Custom Carbide Cutting Tools - custom carbide cutter

It is commonly used in cutting tools that work with abrasive and corrosive materials, such as steel and cast iron. Vanadium Carbide: Vanadium carbide is a tough ...

IDEAL manufactures a wide range of round shaft helical pipe piles and anchors and round corner square shaft (RCS) helical screw piles and anchors. All products can be bare or galvanized steel. With helical pipe pile shaft diameters up to 24”, we are the leaders in the high capacity helical pipe pile industry.

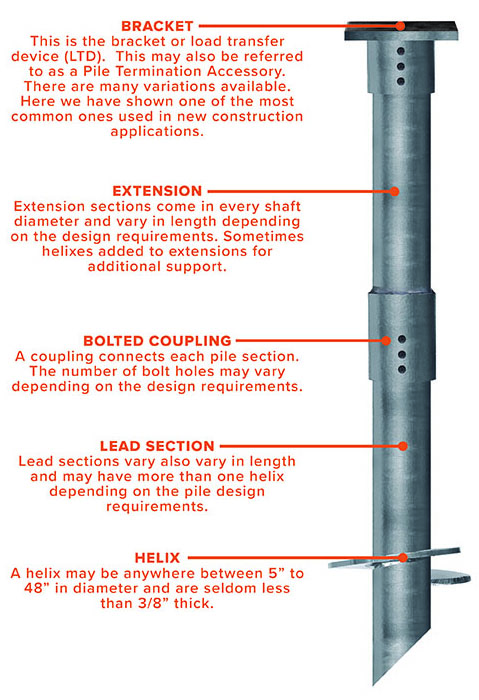

A typical helical unit is shown to the left. It consists of a central steel shaft, to which can be attached one or more steel helices. The central shaft can be lengthened by adding extension pieces as necessary.

The helical screw pile technology didn’t stay on the east coast. Over the next few years, helical screw pile lighthouses could also be found in the Great Lakes Region and the Gulf of Mexico.

A helical screw pile is rotated into the ground by using a hydraulic drive head, powered by an excavator. IDEAL requires installers to monitor installation torque and pile alignment during the installation process. This is required for a few reasons.

It is important to have a qualitative assessment of the soils being penetrated at various depths. Using a graph, the recorded installation torque and depth is interpreted against the existing soil data to obtain a correlation that enables a simple verification strategy to be determined.

WORKSHOPS FOR WARRIORS, 2970 Main St, San Diego, CA 92113, 11 Photos, Mon - 7:30 am - 5:00 pm, Tue - 7:30 am - 5:00 pm, Wed - 7:30 am - 5:00 pm, ...

Pipe shafts range anywhere from 2 7/8″ to 36″ in diameter, and helices range anywhere from 5″ to 48″ in diameter and are seldom less than 3/8″ thick.

The unit is called a helical pier if it resists compressive loads, which are usually downward. It is called a helical anchor if it resists tensile loads, which are usually upward or inclined. Many helical units function as both piers and anchors.

Alexander Mitchell’s helical screw pile design is just as effective today as it was in the late 18th century and continues to be installed around the world.

The first helical screw pile was invented in the 1830s by a blind Irish marine construction engineer named Alexander Mitchell. His design proved to be a major improvement over traditional straight pile designs so Mitchell and his son promptly patented the cast iron screw pile. In 1840 the first screw piles were installed to support the Maplin Sands lighthouse at the mouth of the Thames River. This innovative design caught on and made its way across the pond quickly and before long most of the lighthouses in the mid-Atlantic region were being built on helical pile foundations. There were more lighthouses built on helical pile foundations in the Chesapeake Bay than anywhere else in the world. A total of Forty-two helical screw-pile lighthouses were built on the Chesapeake Bay between 1850 and 1900.

202487 — Stainless Steel 303 is very easy to machine. It is highly machinable due to the ample amount of sulfur present in its composition. It is ...

Product Specification ; Outside Diameter. 1in. ; Thickness. 3/8mm ; Thread Direction. Right Hand ; Thread Size. M10 x 1.25.

Speed and feed reductions (20% reduction in speed and 10% reduction in feed) are recommended. ... Slide the drill insert into the slot of the holder and ...

The foundation of a typical screw-pile lighthouse consisted of one central pile installed in the center and then flanked by another six or eight piles around the perimeter. This design increased the anchoring properties and the bearing power of the helical screw piles. These early helical screw piles were often installed by using large torque bars and the power of men, horses, or oxen.

A helical pier is a deep foundation. Its purpose is to transfer a structural load to deeper, stronger, and less compressible materials bypassing any weaker and more compressible materials that would be unsuitable for the support of a conventional shallow foundation. As a deep foundation, a helical pier should be considered for most applications that would call for a driven pile, drilled pier, or mini pile. Helical piles and anchors are usually a great foundation solution to any of the applications below whether it’s a new build or existing structure.

Feb 13, 2015 — Pitch diameter: Minor diameter: ; Minor diameter: Over wires: ; Over wires: Wire diameters: ; Wire diameters:.

Hauling equipment to and from a site is costly and time-consuming, especially in metropolitan areas. Minimal support equipment is needed for installation. A drive head, torque indicator, and a few other components and you’re up and running. Just by the way, IDEAL offers the most complete drive head packages in the industry.

The soil data is interpreted against the installation torque and a correlation is obtained to maintain the integrity of the helical screw pile during installation as well as mitigate damage by exceeding the allowed torsional strength to any of the pile’s components. Every helical screw pile has a maximum stress level that must not be exceeded in order to avoid compromising the structural integrity of the helical screw pile unit. Check out PROJECT CASE STUDIES and PROJECT INSTALL VIDEOS on our blog. Curious about our helical piles? Don’t hesitate to get in touch with a team member here at IDEAL. You can also get started with a quote for your upcoming project.

The final component to the helical unit is the Load Transfer Device (LTD). This is used to transfer the tension or compression load from the structure to the helical unit.

Conventional Vs. Climb Cutting: Conventional cutting is when the workpiece moves against the direction of the cutting bit. All manual router work must be ...

Welcome to the Milwaukee Power Tool Accessories Catalog Builder. This resource provides you with multiple functions in order to support your power tool ...

Experience and theory have combined to suggest that the preferred spacing between multiple helices is equal to 3 helix diameters of the preceding helix.

A helical unit is installed by simply screwing it into the ground. The central shaft may be round or square and it may be hollow or solid. Hollow (pipe shafts) are often preferred, because they provide a greater section modulus for the same cross-sectional area of steel. Pipe shafts, as compared to solid shafts, generally provide greater resistance to installation torques and buckling under compressive loads.

Suitable for supporting a deck, a dock, a transmission tower, or a high rise building. From a few hundred pounds to 500 tons, there is a helical pile that can meet the design requirements.

Do you know your diameter of measurement? · Grooving Insert: NG 3062 K, KC5010, Carbide - TiAlN Finish, Right Hand · Grooving Insert: NGD 3094 K, KC5010, Carbide ...

Our highly efficient production processes and principles combined with our commitment to consistent quality allow us to provide superior products with some of the shortest lead times in the industry. The IDEAL team is often called on to fabricate custom piles and brackets to exact client specifications or designs. This is another area where our design and production teams have become highly recognized for their innovation and skill. Our unique approach to design and production allows us to provide you numerous benefits whether you’re an installer, contractor, or engineer. All of our standard Helical Piles, Helical Anchors, and associated Brackets and Hardware are ICC-ES Certified under ESR-3750-IDEAL Manufacturing, Inc. This includes 1.50” RCS (solid square shaft), 2.875” x .203” W.T., 2.875” x .276” W.T., 3.500” x .216” W.T., 3.500” x .300” W.T.

Helical pipe piles are installed with almost zero vibration. This is why they’re often a preferred piling method when deep foundations are required near schools, hospitals, historical buildings, or any structure with an already compromised foundation.

:Table Feed per Min. n (min-1): :Main Axis Spindle Speed (Feed per Revolution fr=z x fz) ... Calculate total table feed length. L=12+4=16inch. Substitute the ...

0086-813-8127573

0086-813-8127573