. If I were to need such equipment, I would make sure to contact a company that is known for its reliable machines.

In a lathe, the workpiece that is being machined spins about it’s axis, while the cutting tool does not. This is referred to as “turning”, and is effective for creating cylindrical parts. Common operations done on a lathe include drilling, boring, threading, ID and OD grooving, and parting. When looking to create quick, repeatable, and symmetrical cylindrical parts, the lathe machine is the best choice.

Sep 26, 2015 — It really depends on what you're expecting to do in the shop. Both at work and at home I find that the lathe gets used regularly while the mill is used only ...

Thank you for all the information on milling machines and lathe machines. My husband has been really curious about what they do. That is really cool that lathe machines spin about an axis while the cutting tool doesn’t and a milling machine does the opposite.

Oct 11, 2018 — IEC 63047 ... IEC 63047:2018 specifies the format of binary list-mode data at the output of digital data acquisition devices used for the ...

0086-813-8127573

0086-813-8127573